Nozzle mounting structure with a double-cooling type height sensor for laser processing head

A technology of height sensor and laser processing head, used in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problem that the cooling effect may not meet the cooling requirements, cannot guarantee the height sensor cutting and anti-slag, and affect the cutting production efficiency and other problems, to achieve the effect of ensuring the induction accuracy and the integrity of the appearance, reducing the temperature, and ensuring the processing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

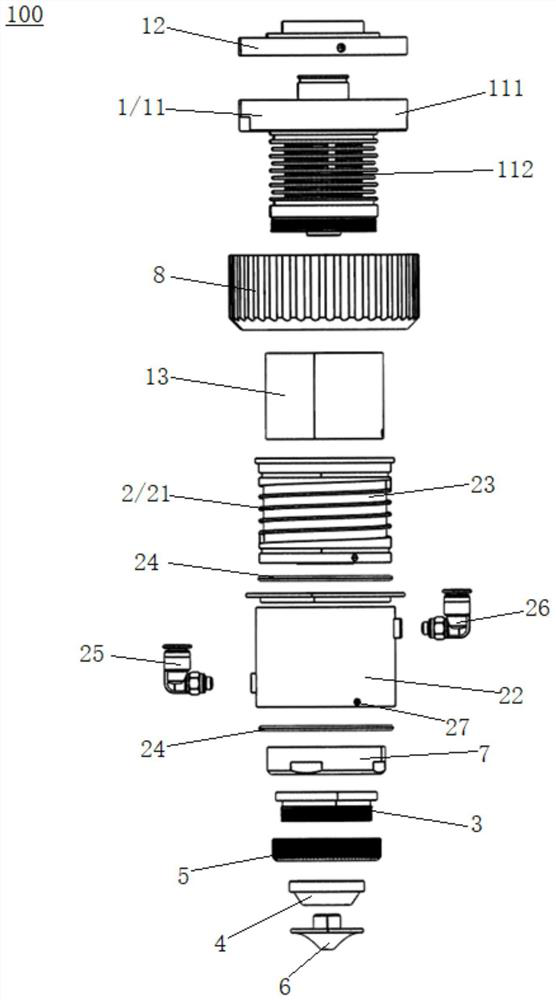

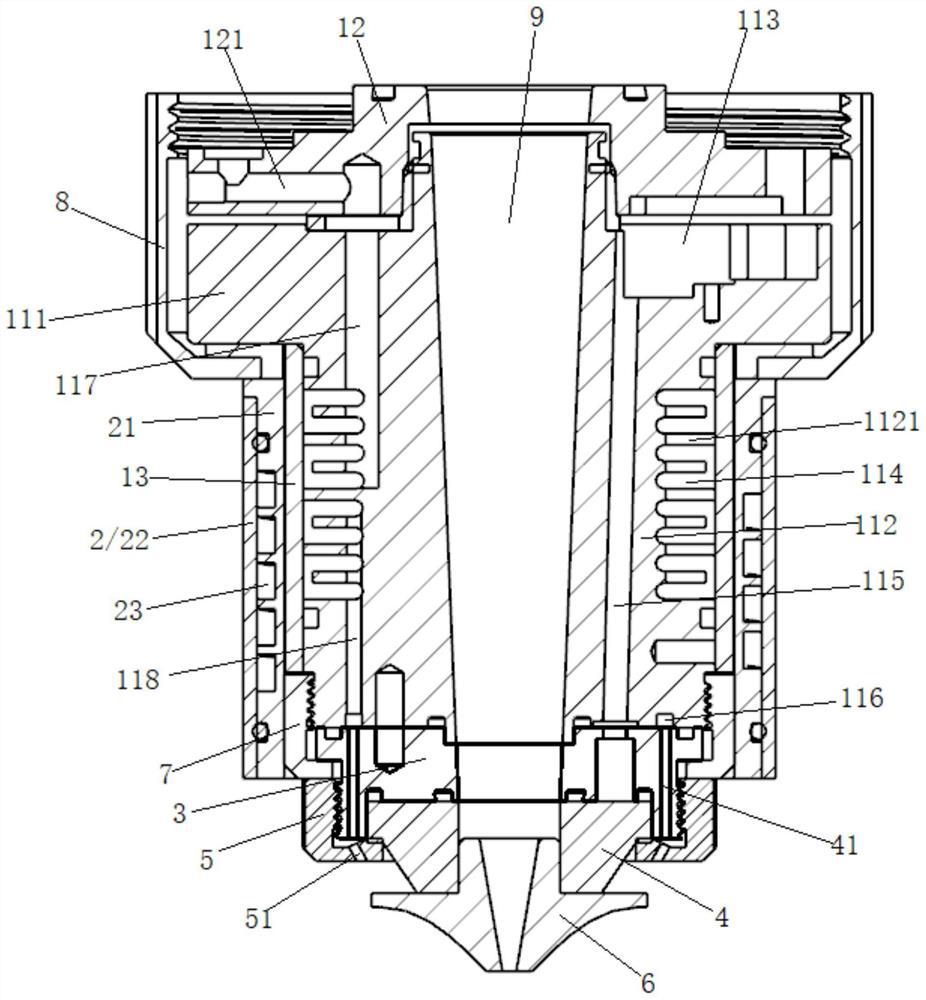

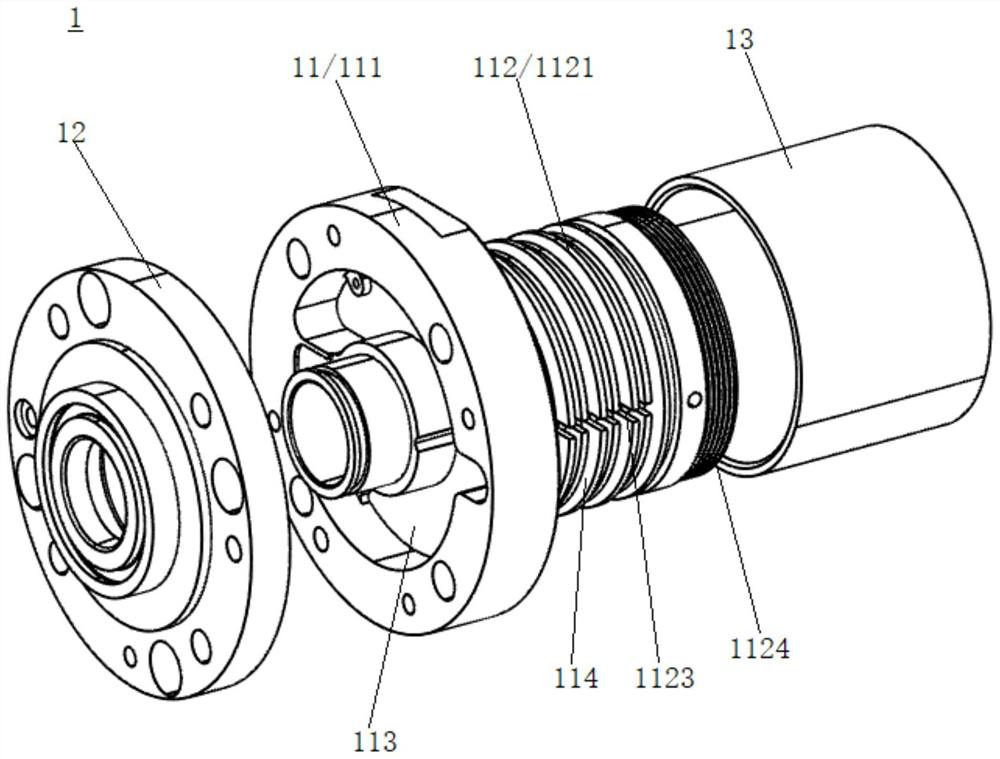

[0032] Please refer to Figure 1-Figure 8 , the present embodiment is a nozzle mounting structure 100 for a laser processing head with a double-cooled height sensor, which includes a cooling built-in height sensor 1, an outer cooling sleeve 2 that is sleeved outside the cooling built-in height sensor 1, and is arranged on the cooling The ceramic body mounting seat 3 at the bottom of the built-in height sensor 1, the mounting seat locking ring 7 that locks the ceramic body mounting seat 3 on the cooling built-in height sensor 1, and the nozzle mounting seat 4 installed on the ceramic body mounting seat 3 , the ceramic body locking ring 5 for locking the nozzle mounting seat 4 on the ceramic body mounting seat 3 , and the nozzle 6 installed on the nozzle mounting seat 4 .

[0033]The cooling built-in height sensor 1 , the ceramic mounting base 3 , the nozzle mounting base 4 and the nozzle 6 are vertically penetrated in the middle to form a laser channel 9 for the beam to pass th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap