Water turbine type aircraft constant torque arresting adjusting system

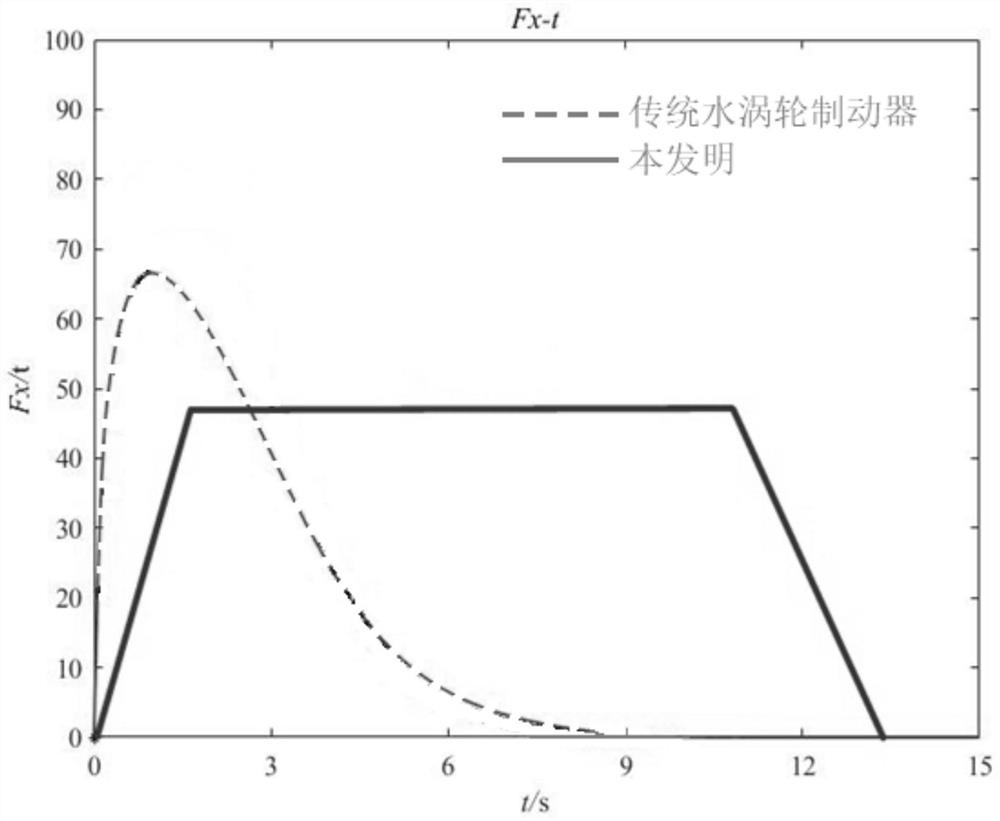

An adjustment system and constant torque technology, applied in the direction of the stop device, etc., can solve the problems of reducing the service life of the aircraft, adjusting the resistance of the aircraft, and poor economy, and achieve the effects of reducing physical discomfort, reducing peak load and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

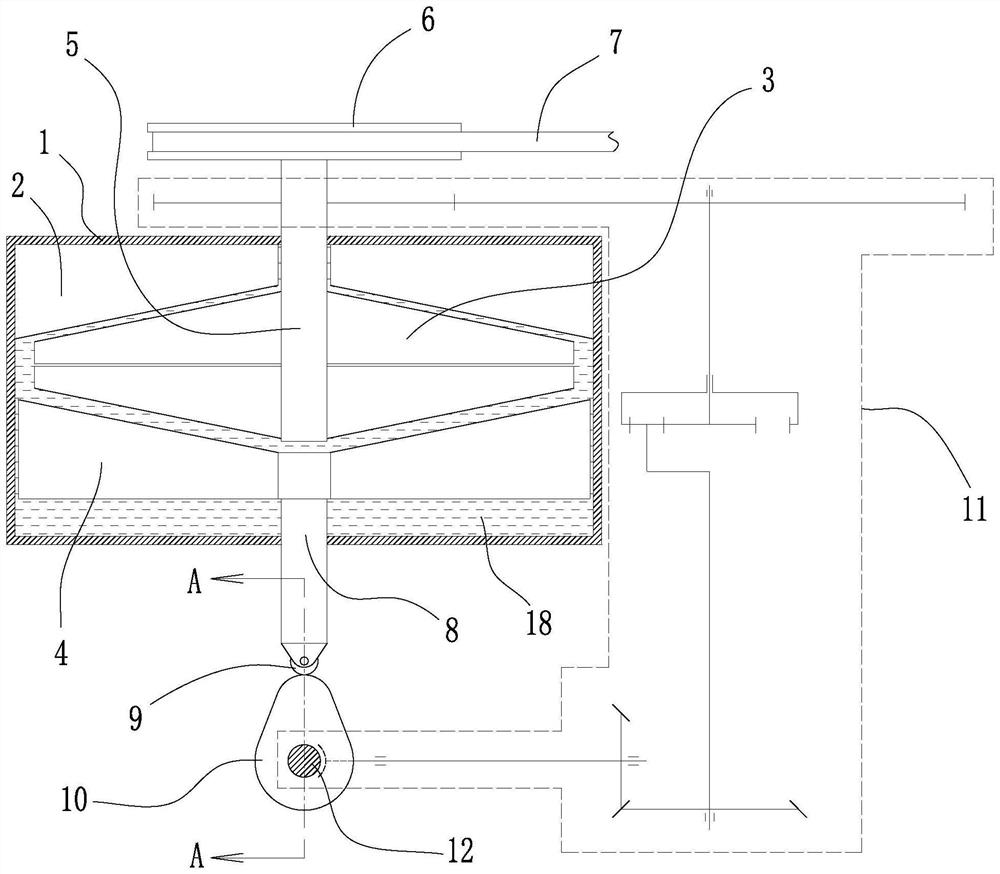

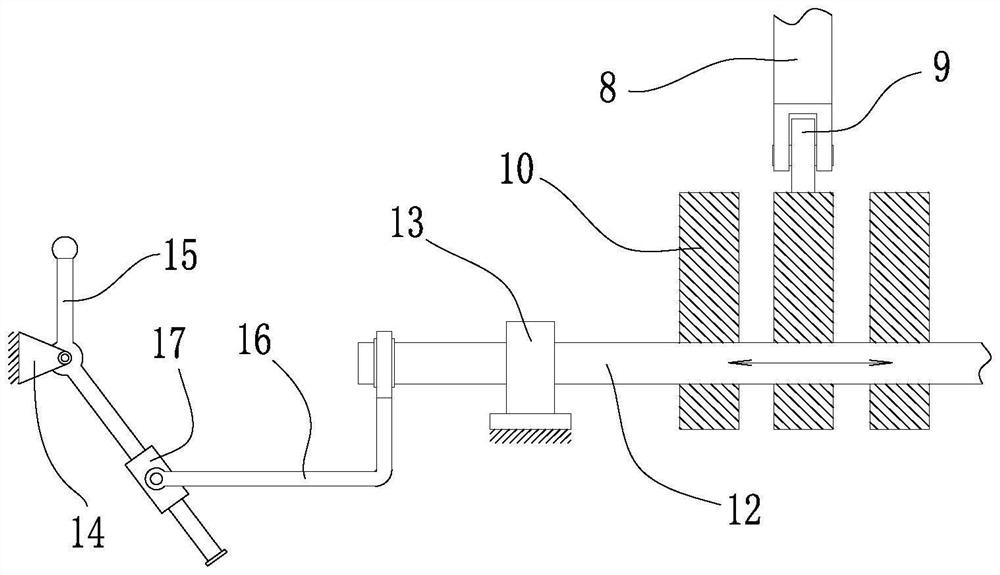

[0017] Such as figure 1 , 2 As shown, a water turbine type aircraft constant moment arresting adjustment system includes a housing 1, an upper stator 2, a rotor 3, a lower stator 4, a rotating shaft 5, a cable reel 6, an arresting belt 7, a push rod 8, a roller 9, Cam 10 and deceleration mechanism 11; the sealed space inside the housing 1 is filled with a fluid medium 18; the upper stator 2 is located inside the housing 1, and the upper stator 2 is fixedly connected to the lower surface of the top plate of the housing 1; the rotor 3 is located inside the housing 1 and below the upper stator 2, the rotating shaft 5 seals through the top plate of the housing 1 and extends to the inside of the housing 1, the rotor 3 is fixedly connected to the rotating shaft 5, and the rotating shaft 5 has a degree of freedom of rotation; The lower sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com