Transmission, drive unit and method for operating drive unit of vehicle

A technology of transmission and drive unit, applied in the field of vehicles, which can solve the problems of chain moving to another sprocket, restrictions on the use of transmissions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

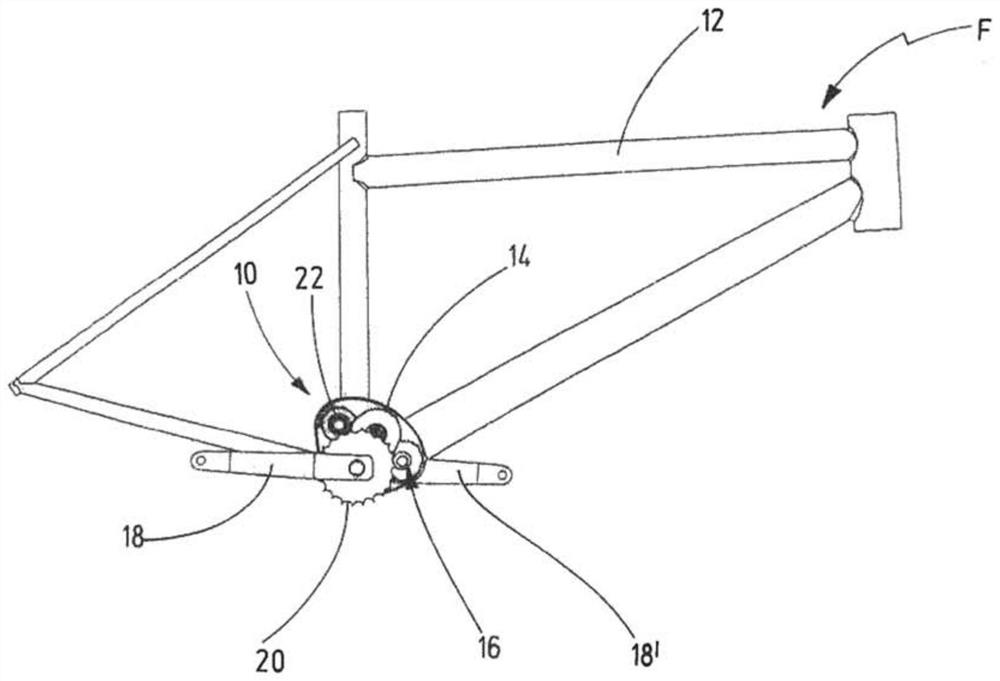

[0117] figure 1 is a schematic diagram of a drive unit 10 for a vehicle such as a bicycle F. FIG. The drive unit 10 is integrated in the bicycle frame 12 in the region of the bottom bracket. In this case, the drive unit 10 can be integrated in the bicycle frame 12 in such a way that the drive unit 10 forms a bottom bracket.

[0118] The drive unit 10 has a housing 14 connected at its outer periphery to a seat tube and a down tube (main pipe) of the bicycle frame 12 .

[0119] In the housing 14 is accommodated a transmission 16 configured to convert the drive motion introduced into the transmission 16 via the crank 18 into chain rings or pulleys having a number of different suitable transmission or gear ratios 20 spins.

[0120] Also accommodated in the housing 14 is an electric motor 22 which can supply additional drive power to the transmission.

[0121] Bicycle F is thus configured as an electric bicycle or pedelec. Preferably, the electric motor 22 can only be controll...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap