Direct-current high-voltage relay and contact material for direct-current high-voltage relay

A DC high voltage, contact material technology, applied in the direction of relays, electromagnetic relays, electromagnetic relay details, etc., to achieve the effect of excellent heat resistance, good arc discharge characteristics, and reliable on/off control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

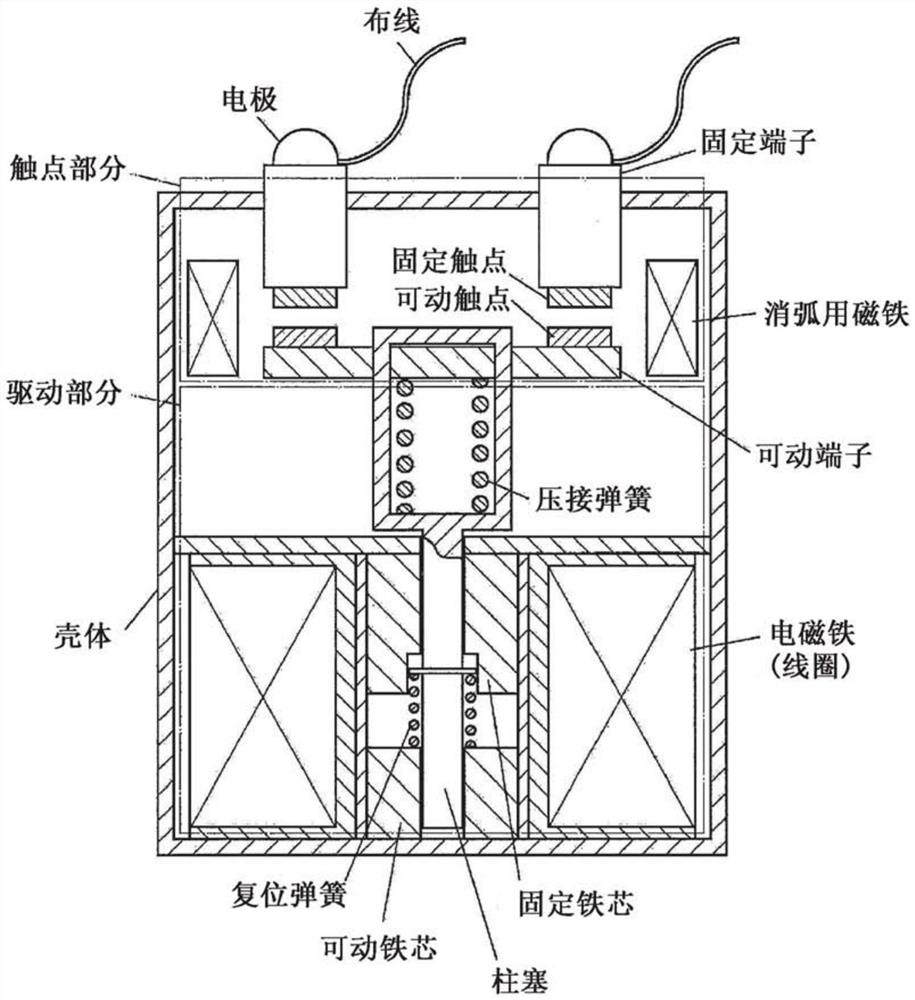

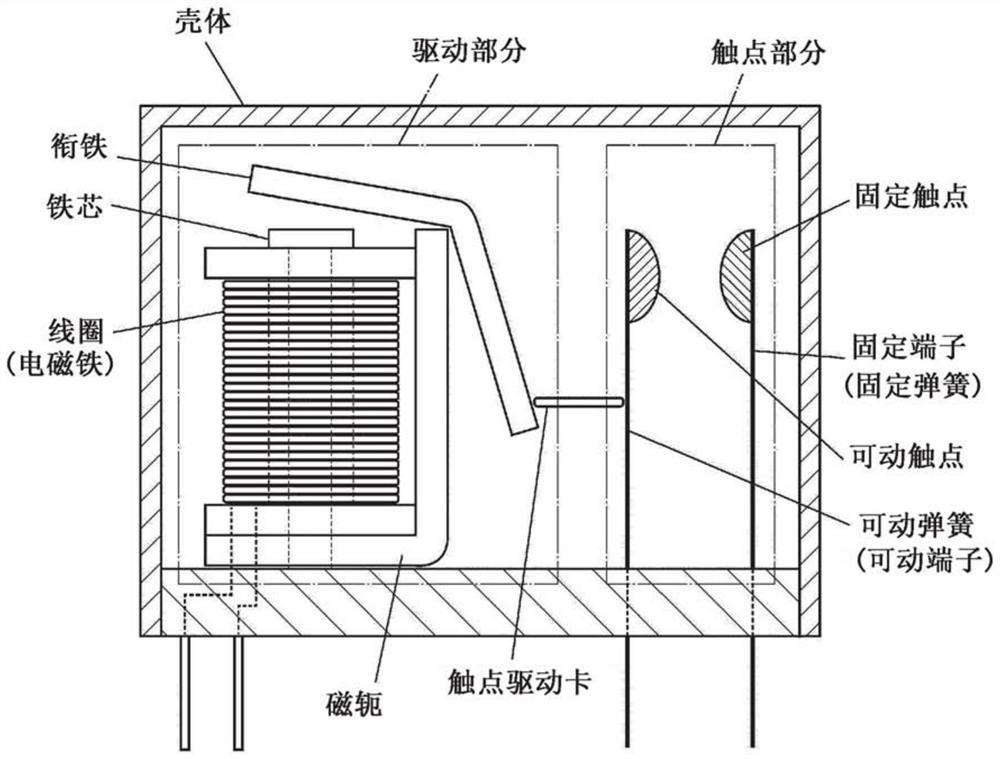

[0105] first embodiment : In this embodiment, various Ag-oxide contact materials are manufactured by internal oxidation method and powder metallurgy method, and the material characteristics are studied, and a DC high voltage relay (contact force / separation force: 75gf / 125gf) is manufactured, Operation confirmation (opening durability) was performed, and arc discharge characteristics and contact resistance were measured.

[0106] In the manufacture of a contact material by the internal oxidation method, first, an ingot of an Ag alloy of each composition is cast by melting and casting in a high-frequency melting furnace. After melting and casting, the ingot is made into a solid piece of less than 3mm, which is subjected to internal oxidation treatment. The internal oxidation treatment is to adjust the oxygen partial pressure and heating temperature within the range of oxygen partial pressure 0.2-0.9MPa and heating temperature 500°C-900°C. Next, collect the solid pieces after ...

no. 2 Embodiment approach

[0144] 2nd embodiment : In the present embodiment, the same DC high-voltage relay as the first embodiment is manufactured and the magnetic force of the arc-extinguishing magnet is set to be low, and the arc discharge characteristics when the contact materials of each embodiment and comparative example are assembled Make an evaluation.

[0145] In this embodiment, a DC high voltage relay having a double-break structure similar to that of the first embodiment is prepared, and rivet-type contacts made of various contact materials are joined to the movable terminal and the fixed terminal. The size of each contact is the same as that of the first embodiment. In addition, a neodymium magnet having a magnetic flux density of 200 mT is arranged around the movable contact and the fixed contact as an arc-extinguishing magnet, and the usage amount of neodymium which is a rare earth element is reduced compared with the first embodiment. According to the measurement with a gauss meter, ...

no. 3 Embodiment approach

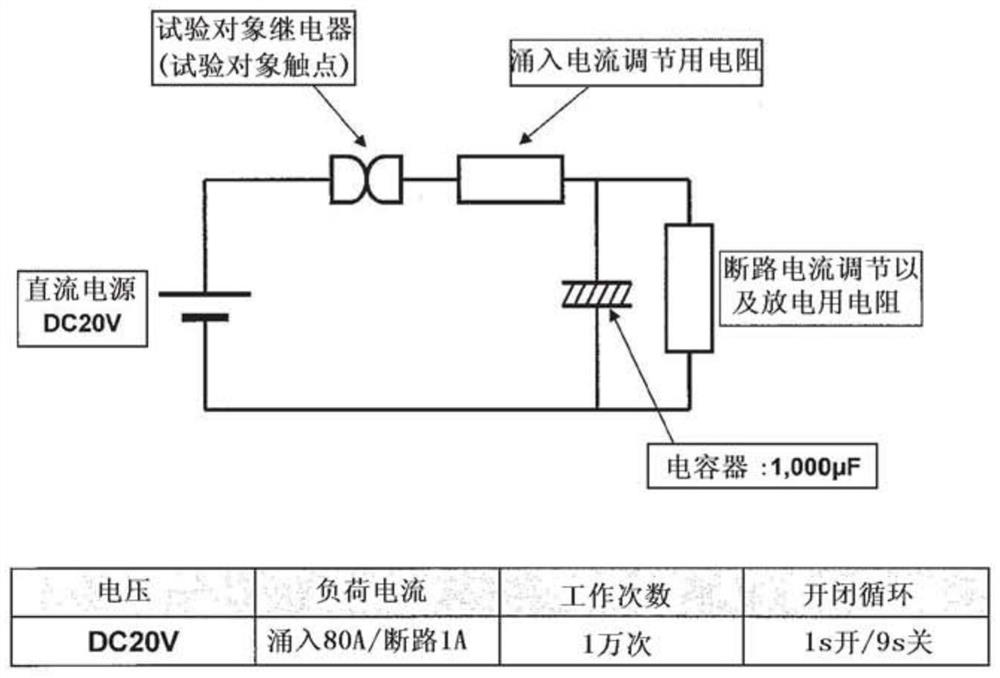

[0154] third embodiment : In the first and second embodiments, a DC high voltage relay ( figure 1 ), and a disconnection endurance test was carried out to simulate the disconnection operation when an abnormality occurred. In the present embodiment, the durability and contact resistance were evaluated when the DC high voltage relay was actually mounted as a system main relay of a hybrid vehicle or the like, and the switching operation during normal use was simulated. The normal use refers to the use condition under which the load is received by the on / off operation of the power supply of a normal circuit.

[0155] The usual conditions of use of the DC high voltage relay assumed by the present invention will be specifically described. In a DC circuit such as a hybrid car, a precharge relay suitable for the inrush current is installed to prevent the contact of the system main relay from being damaged by the high inrush current when the power is turned on. Also, after the hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com