Slurry water recovery device for premixed concrete and use method of slurry water recovery device

A technology of ready-mixed concrete and recycling device, which is applied in the direction of clay preparation device, cement mixing device, mixing operation control device, etc. It can solve the problem that the slurry water cannot be reused, and achieve the effect of increasing the pre-tightening force and reducing the friction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

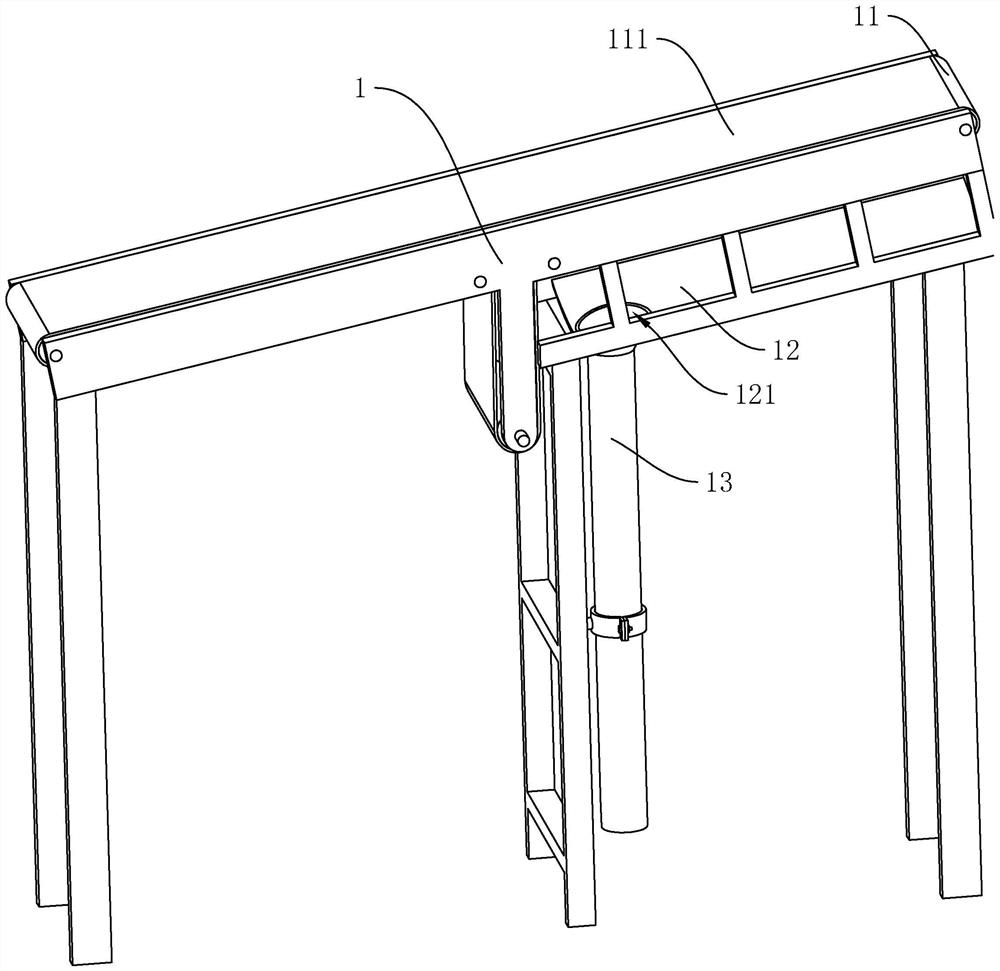

[0052] refer to figure 1 , a slurry recovery device for ready-mixed concrete includes a conveyor belt 111 and a rolling roller 11 arranged on a support frame 1, the top of the support frame 1 is inclined, and the conveyor belt 111 is sleeved on the rolling roller 11, the embodiment of the present application The middle conveyor belt 111 rotates clockwise, and the deflector 12 used to divert the residual pulp water to one place is welded on the support frame 1, and the deflector 12 is arc-shaped, and the deflector 12 is along the width direction. The two ends extend obliquely upwards, and the top wall near the bottom of the deflector 12 is penetrated with a slurry outlet hole 121 , and the slurry outlet 121 is used to discharge the slurry water on the deflector 12 . The support frame 1 is fixedly provided with a recovery pipe 13 along the vertical direction, and the recovery pipe 13 is coaxial with the slurry outlet 121. The recovery pipe 13 is used to transport the residual sl...

Embodiment 2

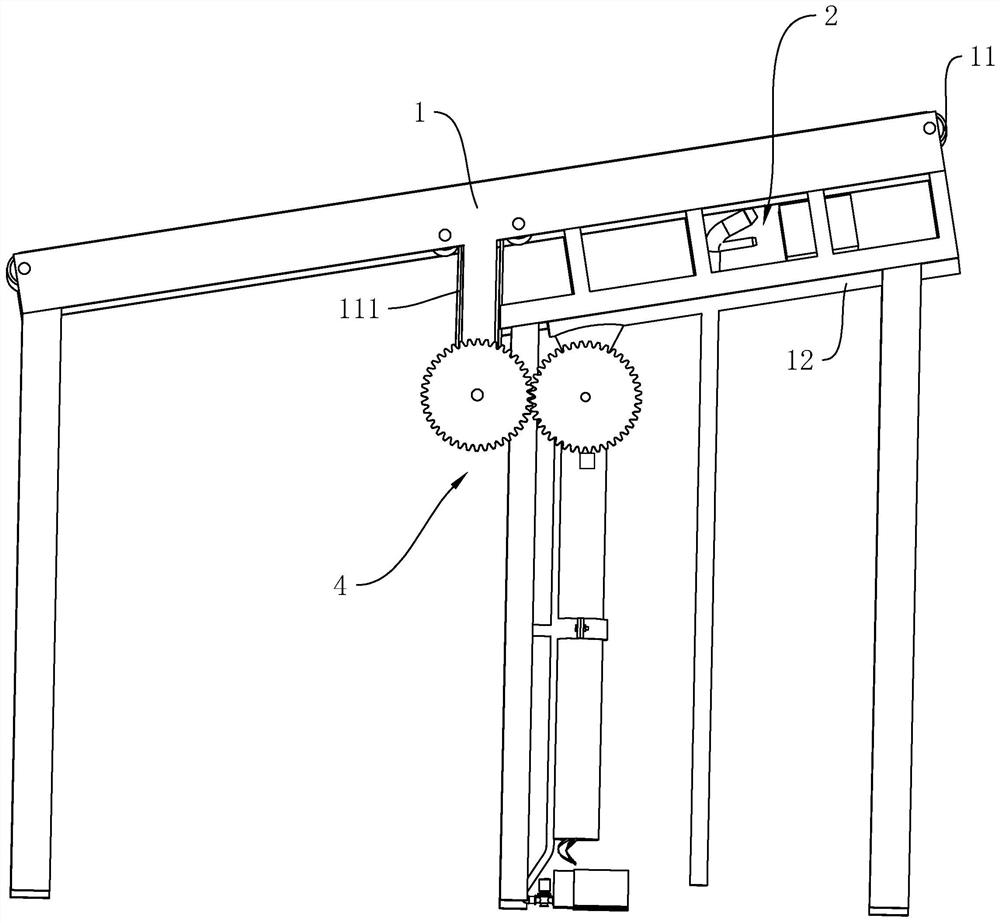

[0055] refer to figure 2 The difference between this embodiment and Embodiment 1 is that the deflector 12 is provided with a cleaning assembly 2 for cleaning the surface of the conveyor belt 111, and the cleaning assembly 2 can flush the mud adsorbed on the conveyor belt 111 to the flow guide Plate 12, so as to further recover the mud.

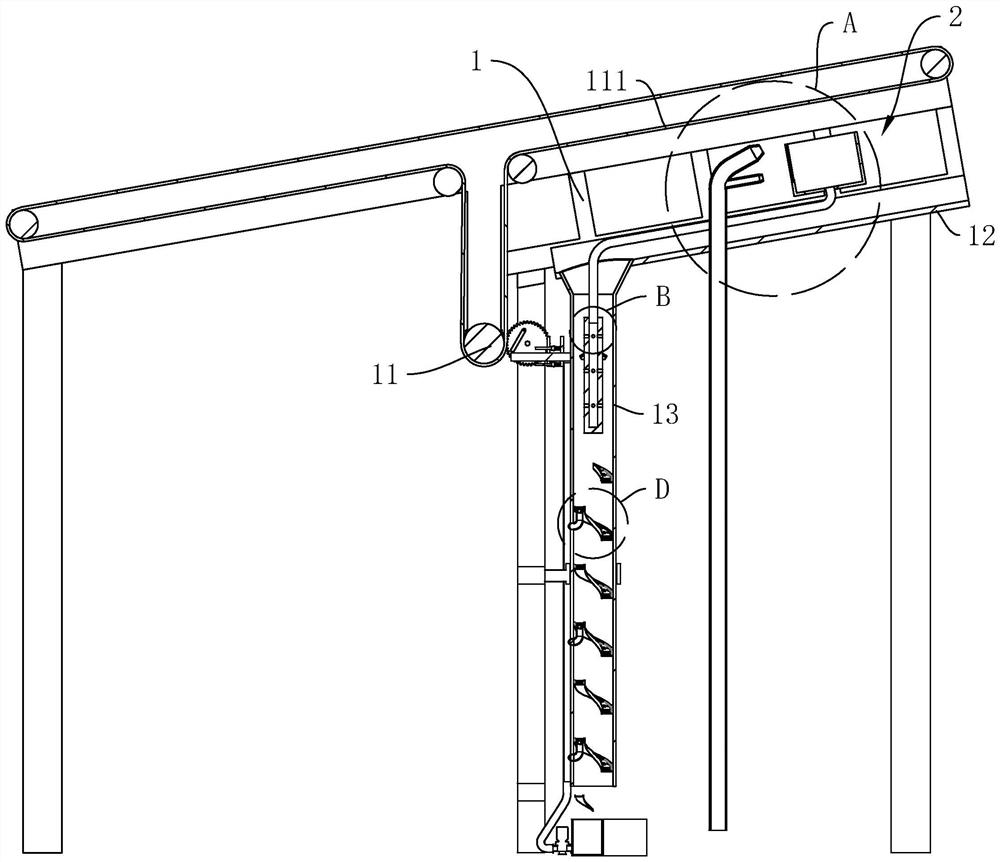

[0056] refer to image 3 and Figure 4 The cleaning assembly 2 includes a water inlet pipe 21, a first nozzle 22, a flushing pipe 23, a second nozzle 24, a filter plate 25, an outlet pipe 26 and a sump body 27, and the water inlet pipe 21 is welded with the deflector 12 in the vertical direction Fixed and run through the deflector 12, one end of the water inlet pipe 21 extends above the deflector 12, and the other end extends to the ground. The opening of the first nozzle is fixedly connected with the first nozzle 22, the nozzle of the first nozzle 22 faces the bottom wall of the conveyor belt 111, the water inlet pipe 21 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com