High-temperature-resistant fire rescue robot for forest rescue

A rescue robot and high temperature resistant technology, applied in the field of forest firefighting and rescue, can solve the problems of inconvenient firefighting location firefighting work, inconvenient adjustment, and reduced efficiency of firefighting rescue robots, and achieve clear and real-time firefighting conditions, clear fire conditions, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

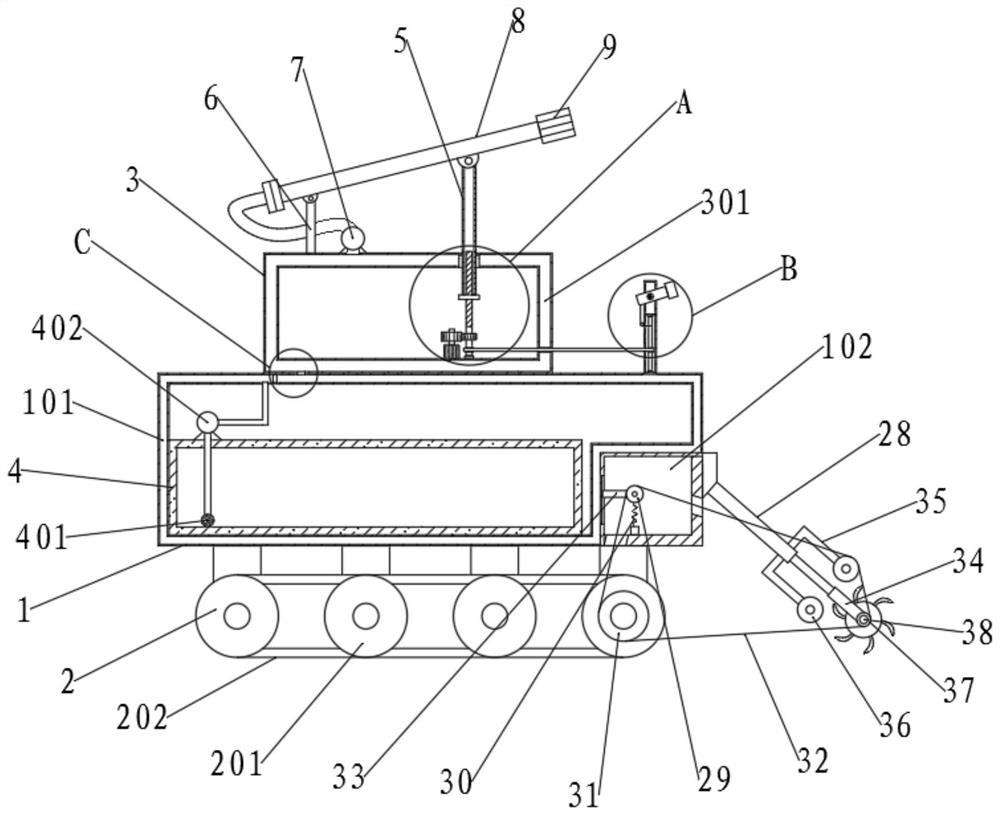

[0035] A high-temperature-resistant fire-fighting and rescue robot used for forest rescue, including a carrying case 1, a cooling mechanism is installed inside the carrying case 1, a water inlet chamber 101 is provided in the carrying case 1, and a working chamber is provided at the lower right side of the carrying case 1 102, the upper end is equipped with a working box 3;

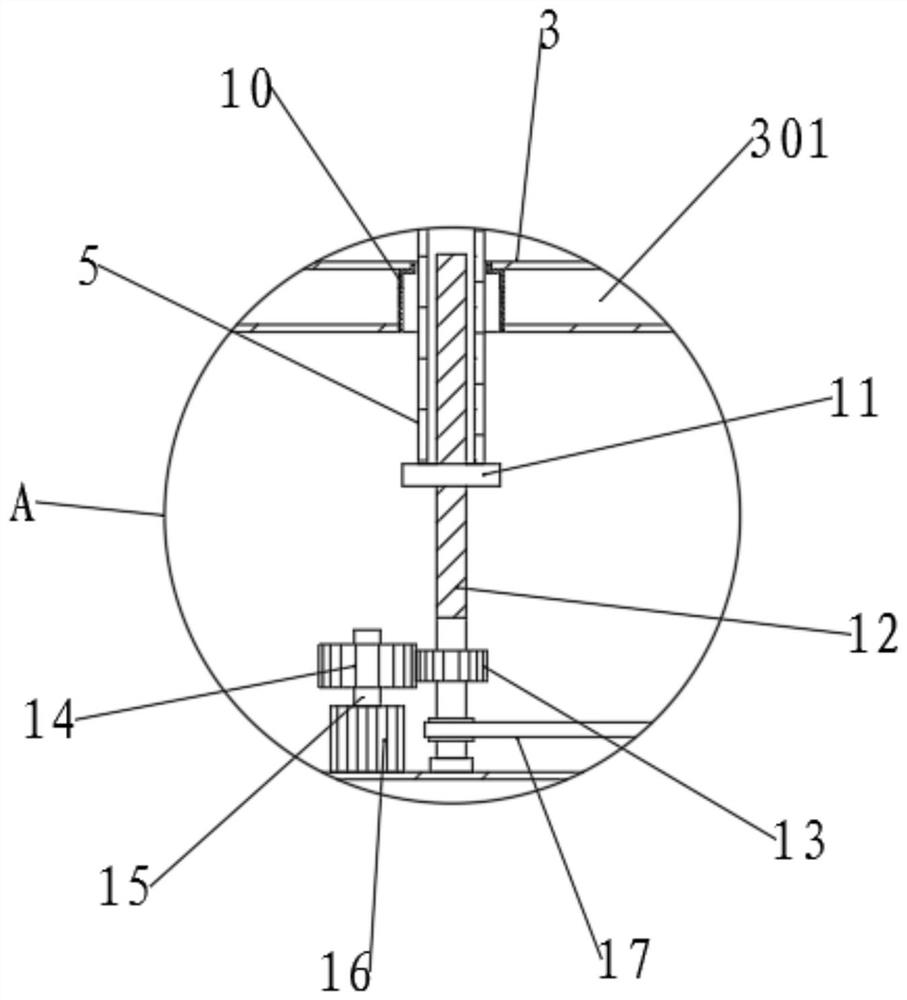

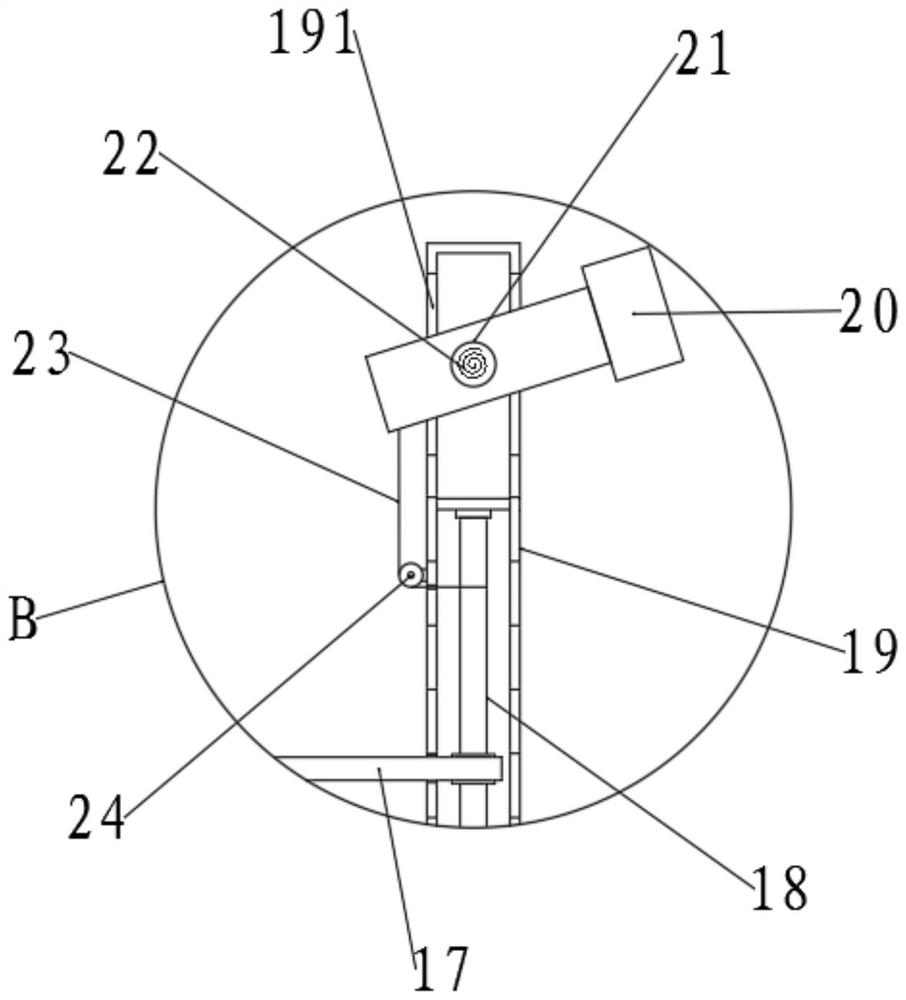

[0036] The working box 3 is provided with a water inlet chamber 301, and the water inlet chamber 301 is connected with the water inlet chamber 101 through the connecting pipe 104. An adjustable water spray mechanism is installed inside the work box 3, and the adjustable water spray mechanism is connected with the adjustable image acquisition assembly. connect;

[0037] A retractable obstacle breaking assembly is installed on the front side of the carrying case 1, and a chain tightness maintaining assembly is installed correspondingly in the working cavity 102 of the carrying case 1, and the chain tightnes...

Embodiment 2

[0049] The difference from Example 1 is:

[0050] The interior of the rotating shaft five 38 is hollow, and the internal rear end is equipped with a rotating motor 44, and the rotating shaft five 38 is symmetrically provided with strip holes 381 up and down. Rotationally connected, the rotating shaft 6 43 is provided with a threaded section and correspondingly screwed with more than 45 sliding sleeves 2, and the upper and lower ends of each sliding sleeve 45 are connected with the fixed connection seat 41, and the fixed connection seat 41 is respectively extended and matched with the corresponding strip. shaped hole 381, the fixed seat 41 is detachably fixedly connected with the No. 2 crushing knife 40 through the corresponding fixing bolt 42 respectively, which is convenient for adjusting the distance between the No. 2 crushing knife 40 and the No. 1 crushing knife 39, and can be used for different obstacles according to the situation. Do the cleanup.

[0051] Working method...

Embodiment 3

[0053] The difference from Example 2 is:

[0054] Camera installation sleeve 20 places are equipped with camera cleaning mechanism, and camera cleaning mechanism comprises rotating shaft 4 27, and rotating shaft 4 27 is rotationally connected on the camera installation sleeve 20, and is connected together with output motor, and the front end of rotating shaft 4 27 stretches out camera installation sleeve 20 , and correspondingly installed with the cleaning bristles 26 that cooperate with the camera 25, the output motor work drives the cleaning bristles 26 to rotate, which is convenient to clean the camera 25 mirrors with dust or stains on the surface.

[0055] Working mode: on the basis of the steps in combination with embodiment 1 and embodiment 2, a camera cleaning mechanism is installed at the camera 25, and by controlling the output motor to work, the rotating shaft 27 and the cleaning bristles 26 are driven to rotate, and the cleaning bristles 26 rotate and can Cleaning t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com