Movable incinerator grate turning device

A kind of incinerator, mobile technology, applied in the field of mobile incinerator grate turning device, can solve the problems such as difficult to meet the standard and difficult to adopt, and achieve the effect of realizing stable incineration and meeting the needs of compactness and mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

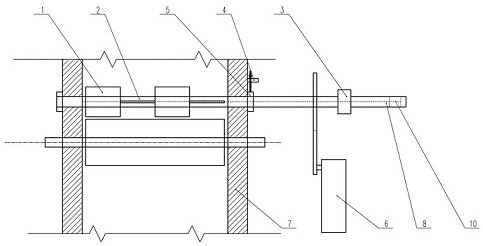

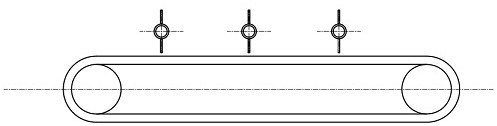

[0016] see Figure 1-Figure 2 , this embodiment provides a mobile incinerator grate turning device, which is respectively arranged at the front, middle and rear ends of the grate, the front turning device is set in the middle of the drying zone, and the rear turning device is set in the burnout zone 1 / 3 positions, including turning paddle 1, air-cooled hollow shaft 2, rotary joint 3, adjustment structure 4, high temperature resistant bearing 5, reducer 6, furnace wall 7, air supply and exhaust pipeline 8, secondary fan 9 And the air cooling structure 10, the air-cooled hollow shaft 2 is fixed on the furnace wall 7 through the adjustment structure 4 and the high temperature resistant bearing 5, the hollow shaft of the reducer 6 is connected with one end of the air-cooled hollow shaft 2, and the air-cooled hollow shaft 2 is located at A number of flippers 1 are evenly arranged on the shaft section between the furnace walls 7. The secondary fan 9 is connected to the end of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com