Flexible electric power cable with steel-tape corrugated longitudinal wrapping armor layer

An armored layer, flexible cable technology, applied in the field of power cables, can solve the problems of pollution, resources, management waste, low production efficiency, etc., and achieve the effects of solving environmental pollution problems, improving lateral compressive strength, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

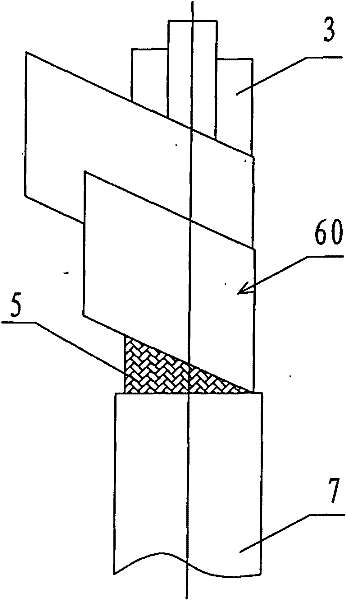

[0031] Such as figure 1 , is a structural schematic diagram of an existing flexible power cable wrapped with double-layer steel strips. Its wrapping type steel tape armor layer 60 is made by wrapping two superimposed and laminated steel strips. The main disadvantage is that after wrapping, the hardness is relatively high, it is difficult to bend, and the production efficiency is low.

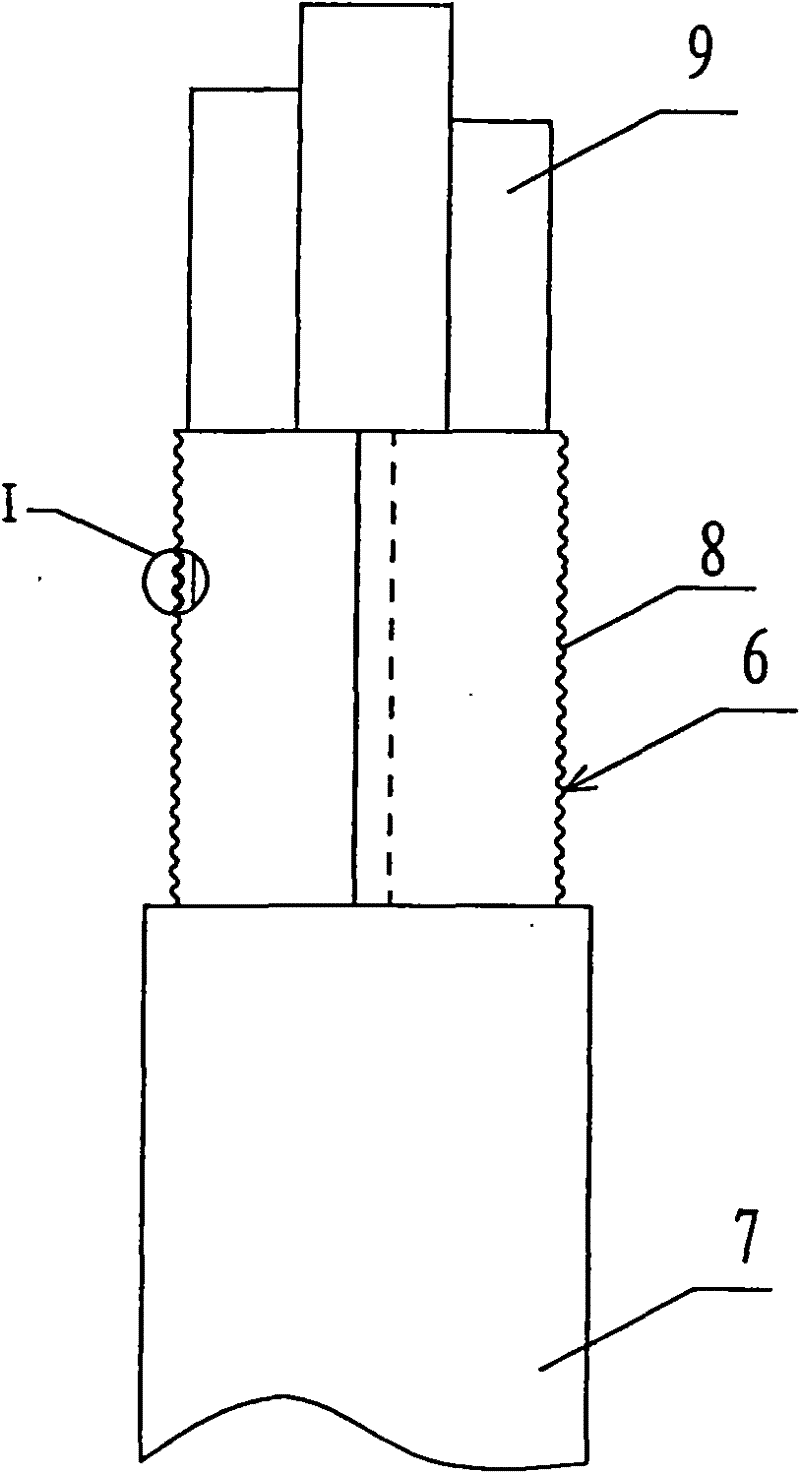

[0032] The steel strip longitudinally clad armor layer 6 of the power flexible cable with the steel strip longitudinally clad armor layer is made by two single-layer composite steel strips after corrugated longitudinally clad, and combined with the electric flexible The insulated core 11 inside the cable is extruded together with the sheath layer.

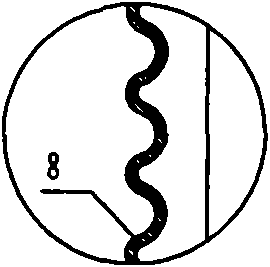

[0033] combine figure 2 , image 3 , Figure 4 , a flexible power cable with a steel strip corrugated longitudinally w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com