Bearing bracket and using method thereof

A technology of bearing brackets and rotating bearings, which is applied in the field of workpiece support, can solve the problems of affecting the grinding effect of the workpiece and damage to the workpiece, and achieve the effects of ensuring the grinding effect, fast grinding, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

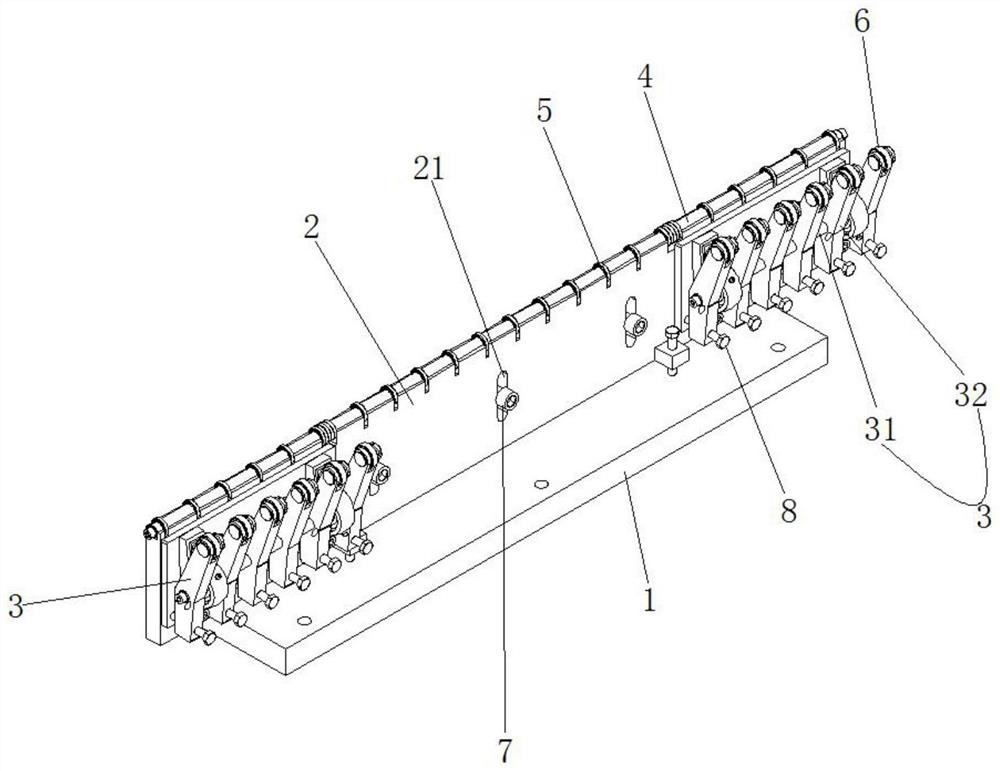

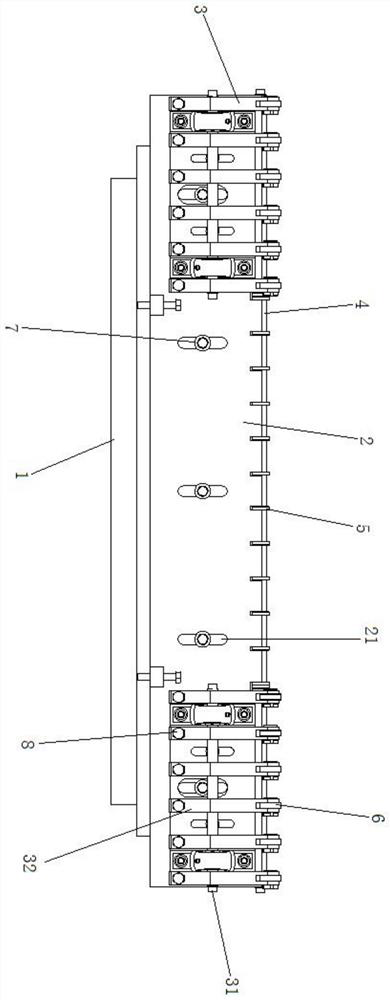

[0028] like figure 1 As shown, a bearing bracket includes a mounting bottom block 1, a side stopper 2 located on one side of the mounting bottom block 1, and a rotating group 3 for adjusting the supporting area of a workpiece.

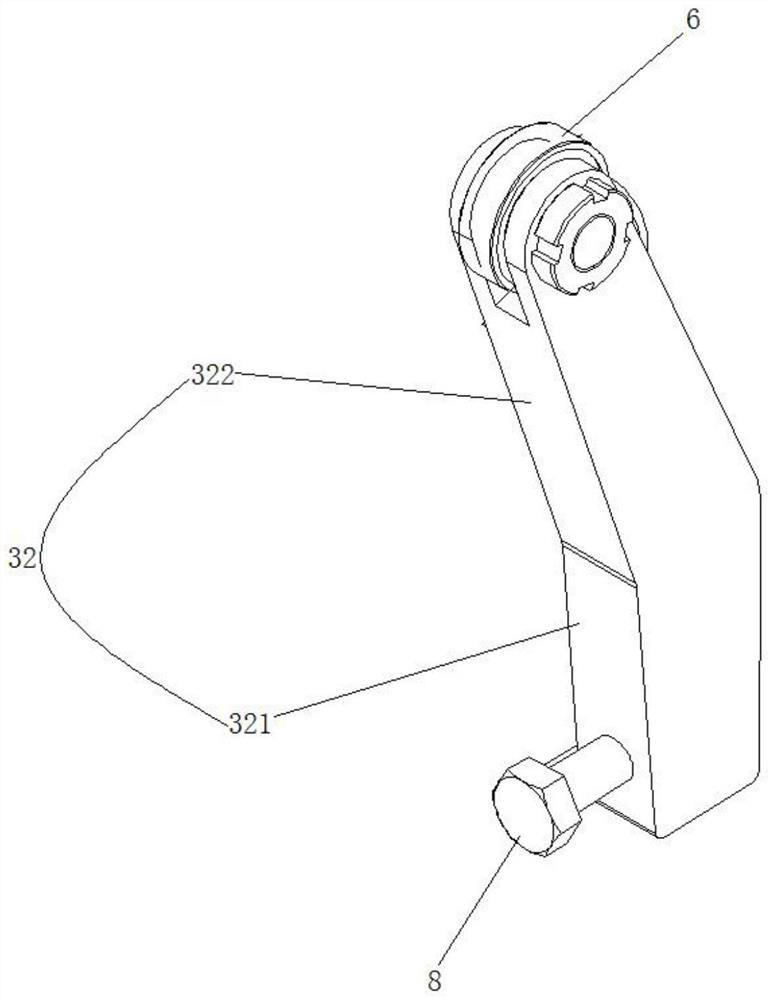

[0029] to combine figure 1 and figure 2 As shown, the side block 2 is provided with a fixed shaft 4, the fixed shaft 4 is covered with a rotating bearing 5, and the side block 2 is provided with an installation hole 21 for the installation of the rotation group 3, and the installation hole 21 is provided with a lock With screw 7, the rotating group 3 is connected with the side stopper 2 through the mounting plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com