Rapid pressing device based on 5G optical module PCB

A technology of a pressing device and an optical module, which is applied in the coupling of optical waveguides, manufacturing of multi-layer circuits, etc., can solve the problems of difficult discharge of trapped gas, poor processing, and easy internal gas trapping, so as to reduce the trapped gas problem and improve the pressure. Synthetic quality, effect of reducing gas trapping problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

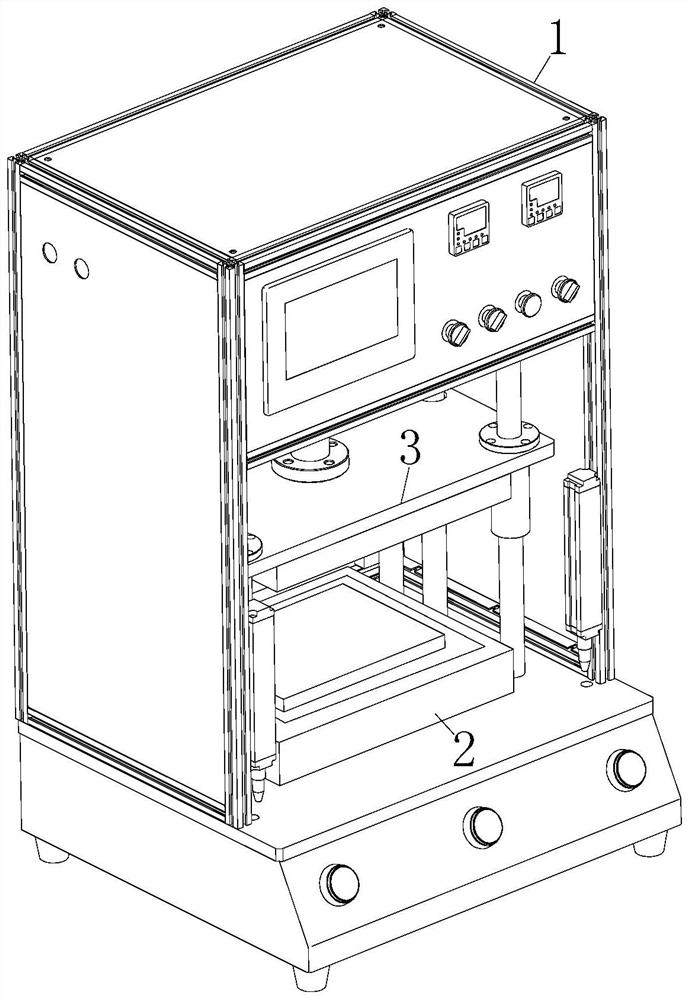

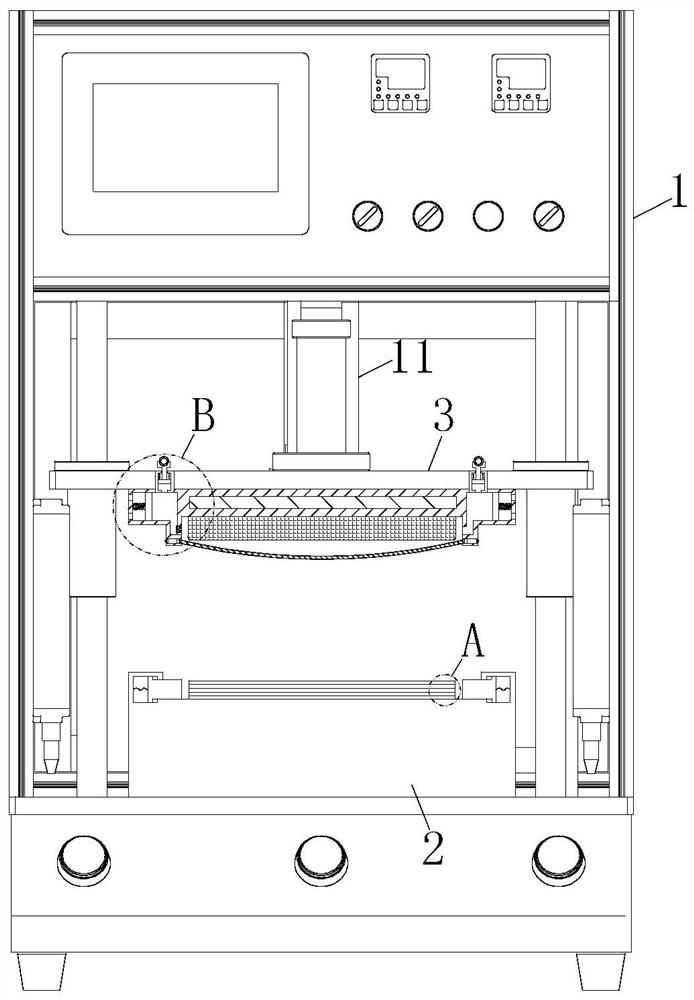

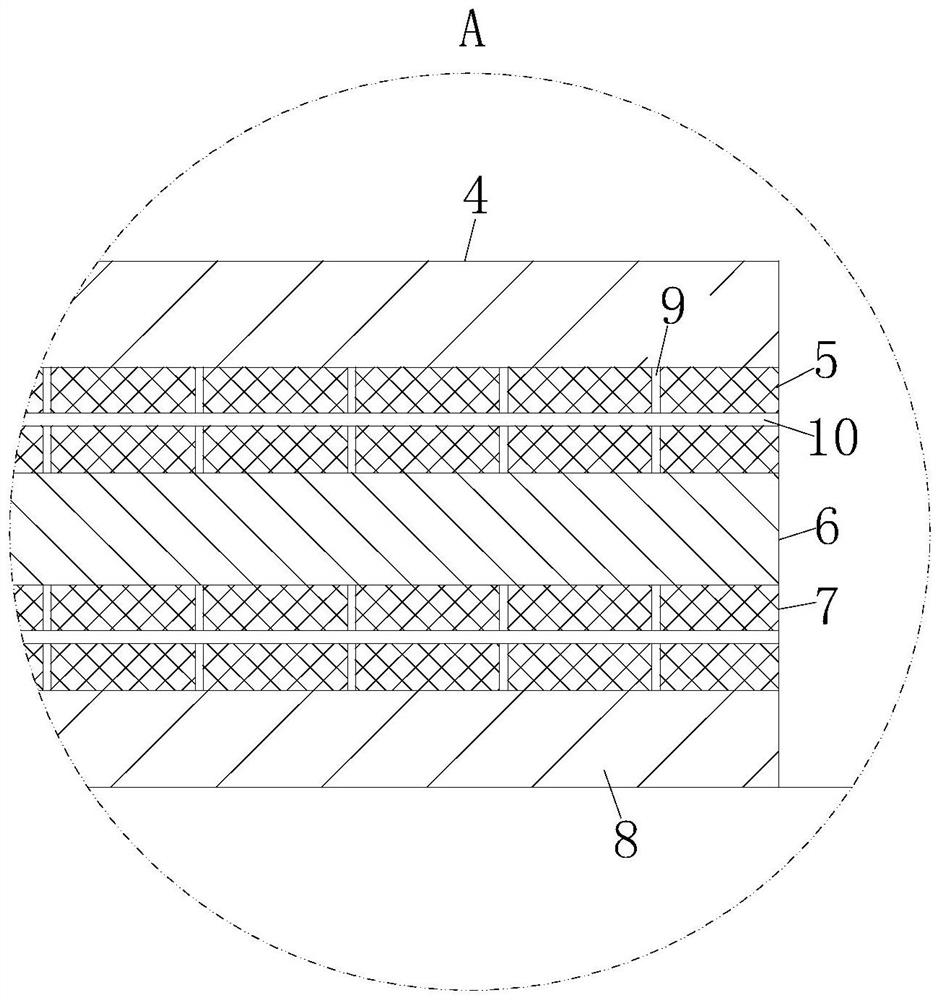

[0030] Such as Figure 1-Figure 3 As shown, a quick pressing device based on a 5G optical module PCB described in the embodiment of the present invention includes a body 1, a bottom plate 2 and a top plate 3; The top position of the bottom plate 2 is provided with the first copper foil 4, the first prepreg 5, the inner core board 6, the second prepreg 7 and the second copper foil 8 in turn; the first prepreg 5 and the second prepreg 7 The surface of the body 1 is provided with evenly arranged air guide holes 9; the inside of the first prepreg 5 and the second prepreg 7 are provided with an air guide channel 10; the inside of the body 1 is fixed with a telescopic rod near the top of the body 1 11; the bottom surface of the telescopic rod 11 is fixedly connected with a top plate 3; the inside of the top plate 3 is fixedly connected with a heating block 13; during work, the first prepreg 5 and the second prepreg 7 are provided with an air guide hole 9 and an air guide Channel 10...

Embodiment 2

[0038] Such as Image 6 As shown in Comparative Example 1, another embodiment of the present invention is: a combination piece 28 is fixedly connected to the inside of the connecting hole close to the position of the filter plate 20; the combination piece 28 includes two second elastic pieces 29 and two third elastic pieces 30; the two second elastic pieces 29 are designed in an S-shaped structure; the two third elastic pieces 30 are designed in a C-shaped structure; the two second elastic pieces 29 are combined together A one-way structure is formed; the second elastic piece 29 and the third elastic piece 30 are jointly combined to form a one-way structure; when working, by setting the second elastic piece 29 and the third elastic piece 30, the two second elastic pieces 29 are jointly formed One-way flow guide structure, at the same time, the second elastic piece 29 and the third elastic piece 30 will also form a reverse one-way flow guide structure, so that different positio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap