Powerful deviation rectifying device capable of quickly realizing bidirectional automatic aligning

An automatic centering and deviation correcting device technology, which is applied in the direction of transportation and packaging, conveyor objects, conveyors, etc., can solve the problems of difficult processing of friction wheels, increased operating costs, and easy damage to conveyor belts, so as to eliminate sliding friction , reduce operating costs, and prevent damage to equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings.

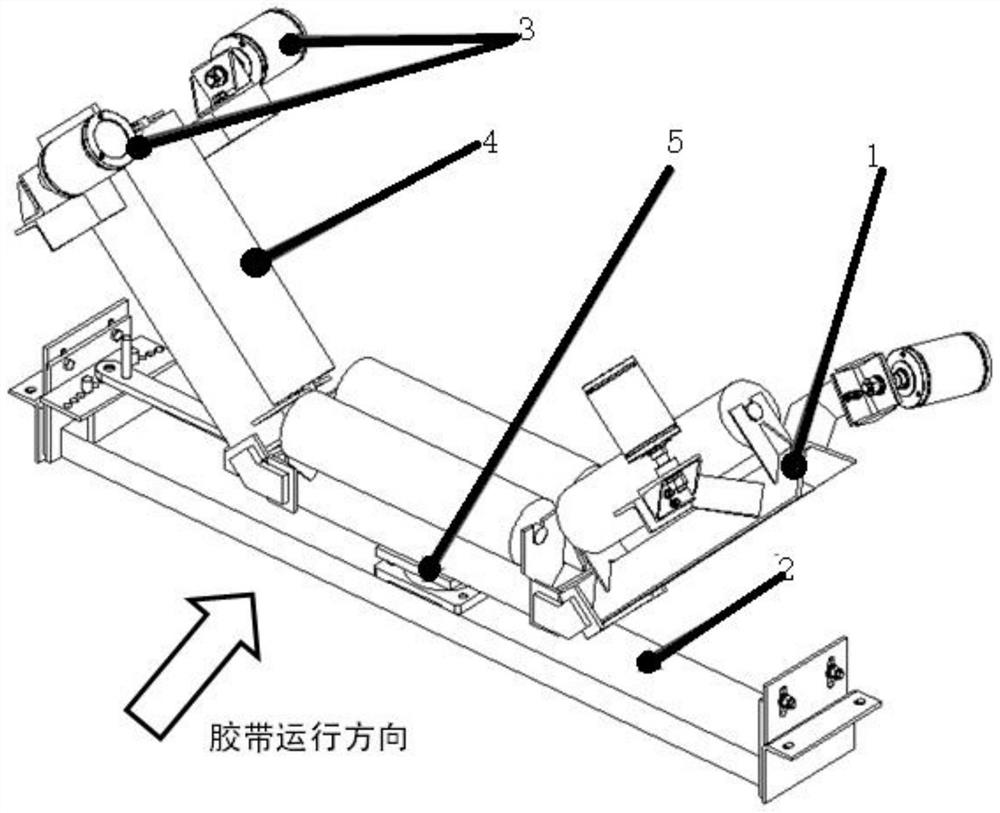

[0045] refer to Figure 3-Figure 12 As shown, a powerful deviation correction device that quickly realizes two-way automatic centering includes the main body of the device, and the main body of the device includes:

[0046] The vertical roller 3 is used to detect the deviation and transmit the torque to the flat roller part;

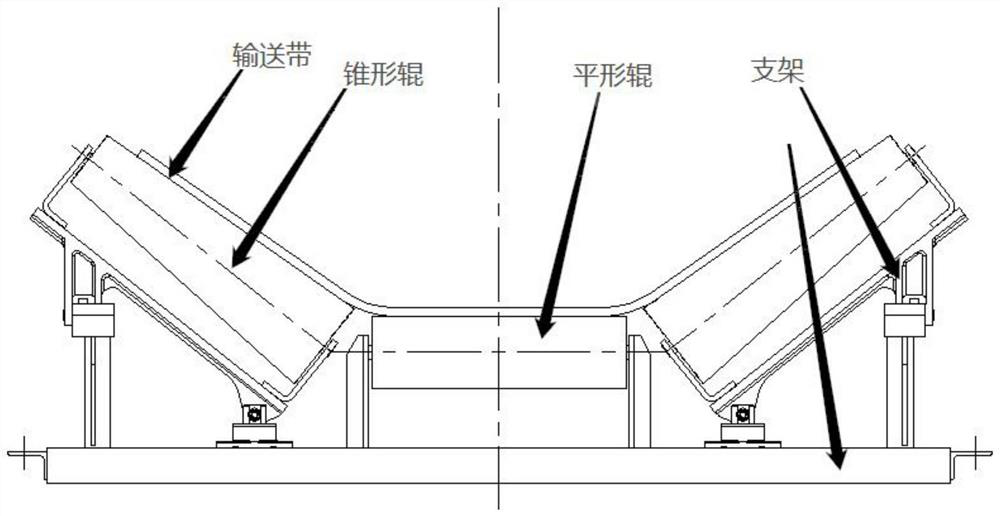

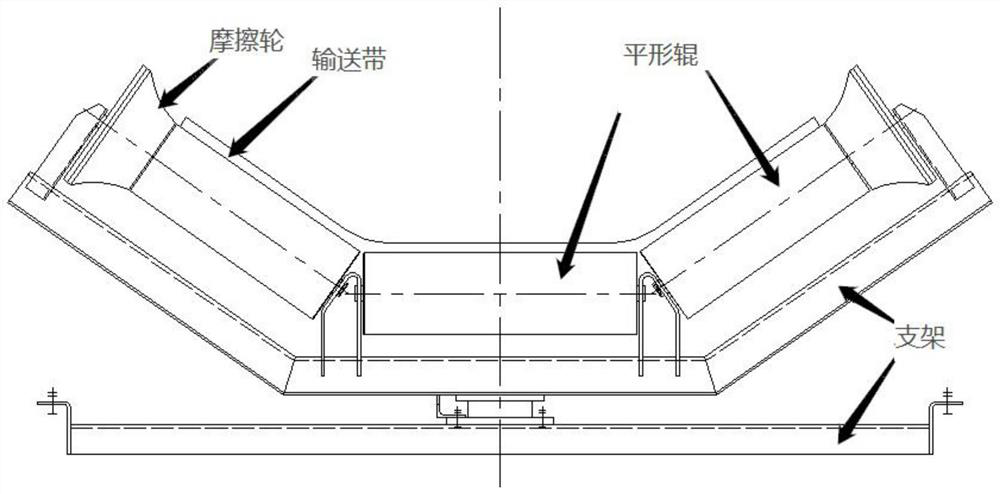

[0047] Flat roller 4 is installed on the upper support to form a groove angle for carrying the conveyor belt;

[0048] The upper bracket 1 is used to install and support the roller part;

[0049] The lower bracket 2 is used to support the upper bracket, and the lower bracket part is composed of a hanger 14 and a beam 13;

[0050] The fulcrum steering seat 5 contains bearings and is used to connect the upper and lower brackets;

[0051] The upper bracket, the lower bracket and the fulcrum steering seat are assembled, and then 4 sets of vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com