Thin-wall metal mechanical property changing method

A metal and mechanical technology, applied in the field of changing the mechanical properties of thin-walled metals, can solve problems such as difficult application of metal parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

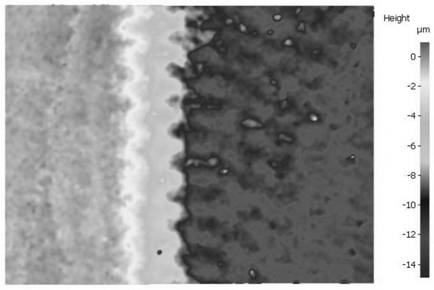

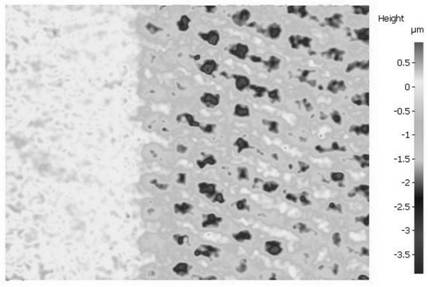

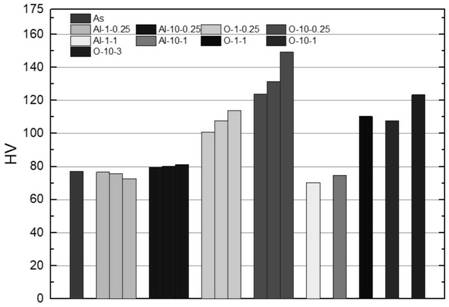

[0056] In order to quickly verify the effect of the ultrafast laser shock of the present invention on improving the fatigue resistance of metal materials (metal films), the present invention casts aluminum alloy specimens through ultrafast laser shock 7075 and tests related mechanical parameters to directly obtain the effect of ultrafast laser shock on 7075 The influence of the mechanical properties of the cast aluminum alloy specimens is used to verify the potential application prospect of ultrafast laser shock on the fatigue resistance of metals.

[0057] In this example, the effects of using aluminum foil as a sacrificial layer and direct laser irradiation on the mechanical properties of a cast aluminum alloy with a thickness of 0.25mm and 1mm will be investigated.

[0058] Ultrafast laser parameters:

[0059] Laser wavelength 1030nm; pulse width 290fs; single pulse energy 50μJ; pulse frequency 2kHz; spot diameter 60μm.

[0060] Spot overlapping method see image 3 shown....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap