Inner ring bending machine

A technology of bending circles and racks, which is applied in the direction of feeding devices, manufacturing tools, and ejection equipment, etc. It can solve the problems of low production efficiency, frequent mold opening and closing, and achieve high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

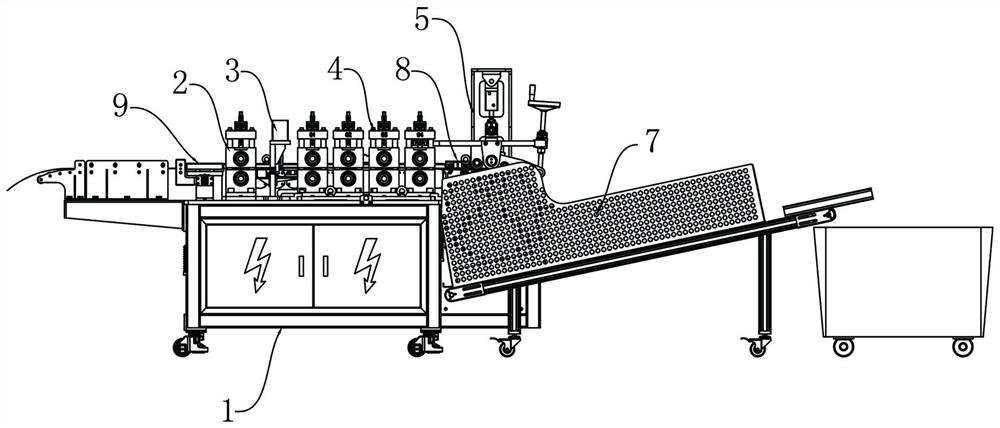

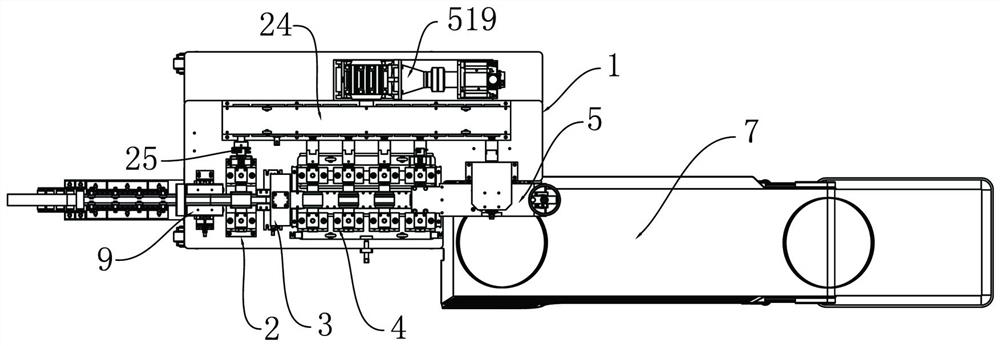

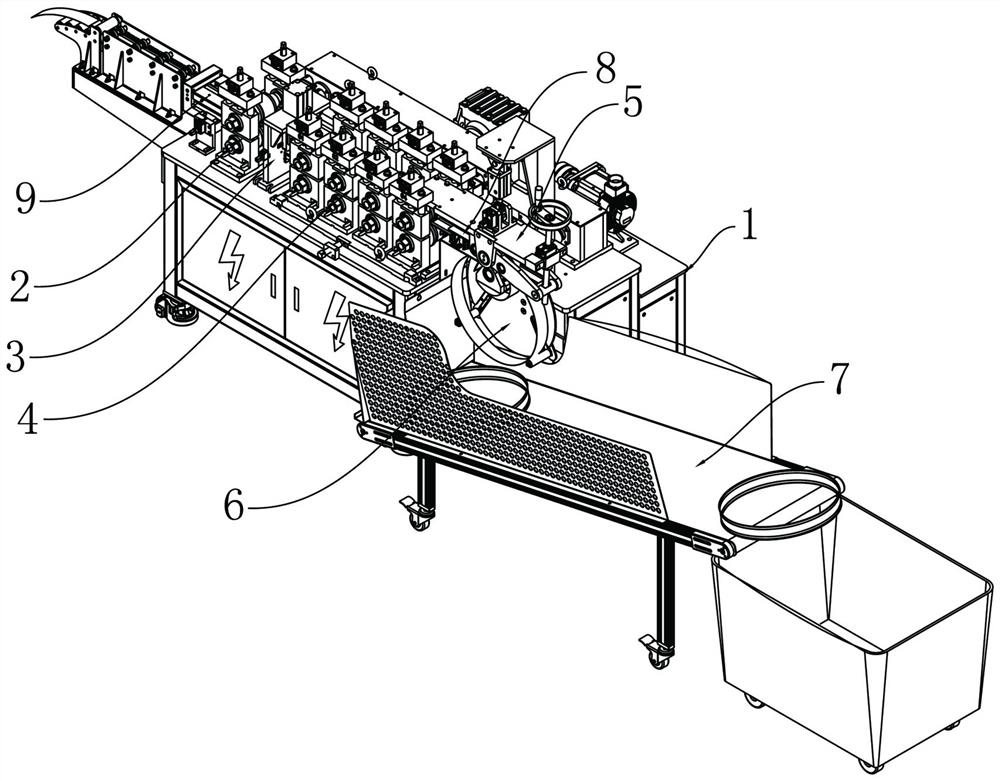

[0041] Such as figure 1 , figure 2 , image 3 As shown, the described inner ring bending machine includes: a frame 1, in which a conveying device 2 for conveying the belt is sequentially arranged along the conveying direction of the belt, for cutting the belt The cutting device 3, the rolling device for cold-forming the cut strips, the bending device for bending the cold-formed strips into rings 5, and the bending device for pushing the rings out The pushing device 6 of 5, and the storage device 7 used to collect the rings pushed out by the pushing device 6, the rolling device includes a number of rollers that are distributed successively along the conveying direction of the belt and can roll the belt. formed rolling mechanism 41, each rolling mechanism 41 includes a rolling upper roller 42 and a rolling lower roller 43 that can roll and form the belt in a vertically opposite shape. The difference between each rolling mechanism 41 is only Because the cross-sectional shapes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com