Metal rolling device

A metal and refrigeration room technology, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve the problems of easy rust, corrosion and adhesion of residues on the surface of the workpiece, unsatisfactory cooling effect, affecting the quality of workpiece products, etc. Product performance and quality, guaranteeing dryness, and the effect of reducing heat exchange stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

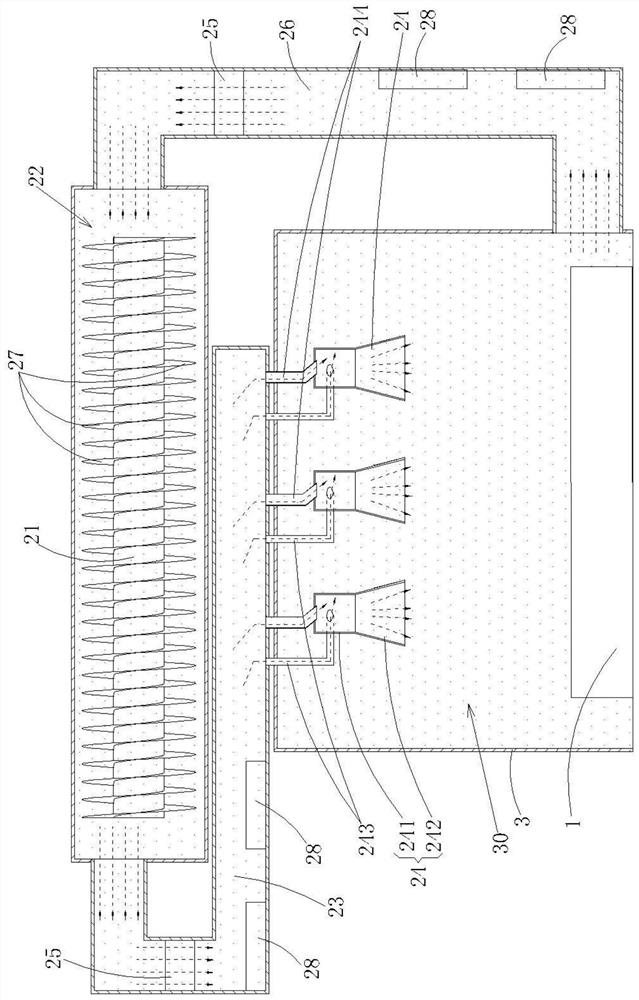

[0019] refer to figure 1 , the metal rolling device of the present embodiment comprises a rolling workbench 1, a cooling mechanism 2 and a protective cover 3 in a closed state; metal workpieces are rolled on the rolling workbench 1, and the inside of the protective cover 3 forms a cooling chamber 30 , the rolling table 1 is set in the cooling chamber 30 .

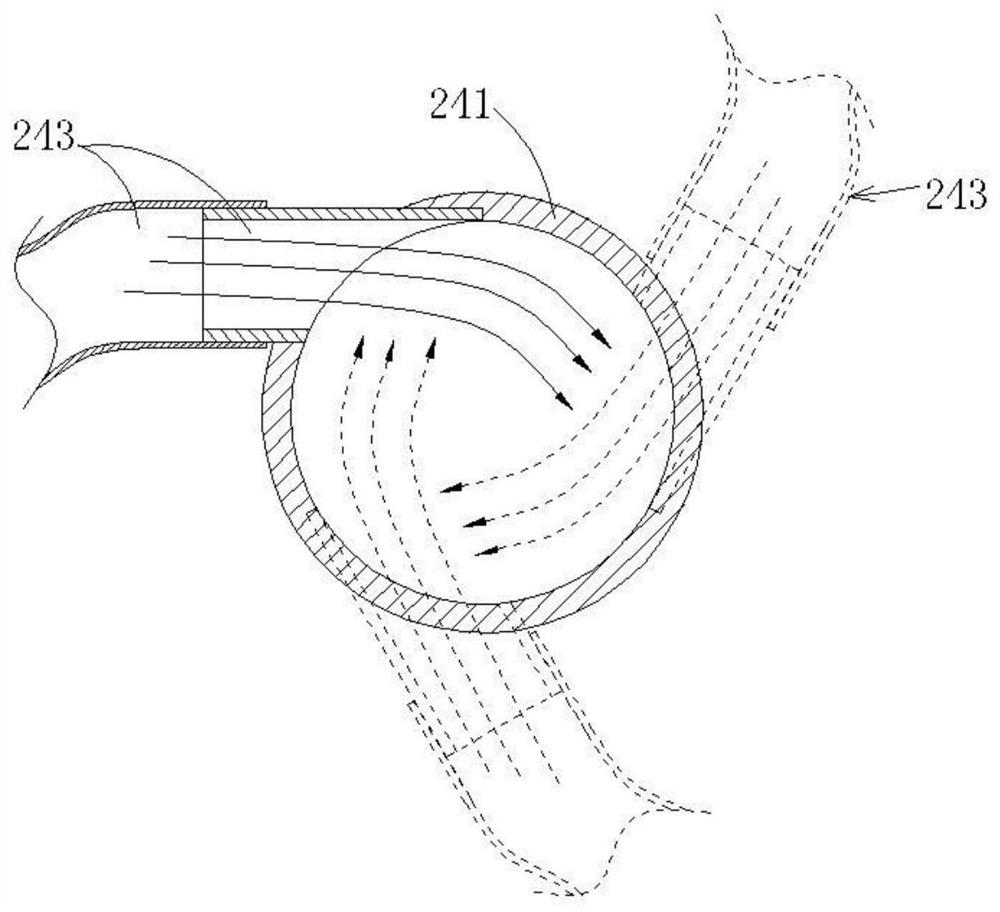

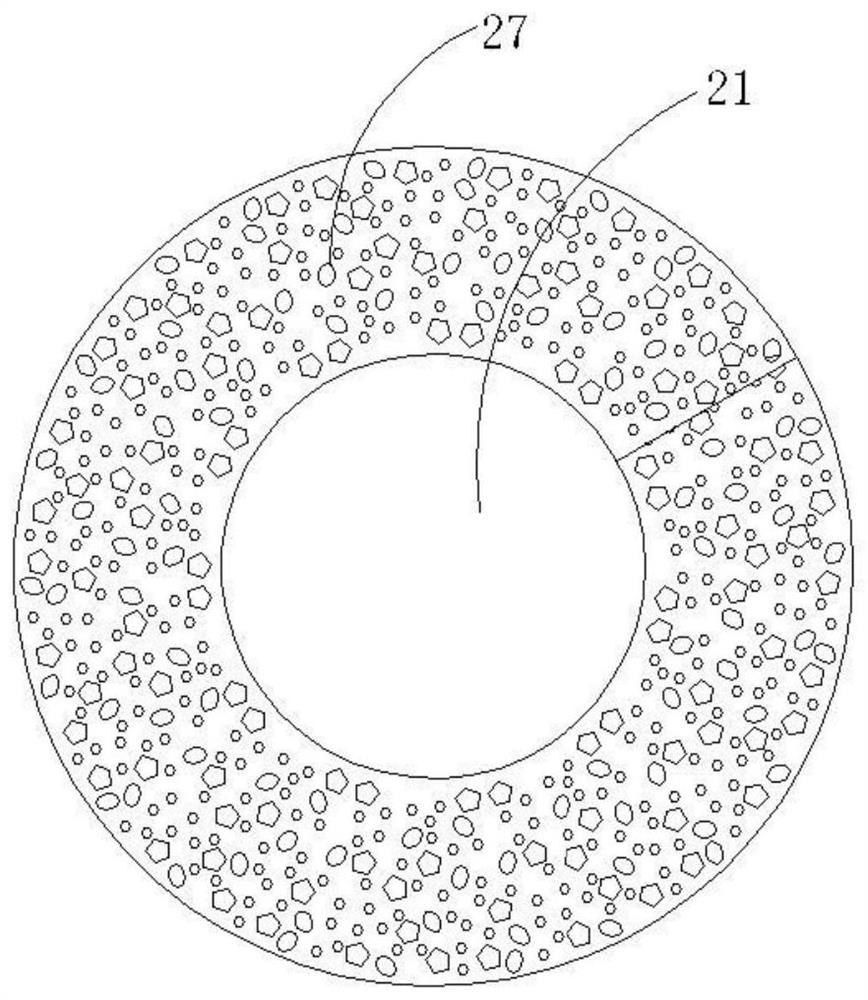

[0020] Continue to refer to figure 1 , the cooling mechanism 2 includes a refrigerator 21 , a refrigeration chamber 22 , an output pipeline 23 , a cold air nozzle 24 , a moisture absorber 28 , a blower 25 and a return pipeline 26 . Continue to refer to figure 1 , image 3 , Figure 4 , the refrigerator 21 is fixedly assembled in the refrigeration chamber 22, and the refrigerator 21 is used to cool the heat-absorbing gas flowing through the refrigeration chamber 22. The above-mentioned refrigerator...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap