Construction method for hard rock deep foundation pit in limited blasting area

A construction method and technology for deep foundation pits, which are applied in basic structure engineering, excavation, construction, etc., can solve the problems of slow construction efficiency and high cost, and achieve the effects of fast construction progress, small vibration and saving construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

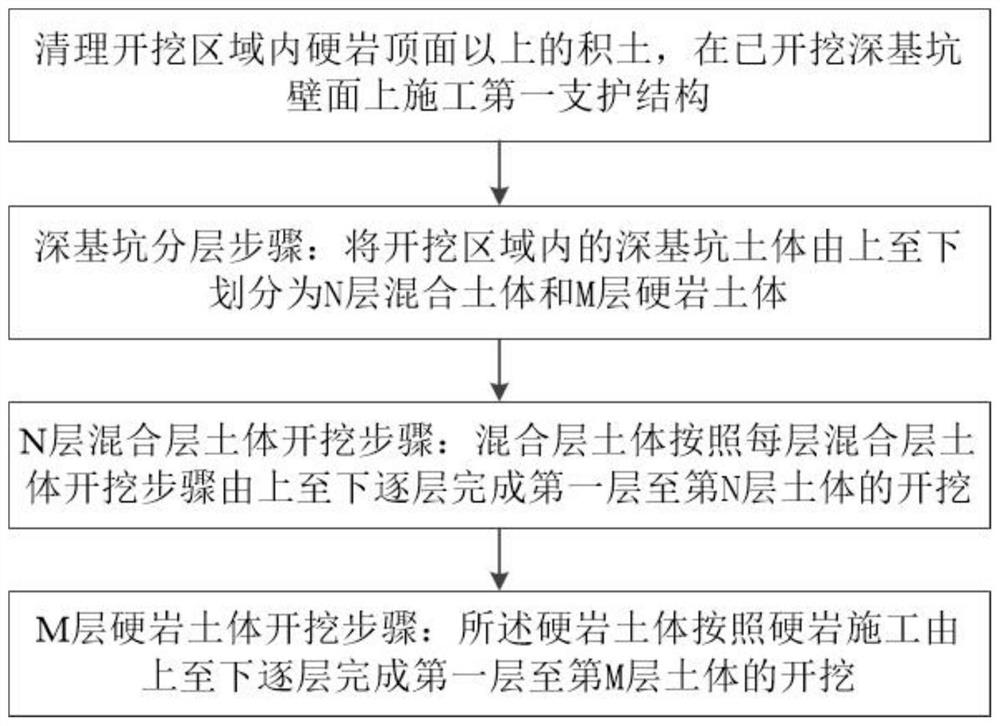

[0041] Such as figure 1 As shown, a hard rock deep foundation pit construction method in a restricted blasting area includes the following steps:

[0042] Clean up the accumulated soil 1 above the top surface of the hard rock 2 in the excavation area, and construct the soil support structure on the excavated deep foundation pit wall;

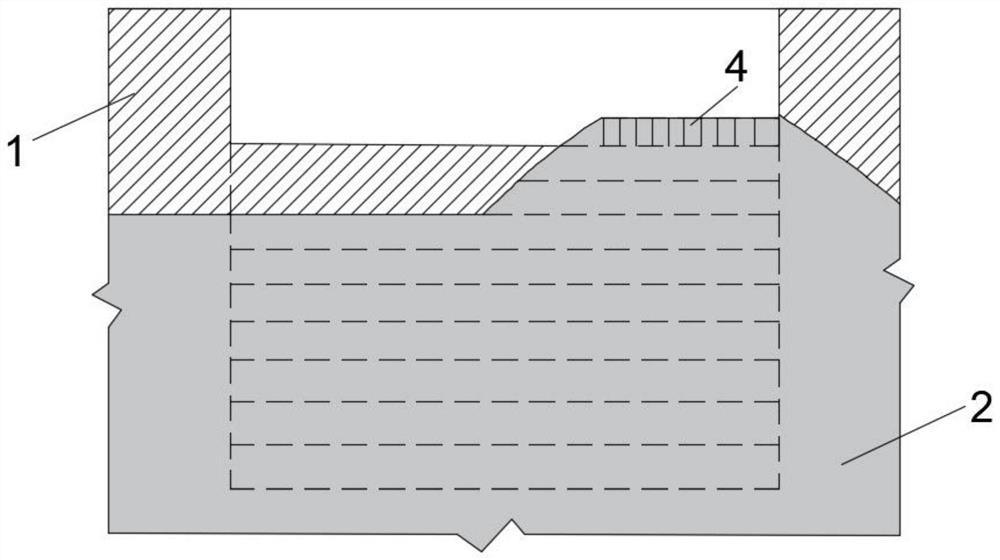

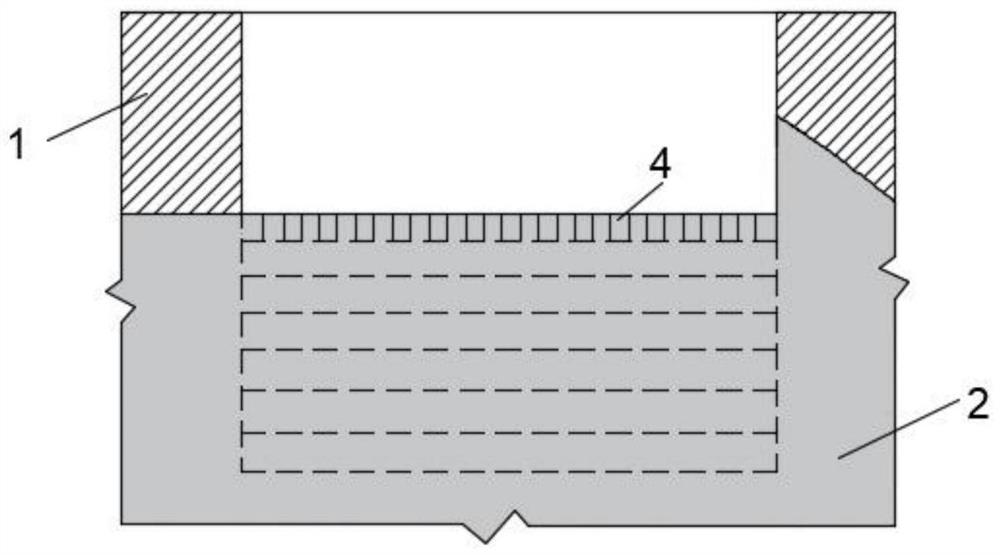

[0043] Deep foundation pit layering steps: After the supporting structure is completed in the excavated deep foundation pit, the deep foundation pit soil in the excavation area is divided into N layer mixed soil and M layer hard rock soil from top to bottom, as shown in figure 2 As shown, N is 3 layers, and M is 7 layers. Each layer of mixed soil includes accumulated soil 1 and hard rock 2, and each layer of hard rock soil is hard rock 2. The depth of each layer of mixed soil is 1.3mm. The depth of layer hard rock soil is 1.3mm.

[0044]Mixed layer soil excavation steps: the mixed layer soil is excavated from top to bottom layer by layer acco...

Embodiment 2

[0055] This embodiment is similar to Embodiment 1, and the difference is that this embodiment divides the deep foundation pit soil in the excavation area from top to bottom into N-layer mixed soil and M-layer hard rock soil, such as Figure 6 As shown, N is 4 layers, M is 8 layers, the depth of each layer of mixed soil is 1.5m, and the depth of each layer of hard rock soil is 1.5m.

Embodiment 3

[0057] This embodiment is similar to Embodiment 1, and the difference is that the deep foundation pit soil in the excavation area is divided into M layers of hard rock soil from top to bottom in this embodiment, such as Figure 6 As shown, the mixed soil layer is not divided, M is 5 layers, and the depth of each layer of hard rock soil is 1.8m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com