Safety protection operation method for carrying out support padstone construction on bent cap

A safety protection and girder covering technology, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of small safety protection, single protection effect, difficulty in guaranteeing the personal safety of construction personnel and surveyors, and achieve easy dismantling , Guaranteed aesthetics and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] see Figure 1 to Figure 10 , the first embodiment of the present invention proposes a safety protection operation method for the construction of bearing cushion stones on the cover beam, the method includes the following steps:

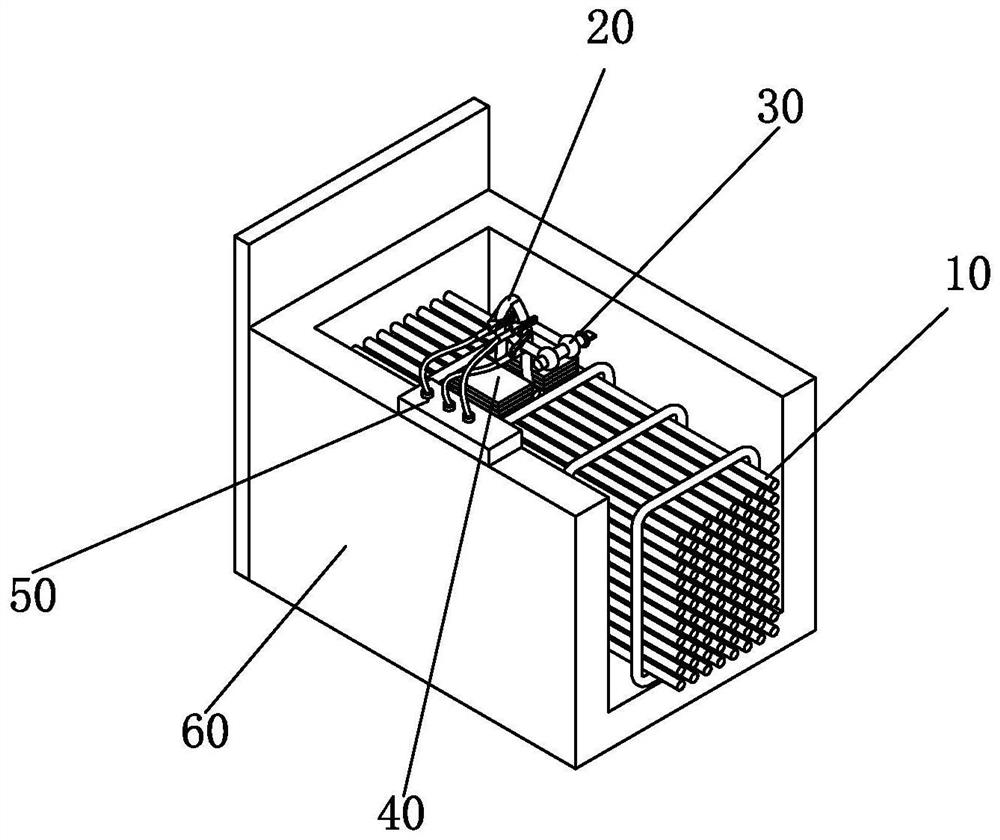

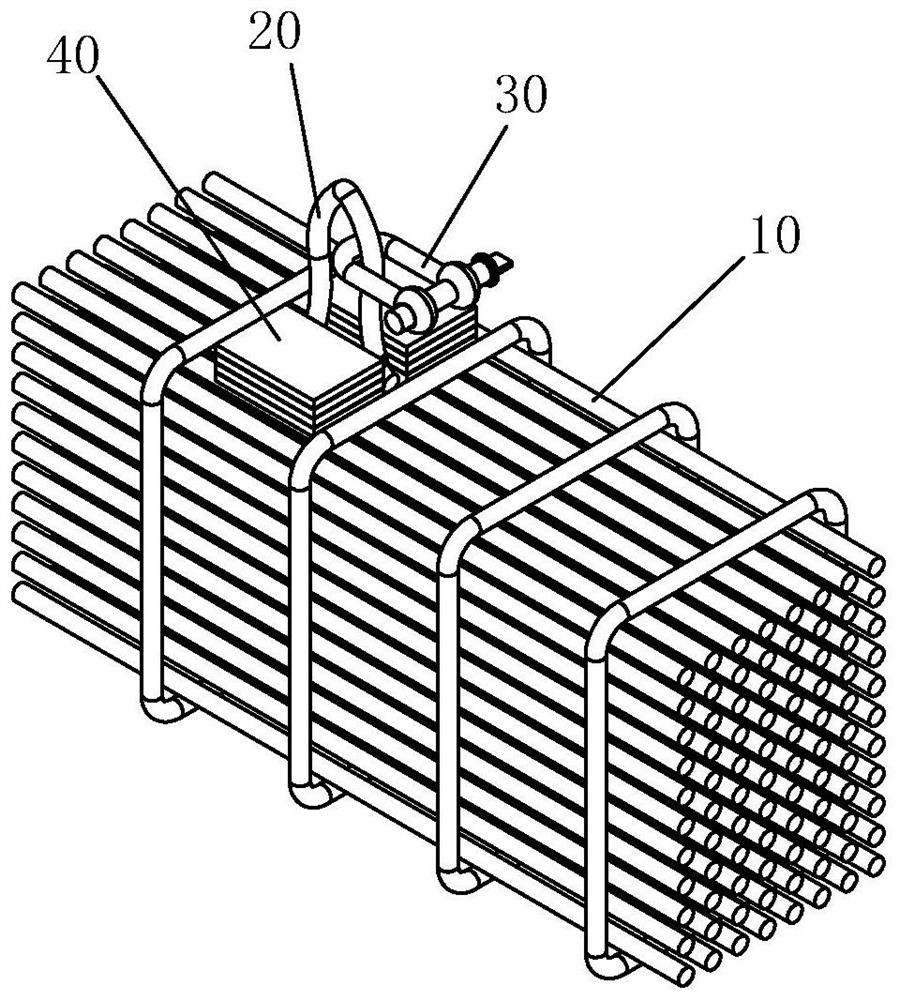

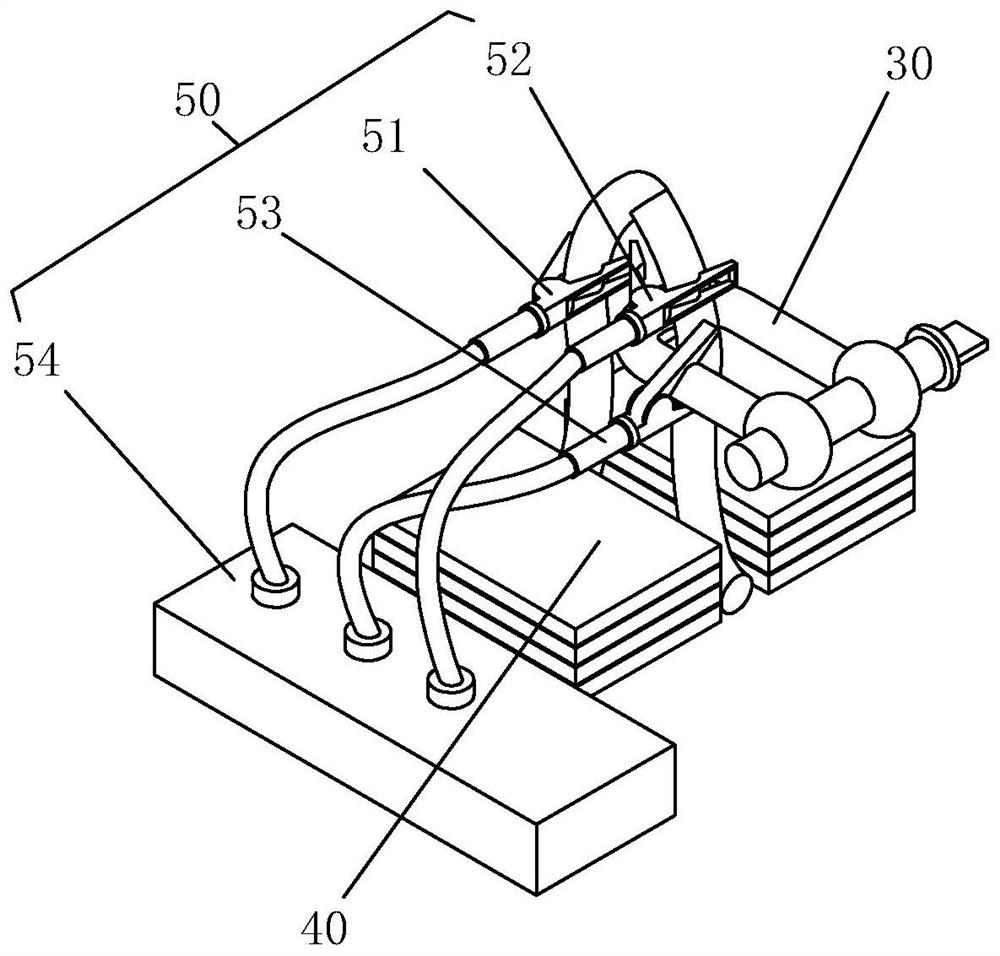

[0045]Step 1, install the block main reinforcement 10 in the cover beam template 60, pre-embed the safety ring 20 on the upper surface of the block main reinforcement 10, so that the safety ring 20 is pre-embedded in the forward section of the beam erection direction, wherein the cover beam The template 60 is used for integrally pouring the cap beam 200 and the stopper 100, and the main rib 10 of the stopper is located at the position of the stopper 100;

[0046] Step 2: install the notch plate 40 at both ends of the safety ring 20 installed in the step 1, and pour the cover beam 200 and the stopper 100 in the cover beam formwork 60 to obtain an integratedly connected cover beam 200 and the stopper 100, and the safety ring 20 is integrated wit...

Embodiment 2

[0072] see Figure 1 to Figure 11 , the second embodiment of the present invention proposes a safety protection operation method for the construction of bearing cushion stones on the cover beam, the method includes the following steps:

[0073] Step 1, install the block main reinforcement 10 in the cover beam template 60, pre-embed the safety ring 20 on the upper surface of the block main reinforcement 10, so that the safety ring 20 is pre-embedded in the forward section of the beam erection direction, wherein the cover beam The template 60 is used for integrally pouring the cap beam 200 and the stopper 100, and the main rib 10 of the stopper is located at the position of the stopper 100;

[0074] Step 2: install the notch plate 40 at both ends of the safety ring 20 installed in the step 1, and pour the cover beam 200 and the stopper 100 in the cover beam formwork 60 to obtain an integratedly connected cover beam 200 and the stopper 100, and the safety ring 20 is integrated w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com