Display card welding cooling device and method with intelligent reciprocating type moving function

A mobile function and cooling device technology, which is applied in the direction of household refrigeration devices, auxiliary devices, welding equipment, etc., can solve the problems of waste of resources, slow cooling speed, loud noise, etc., achieve cooling efficiency and toxic gas emission, and increase cooling speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

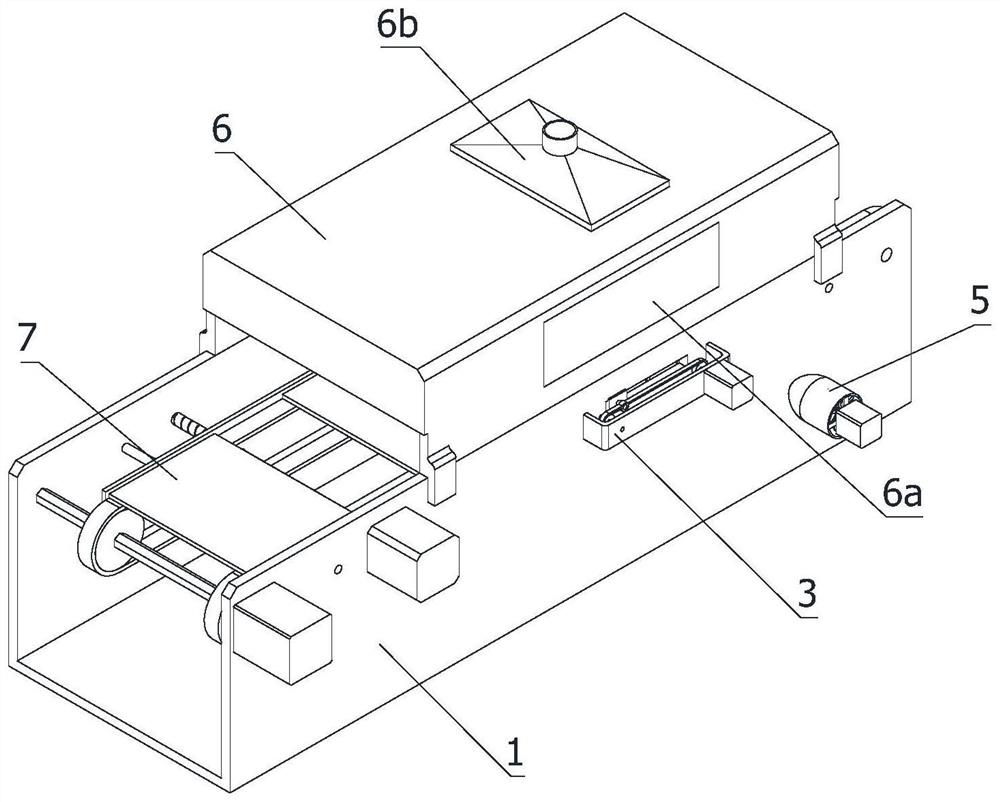

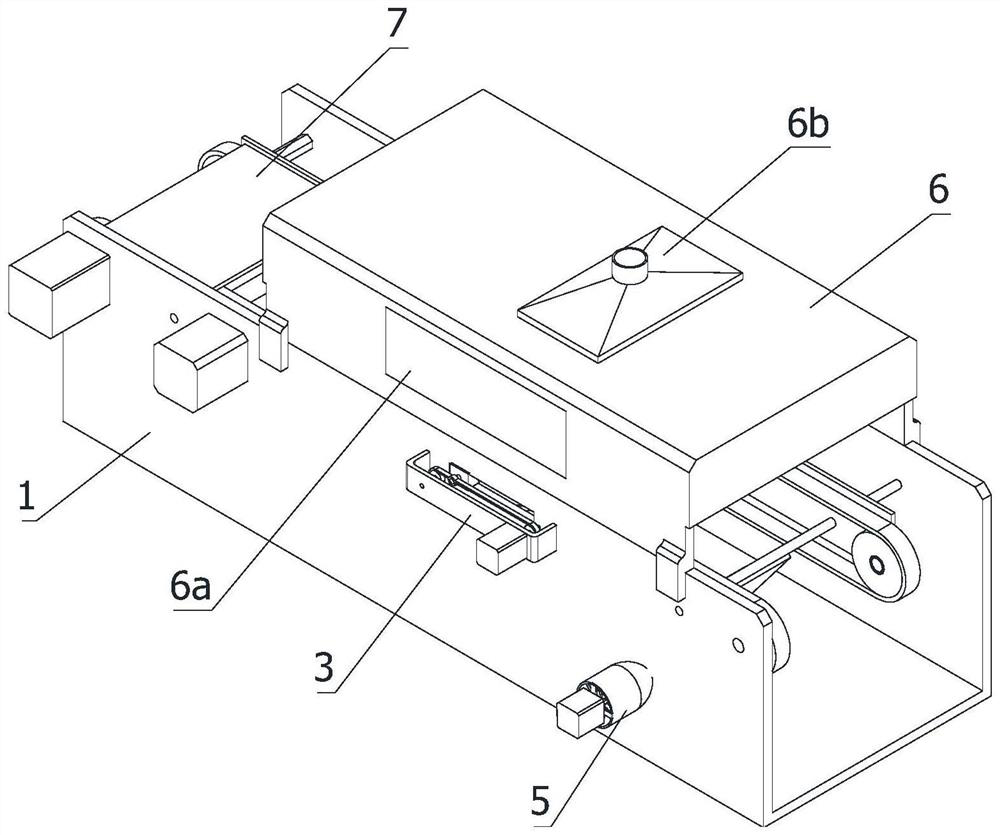

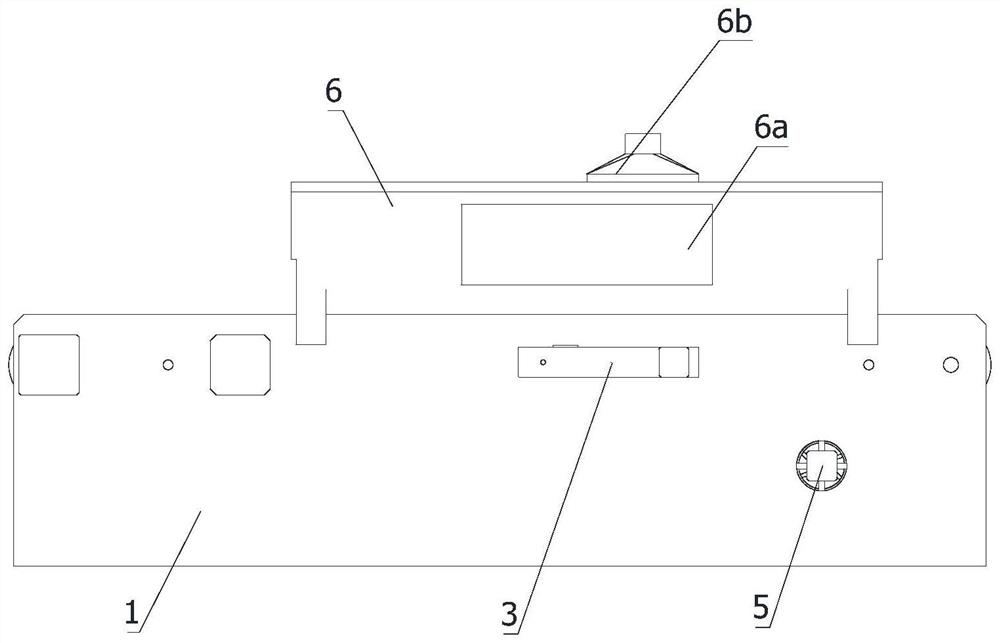

[0071] An implementation method of a graphics card welding cooling device with an intelligent reciprocating function, comprising the following steps:

[0072] Step 1. Place the graphics card PCB board on the output end of the material conveying mechanism 1, and the output end of the material conveying mechanism 1 drives the graphics card PCB board to move to the cooling area;

[0073] Step 2: When the graphics card PCB board touches the output end of the blocking component 2, the blocking component 2 sends a signal to the controller, and the controller suspends the work of the material conveying mechanism 1;

[0074] Step 3: The output end of the erecting mechanism 3 drives the roller 4a upward through the lifting rod 4, and the roller 4a rises along the hinge point of the lifting rod 4 and turns up the PCB board of the graphics card, and the PCB board of the graphics card is in a tilted state after being turned up;

[0075] Step 4, the output end of the air-cooling mechanism ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap