Automatic lifting suction device

A technology of suction device and suction pump, which is applied to components of pumping devices for elastic fluids, machines/engines, liquid fuel engines, etc., and can solve problems such as harsh operating conditions, poor mechanization, and large manpower consumption , to improve reliability, prevent clogging, and ensure stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

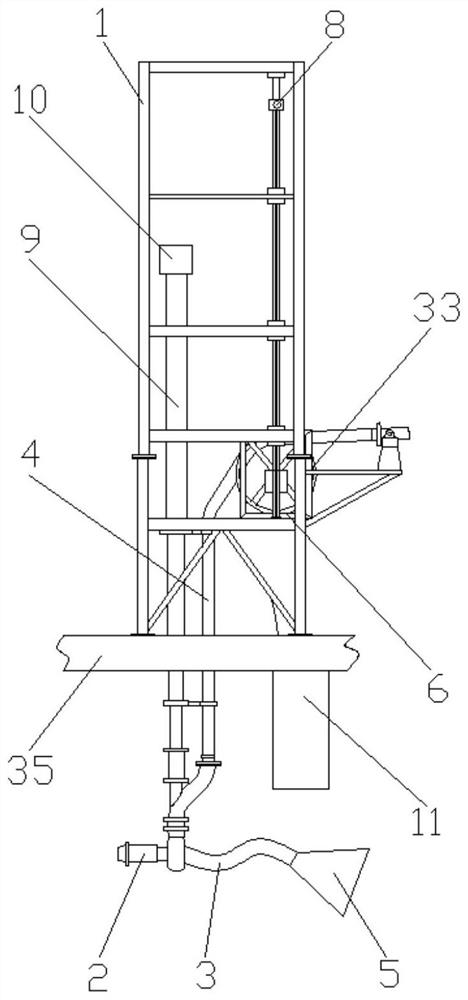

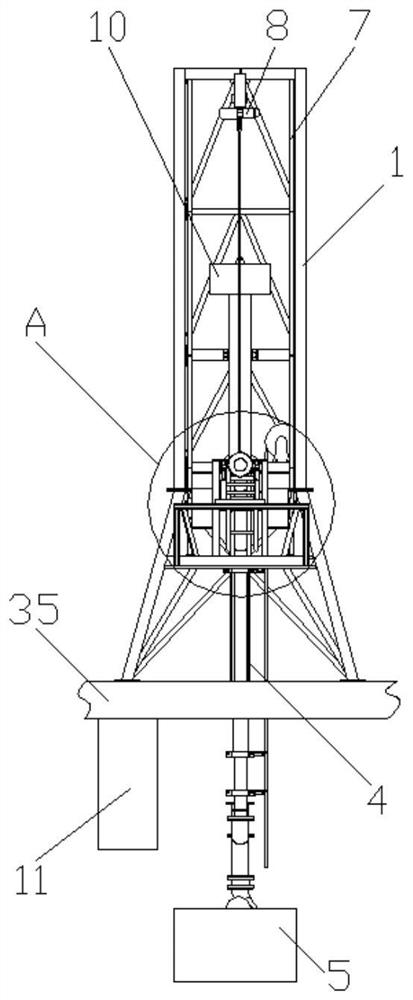

[0023] Such as Figure 1-4 As shown, an automatic lifting suction device in this embodiment includes a frame 1, a suction pump 2 is arranged below the frame 1, and a water inlet pipe 3 and a water outlet pipe 4 are respectively installed on the suction pump 2 , the end of the water inlet pipe 3 away from the suction pump 2 is equipped with a catcher 5;

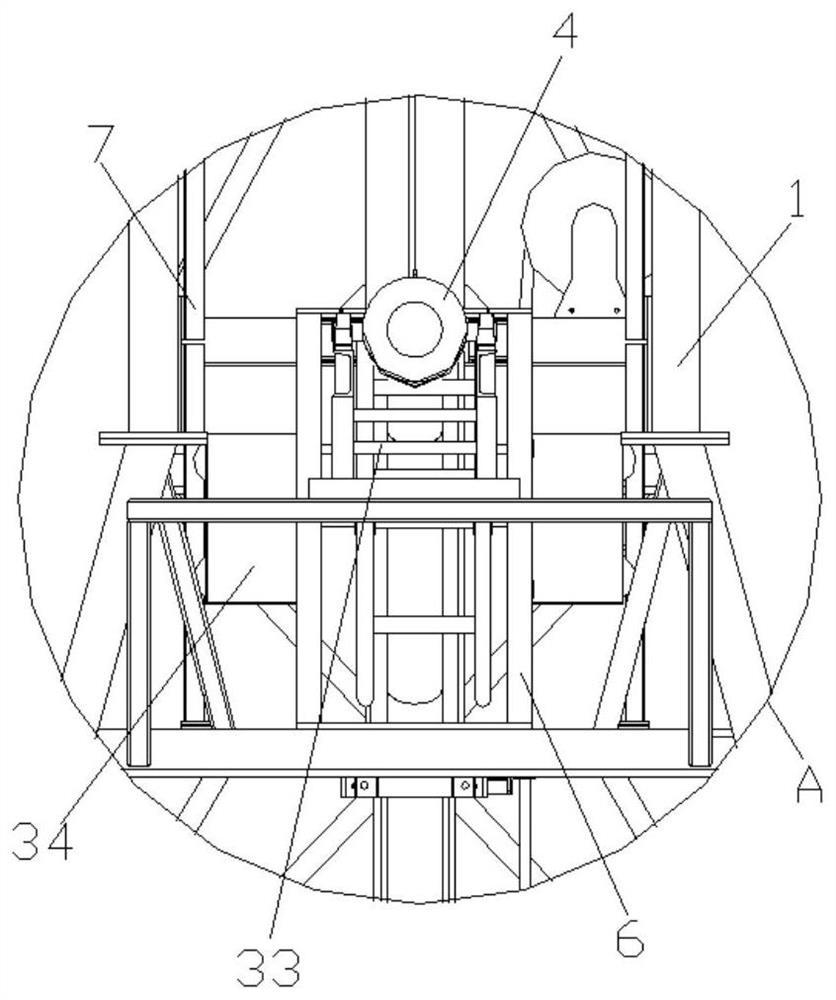

[0024] The frame 1 is provided with a hanging pan 6, the two sides of the hanging pan 6 are respectively connected to the frame 1 through two vertically arranged guide rails 7, and the end of the outlet pipe 4 far away from the suction pump 2 is set on the hanging pan. On the pan 6, the first electric hoist 8 fixed on the frame 1 is arranged above the suspension pan 6, the first electric hoist 8 is connected with the suspension pan 6 through a steel cable, and both sides of the suspension pan 6 are A roller 33 is provided, and the roller 33 is connected to the suspension plate 6 through the second bearing 34. The outlet pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com