Carriage plate and production process thereof

A compartment panel and compartment panel technology, which is applied to vehicle components, superstructures and superstructures of trucks, etc., can solve the problems of easy water seepage, self-heavy weight, and increased labor costs in the spliced compartments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

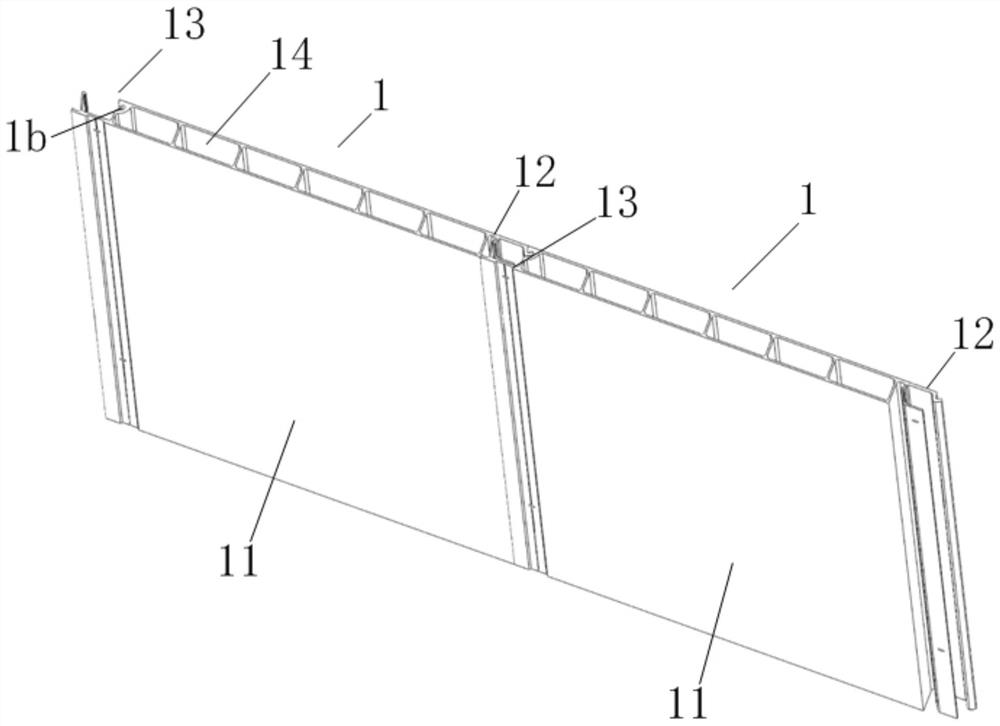

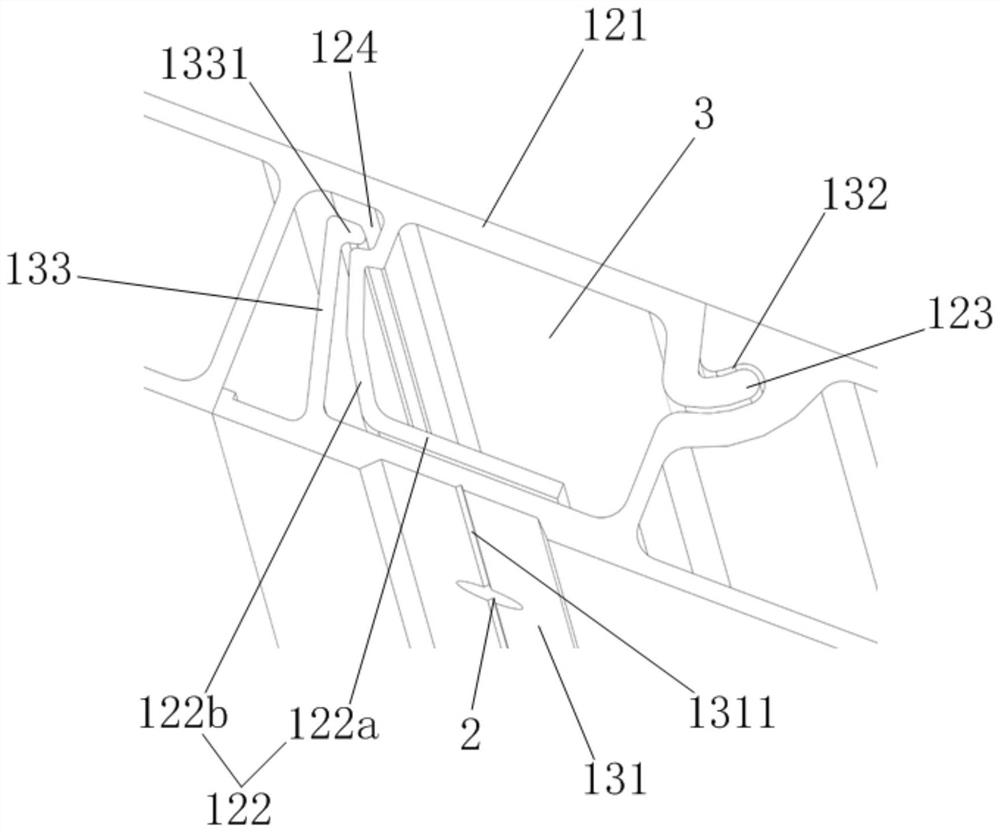

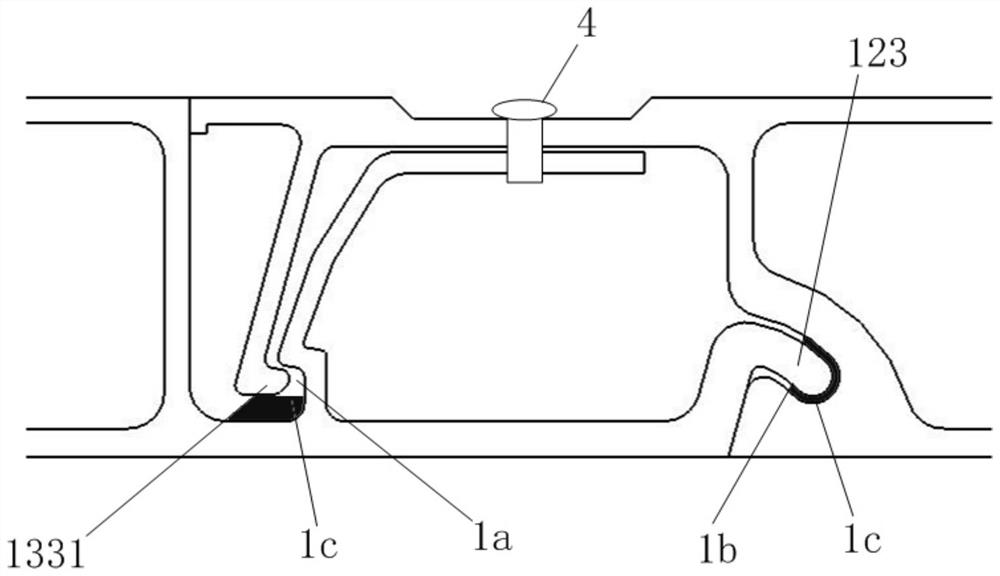

[0041] see figure 1 , 2 and image 3 , the present invention provides a compartment panel, comprising a plurality of compartment panel units 1 spliced end to end, said compartment panel unit comprising a panel body portion 11 and a first splicing end 12 and a second splicing end 13, said first splicing end 12 and the second splicing end 13 are respectively arranged on both sides of the said panel body portion 11, adjacent to the two single compartment panel units 1, the first splicing end 12 of one compartment panel unit and the second splicing end 13 of the other compartment panel unit terminal connection;

[0042] Wherein, the first splicing end 12 includes an outer edge 121, an inner edge 122, and a fastening groove 124 provided with a fastening space 1a, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com