Medical efficient sterilization mask and manufacturing method thereof

A mask, high-efficiency technology, applied in the field of masks, can solve the problem of fast loss of filter elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

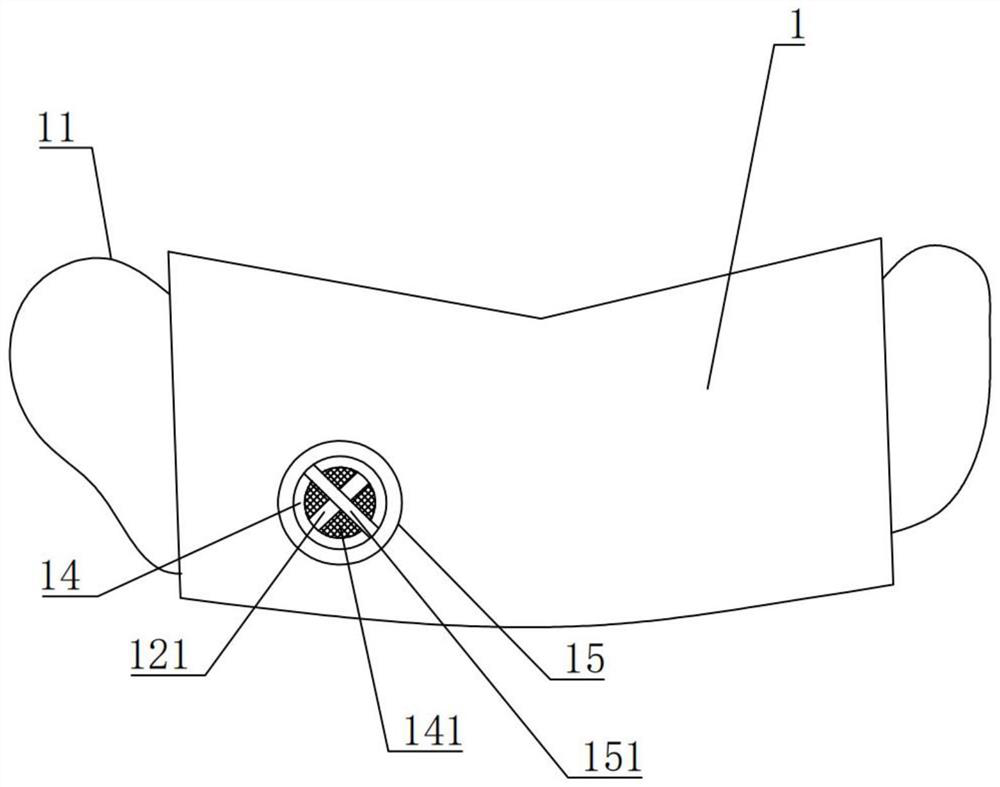

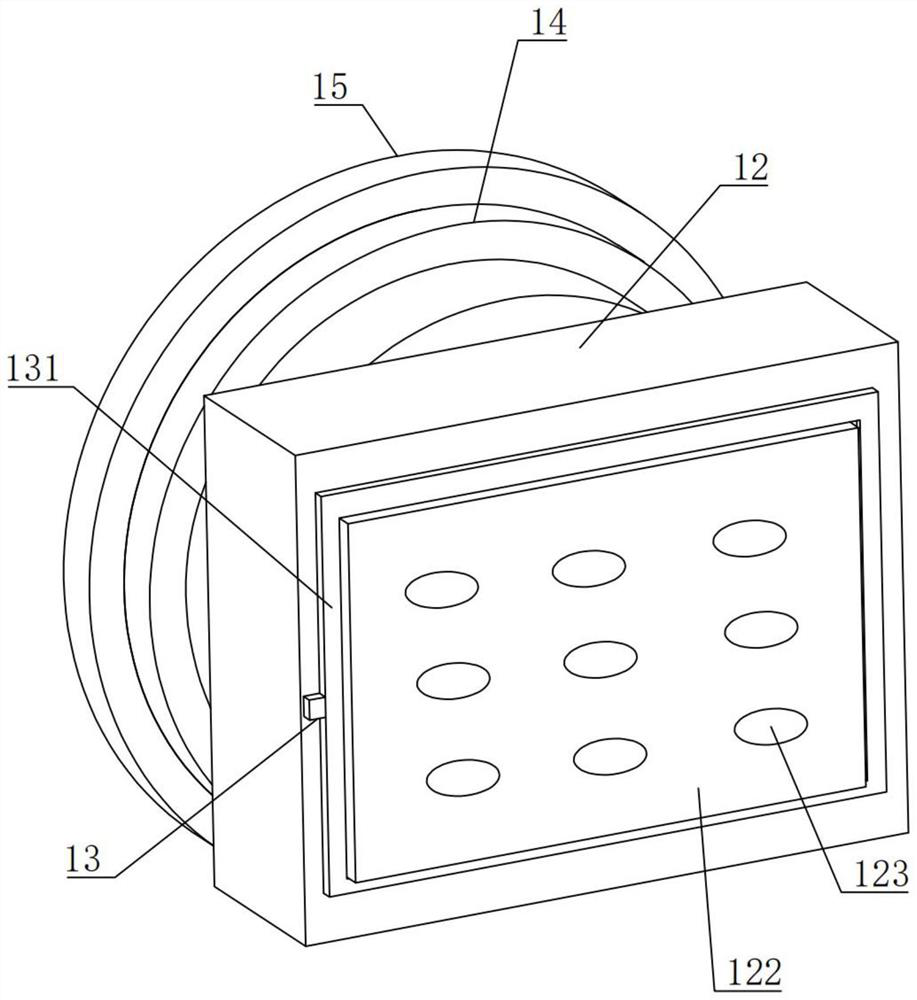

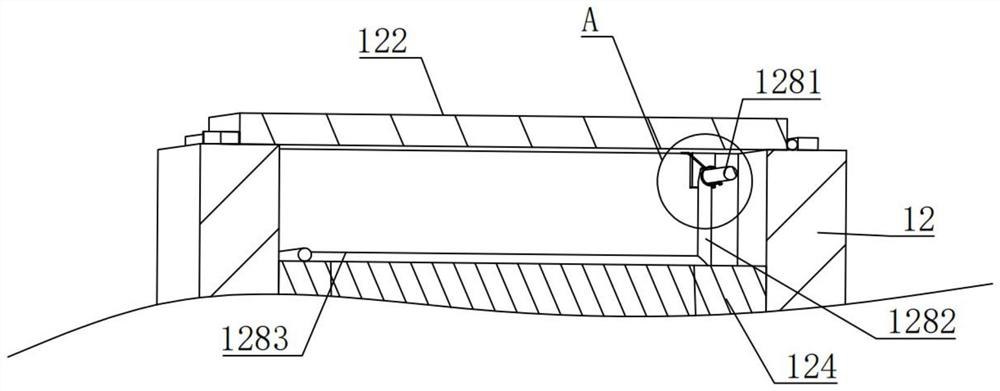

[0028] Embodiment one; A kind of medical high-efficiency sterilization mask, as figure 1 and figure 2 , comprising a mask body 1 and an annular lanyard 11 arranged at both ends of the mask body 1, the mask body 1 is provided with a ventilation pipe 12 communicating with the air on both sides of the mask body 1, the mask body 1 is a mask covering the size of the lower half of the face of a person, It only needs to be able to cover the lower half of the face of the person, and when it is brought to the face, it fits the face. Since the invention of the present invention lies in the replacement of the filter element, and the mask body 1 is a prior art, it will not be described in detail here. The air pipe 12 is provided with an air filter element. When the mask is brought to the face, the end of the air pipe 12 away from the face is provided with some stop rods 121 that restrict the removal of the air filter core from the air pipe 12, and the air pipe 12 is far away from the sto...

Embodiment 2

[0039] Embodiment 2: A manufacturing method of a medical high-efficiency sterilizing mask, the air filter element is put into the ventilation pipe 12, the position of the air filter element is limited by the first limiting member, and the position of the closing plate 122 is limited by the second limiting member, when When the air filter element needs to be replaced, the air filter element is taken out through the second stopper and the first stopper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com