A process for making acid by combined incineration of waste sulfuric acid and hydrogen sulfide and the incinerator used

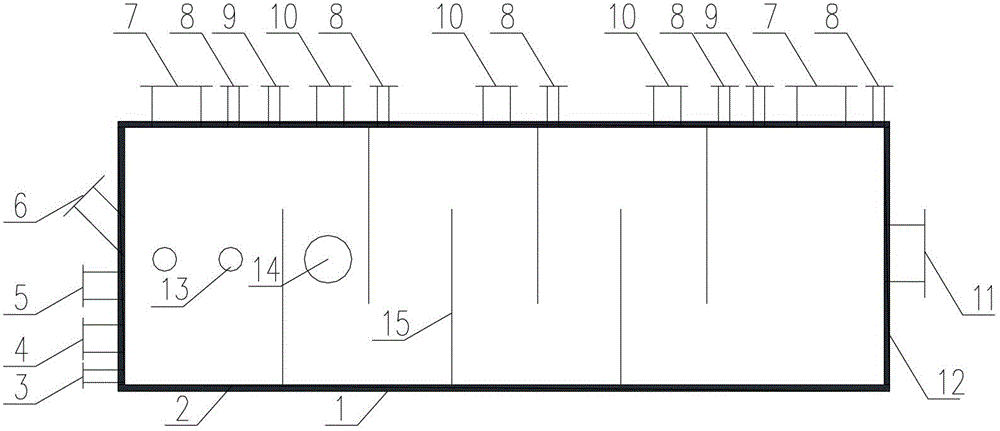

A technology of hydrogen sulfide and waste sulfuric acid, applied in the field of incinerators, can solve the problems of uneven mixing with hydrogen sulfide, uneven atomization of waste sulfuric acid, easy blockage of equipment, etc., and achieves thorough chemical reaction, reliable performance and good adaptability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A process for making acid by co-incinerating waste sulfuric acid and hydrogen sulfide, comprising the following steps:

[0027] Step (1): The waste sulfuric acid with a by-product concentration of 75% in the refinery is atomized by a combination of high-pressure pump mechanical atomization and compressed air assisted atomization to form acid mist, and the particle size of the acid mist is 20~80um;

[0028] Step (2): Mix hydrogen sulfide gas with a concentration of 30% by-product of the refinery and hot air in the swirl air inlet to make a mixed gas of hydrogen sulfide gas and hot air;

[0029] Step (3): The acid mist is sprayed into the incinerator with a waste acid spray gun, and at the same time, the mixed gas of hydrogen sulfide gas and hot air is sprayed into the incinerator with a hydrogen sulfide spray gun for incineration, cracking and reduction reaction to generate SO 2 furnace gas, the SO 2 The furnace gas enters the acid system after recovering heat from the...

Embodiment 2

[0032] A process for making acid by co-incinerating waste sulfuric acid and hydrogen sulfide, comprising the following steps:

[0033] Step (1): The waste sulfuric acid with a by-product concentration of 85% in the refinery is atomized by a combination of high-pressure pump mechanical atomization and compressed air assisted atomization to form acid mist. The particle size of the acid mist is 10~50um;

[0034] Step (2): Mix hydrogen sulfide gas with a concentration of 35% by-product of the refinery and hot air in the swirl air inlet to fully make a mixed gas of hydrogen sulfide gas and hot air;

[0035] Step (3): The acid mist is sprayed into the incinerator with a waste acid spray gun, and at the same time, the mixed gas of hydrogen sulfide gas and hot air is sprayed into the incinerator with a hydrogen sulfide spray gun for incineration, cracking and reduction reaction to generate SO 2 furnace gas, the SO 2 The furnace gas enters the acid system after recovering heat from t...

Embodiment 3

[0038] A process for making acid by co-incinerating waste sulfuric acid and hydrogen sulfide, comprising the following steps:

[0039] Step (1): 30kt / a waste sulfuric acid with a by-product concentration of 95% in the refinery is atomized by a combination of high-pressure pump transport mechanical atomization and compressed air assisted atomization to form acid mist. Fog particle size 15 ~ 60um;

[0040] Step (2): 2000Nm of hydrogen sulfide gas with a concentration of 20% by-product in the refinery 3 / h is fully mixed with hot air in the swirling air inlet to make a mixed gas of hydrogen sulfide gas and hot air; the hot air is the high-temperature furnace gas after the waste heat boiler, and the air at normal temperature and pressure is indirectly heat-exchanged to 450 through a heat exchanger ℃~600℃

[0041] Step (3): The acid mist is sprayed into the incinerator with a waste acid spray gun, and at the same time, the mixed gas of hydrogen sulfide gas and hot air is sprayed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com