Continuous extruding process of Zn-Al-Ti alloy tube

A zn-al-ti and alloy technology, applied in the field of metal materials and forming, can solve problems such as poor welding, high deformation resistance of zinc alloy, poor weldability, etc., achieve uniform deformation, improve welding performance, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

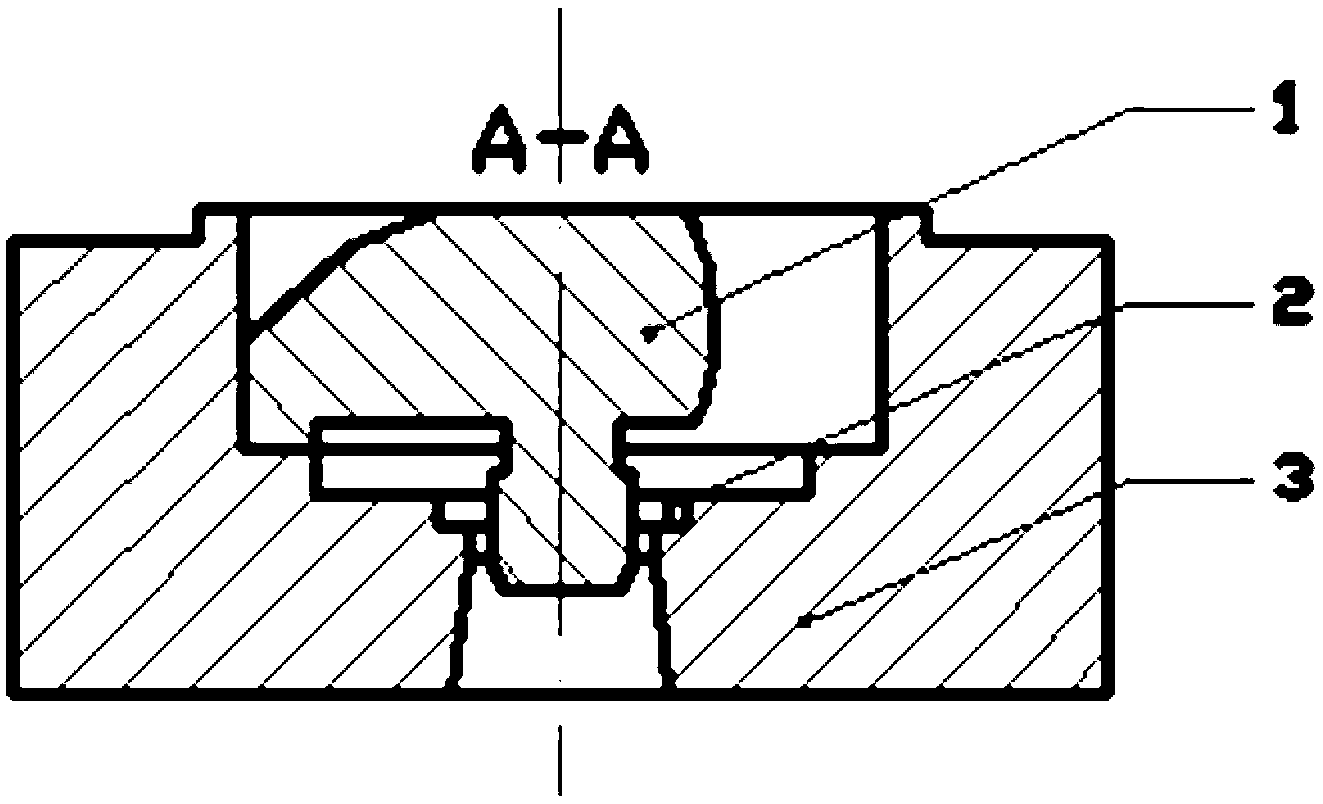

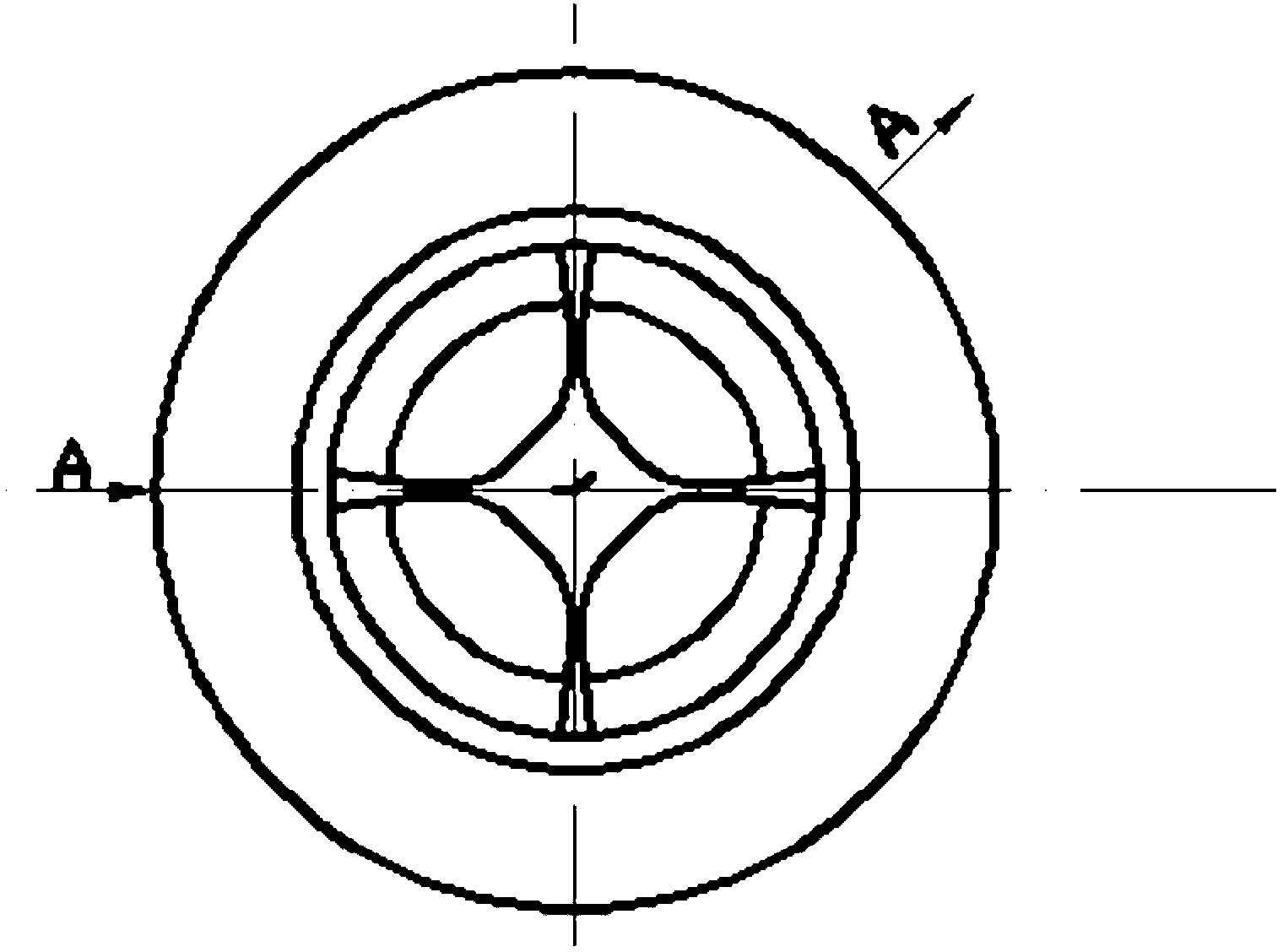

[0039] A continuous extrusion process for Zn-Al-Ti alloy pipes, the steps are as follows:

[0040] The first step: batching, melting and casting

[0041] According to the designed Zn-Al-Ti alloy composition ratio, the raw materials such as zinc, aluminum, copper, magnesium, titanium, chromium and pure cerium are melted in the melting furnace according to the following weight percentages: Al12%; Cu0.5%; Ti0 .05%; Mg0.2%, Cr0.15%; Cerium 0.25%; the rest is zinc and unavoidable impurities (impurity content ≤ 0.15%). Horizontal continuous casting into a Zn-Al-Ti alloy round billet with a diameter of 9mm;

[0042] The second step: cleaning and drying the blank surface

[0043] Clean the surface of the Zn-Al-Ti alloy round billet prepared in the first step, using 10-20% HNO3 or HCl aqueous solution, the solution temperature is 20-40°C, the washing time is 5-10min, and then in 20 After rinsing in clean water at ~40°C for 1-10 minutes, dry naturally;

[0044] The third step: Confo...

Embodiment 2

[0050] Carry out the continuous extrusion process of Zn-Al-Ti alloy pipe material according to embodiment 1, its step is as follows:

[0051] The raw materials such as zinc, aluminum, copper, magnesium, titanium, chromium and pure cerium are melted in the melting furnace according to the following weight percentages: Al12%; Cu0.5%; Ti0.05%; Mg0.2%, Cr0.15% ; cerium 0.25%; the rest is zinc and unavoidable impurities (impurity content ≤ 0.15%), horizontal continuous casting into a Zn-Al-Ti alloy round billet with a diameter of 10.5mm; A Zn-Al-Ti alloy round rod with a diameter of 12mm is extruded in a rotary continuous extrusion machine, the extrusion wheel speed is 10 rpm, and the temperature of the zinc rod at the extrusion exit is about 260°C; the extruded The round bar is sent to the continuous extrusion machine for secondary extrusion, the contact length between the extrusion wheel surface and the arc surface of the groove sealing block is controlled to 220mm-300mm, and the...

Embodiment 3

[0058] The raw materials such as zinc, aluminum, copper, magnesium, titanium, chromium and rare earth are melted in the melting furnace according to the following weight percentages: Al10%; Cu3.0%; Ti0.5%; Mg0.02%, Cr0.03%; Rare earth 0.15%; the rest is zinc and unavoidable impurities (impurity content ≤ 0.15%), horizontal continuous casting into a Zn-Al-Ti alloy round billet with a diameter of 11mm; the surface is cleaned and dried and then sent to the rotary A Zn-Al-Ti alloy round rod with a diameter of 13.5mm is extruded in a continuous extrusion machine, the extrusion wheel speed is 12 rpm, and the temperature of the zinc rod at the extrusion exit is about 280°C; the extruded round The rod is sent to the continuous extrusion machine for secondary extrusion, the contact length between the extrusion wheel surface and the arc surface of the groove sealing block is controlled to 220mm~300mm, and the running gap is less than 0.3mm, so that the deformed zinc alloy billet and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com