Rotary hot pressing equipment with automatic conveying function

A technology of automatic conveying and hot-pressing equipment, which is applied in the field of PCB board welding, can solve the problems of affecting product hot-pressing quality, reducing hot-pressing processing quality, and low hot-pressing processing efficiency, so as to improve product quality, reduce labor burden, and improve The effect of hot pressing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

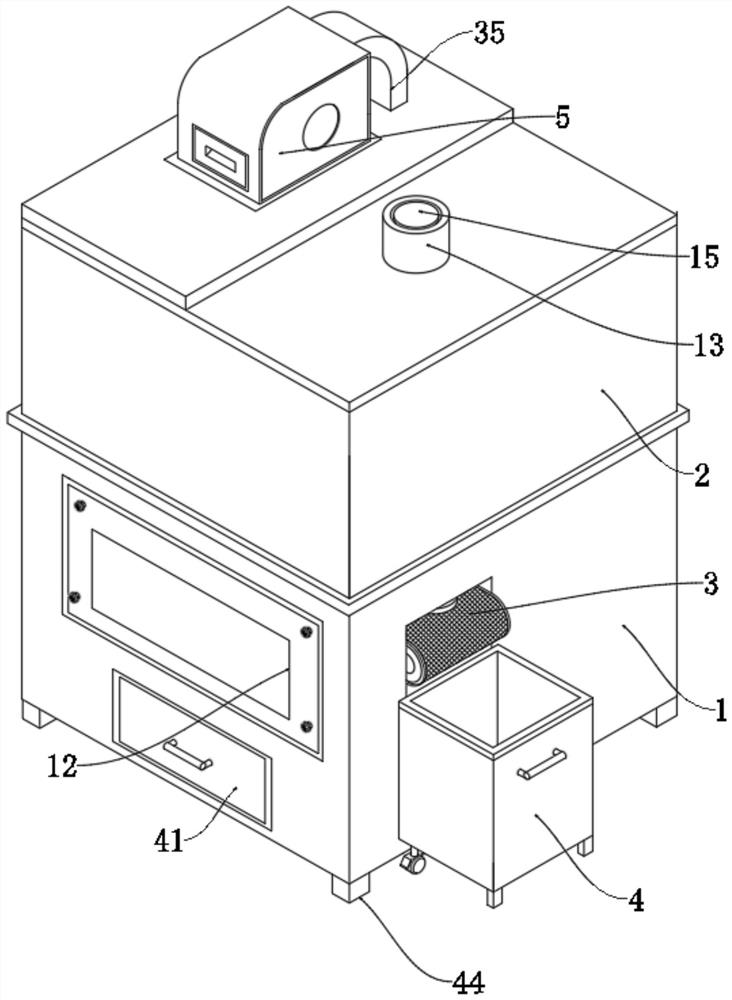

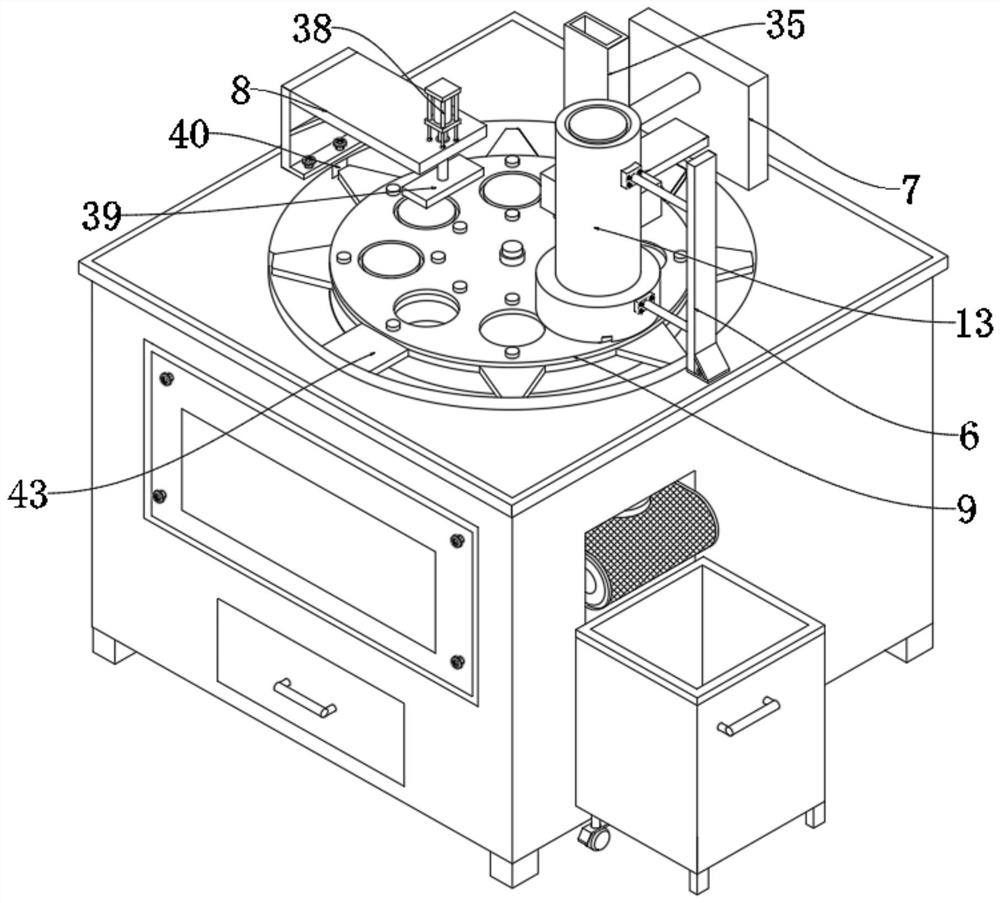

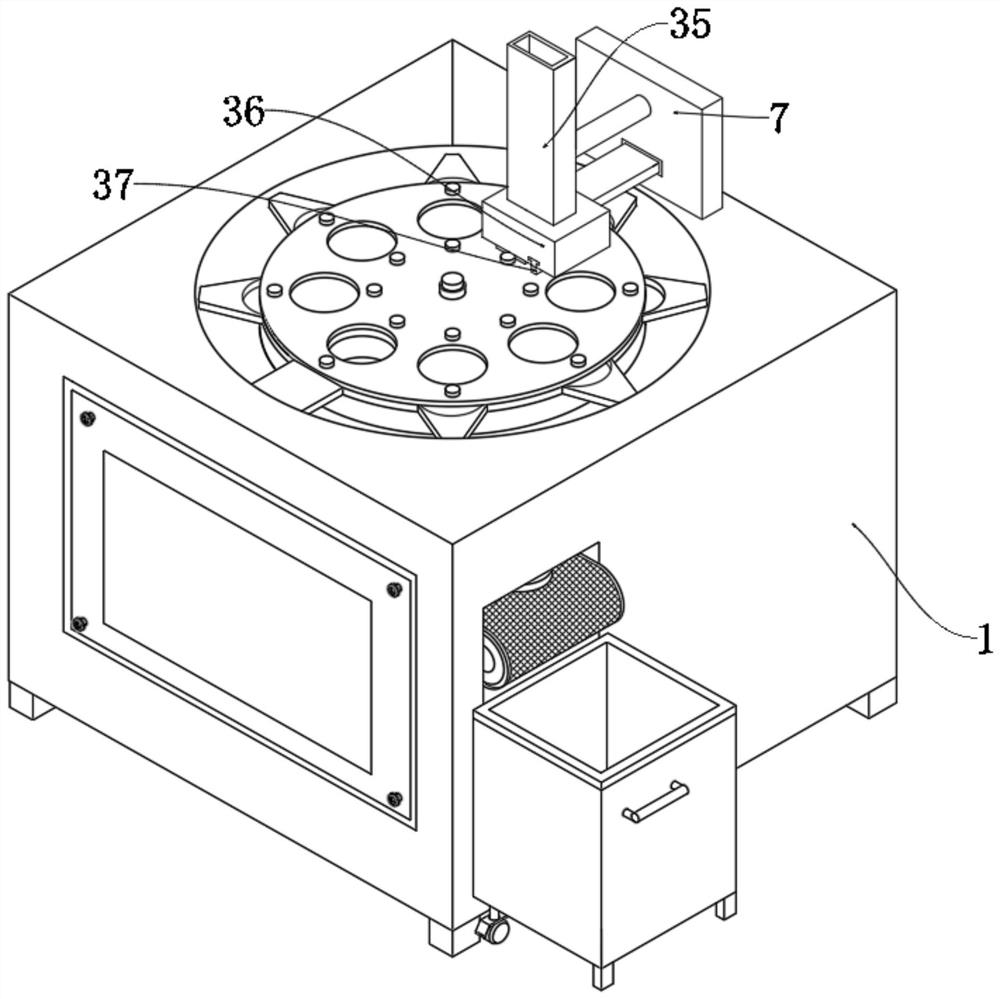

[0031] The present invention provides such as Figure 1-5 The rotary hot pressing equipment with automatic conveying function shown includes a hot pressing machine body 1, a fixed cover body 2, a transmission mechanism 3, a collection box 4, a dust collection device 5, a feeding mechanism 6, a dust removal rack 7 and a hot pressing machine. Fixed frame 8, one side of unloading mechanism 6 is fixedly connected with unloading tube 13, and the inner wall of unloading tube 13 is placed with hot-pressing parts 15, and the quantity of hot-pressing parts 15 is set to a plurality of, and the inner side of hot-pressing machine body 1 rotates Connected with the rotating disk 9, the bottom of the feeding pipe 13 is fixedly connected with the feeding seat 14...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap