Rapid production equipment for self-adhesive paper

A kind of production equipment and fast technology, which is applied in the direction of coiling strips, thin material processing, transportation and packaging, etc., can solve the problems of slow manual replacement and affect the efficiency and time of self-adhesive paper production, so as to save manpower, The structure is simple, the effect of improving production efficiency and production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

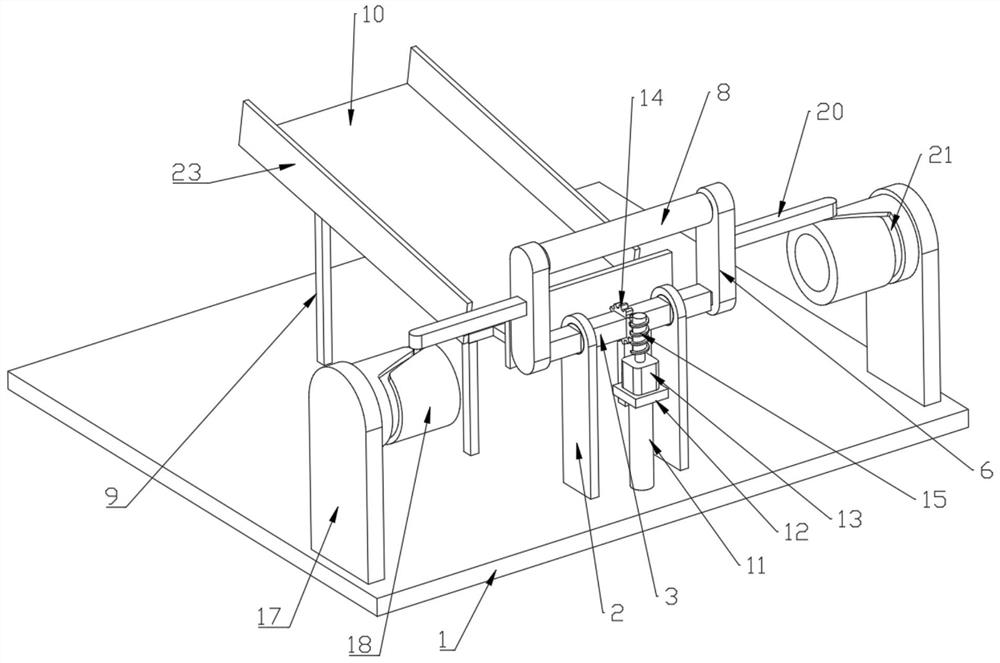

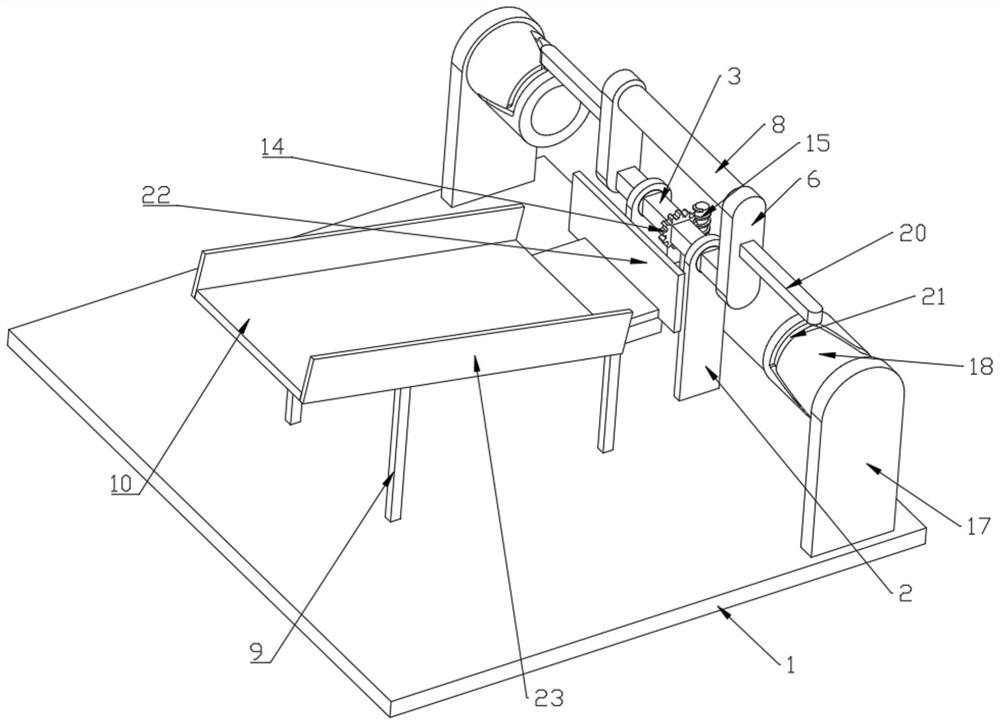

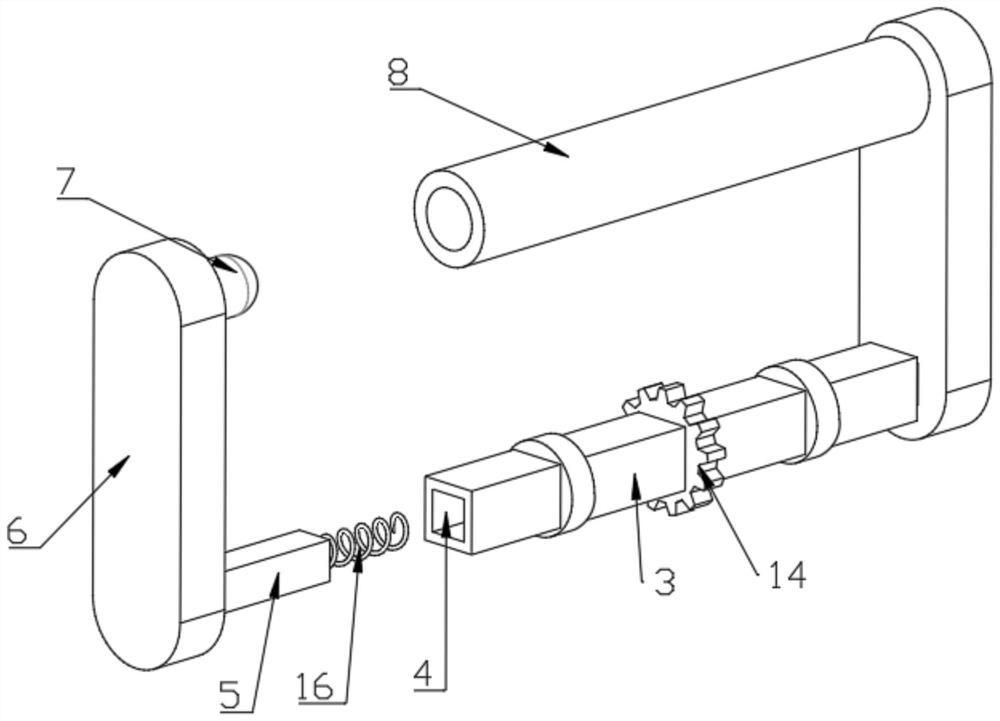

[0022] see Figure 1~4 , in an embodiment of the present invention, a rapid production equipment for self-adhesive paper, including a bottom plate 1, the upper end of the bottom plate 1 is fixedly connected with a first support column 2, the surface of the first support column 2 is rotatably connected with a first rectangular rod 3, the first The left and right sides of the rectangular rod 3 are symmetrically provided with a rectangular groove 4, and a second rectangular rod 5 is slidingly connected in the rectangular groove 4, and the other end surface of the second rectangular rod 5 is fixedly connected with a turret 6; the left and right turrets 6 are close to each other A clamping block 7 is fixedly connected to the surface of one end, and a roller 8 is arranged between th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap