Washing machine water level detection method and washing machine

A technology of water level detection and washing machine, which is applied in the control device of washing machine, washing device, textile and paper making, etc. It can solve the problems of uncertainty, increasing the overall cost of washing machine, and the inability to detect water level, so as to achieve accurate water level detection and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

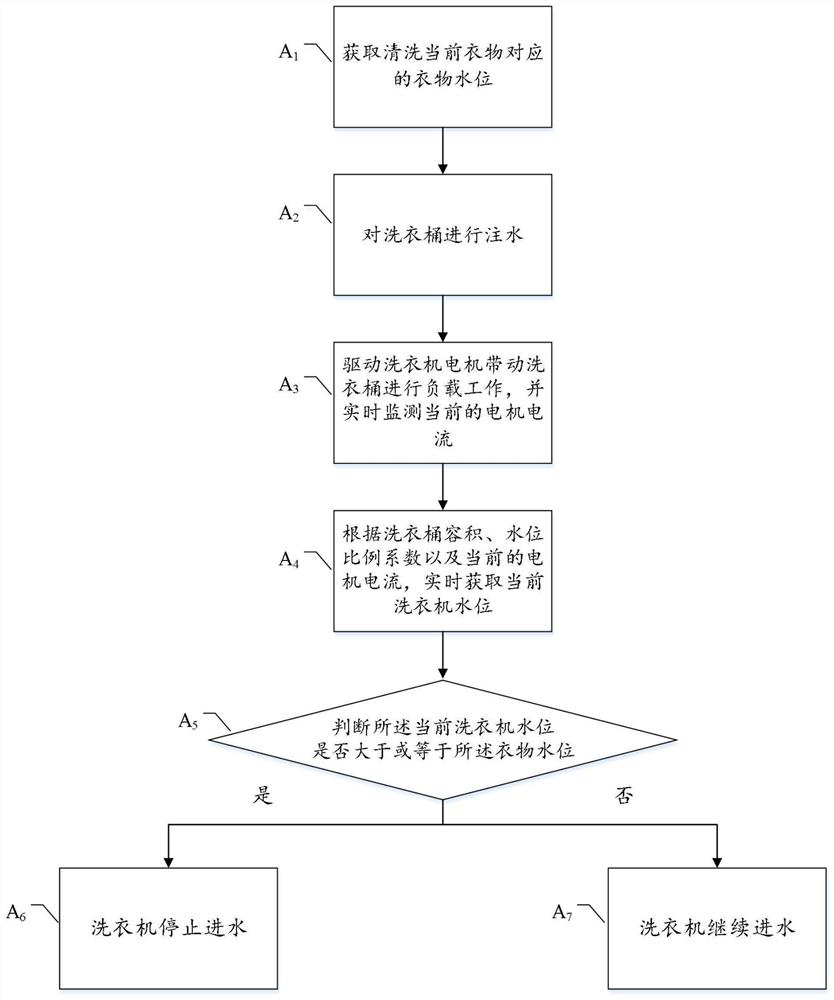

[0055] After the pre-preparation process is completed, call the data relationship provided by the pre-preparation process to drive the washing machine to fill water and load work, and judge whether to continue to enter water according to the current washing machine water level obtained in real time.

[0056] figure 1 It is a schematic diagram of the water inlet control flow of a washing machine shown in the embodiment of this application. For the water inlet control flow of a washing machine provided in the embodiment of this application, please refer to figure 1 .

[0057] A1. Get the laundry water level corresponding to the current laundry.

[0058] The laundry water level corresponding to the current laundry can be calculated according to the current laundry weight, and the laundry water level set by the user through the washing machine controller can also be obtained.

[0059] According to the weight of the current clothes, calculate the water level of the clothes corres...

Embodiment 2

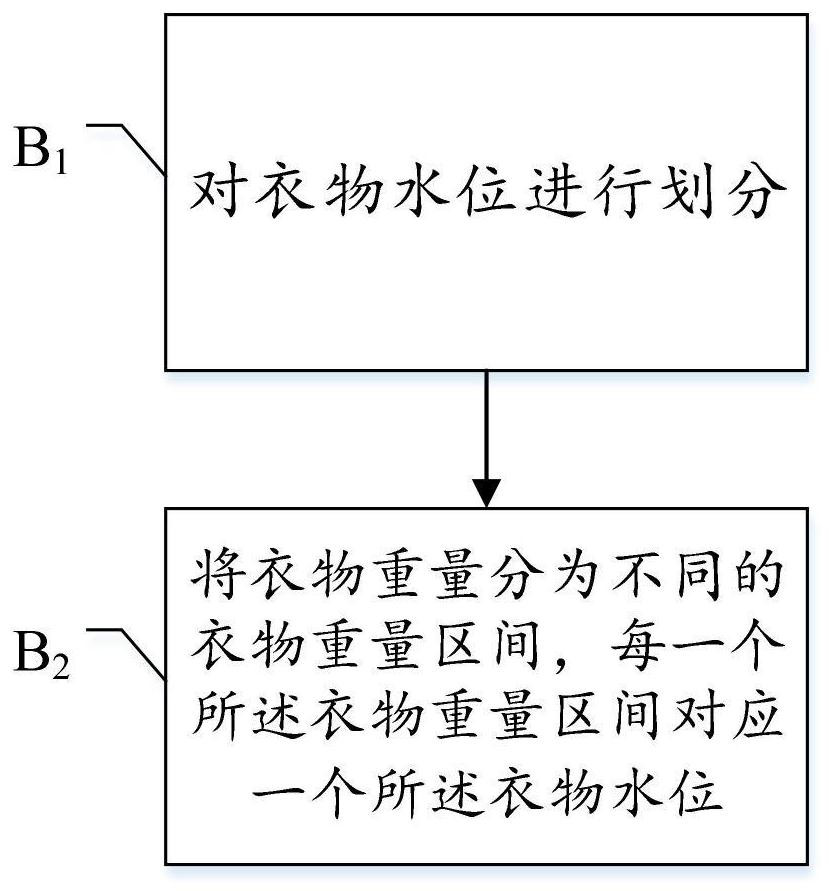

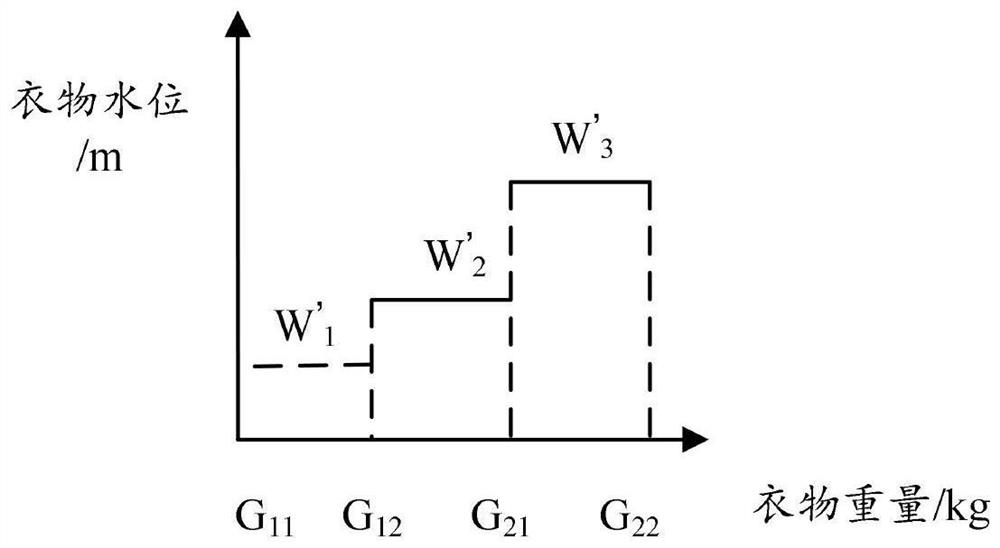

[0096] Before the water inlet control process of the washing machine, a pre-preparation process is required to divide the water level of the clothes and divide the weight of the clothes into different clothes weight intervals, so as to provide data grouping and data correspondence for the water inlet control process of the washing machine.

[0097] figure 2 It is a schematic diagram of a washing machine pre-preparation flow shown in the embodiment of the present application. For a washing machine pre-preparation process provided by the embodiment of this application, please refer to figure 2 .

[0098] B1. Divide the water level of the clothes.

[0099] Make the washing machine rotate when the bucket is empty, and calculate the water level W of the clothes in the empty bucket according to the current of the washing machine motor at this time 1 ;

[0100] The washing machine is rotated when the bucket is filled with water, and the water level W of the full bucket of cloth...

Embodiment 3

[0116] Figure 4 It is a structural schematic diagram of a washing machine shown in the embodiment of this application.

[0117] see Figure 4, the embodiment of the present application provides a washing machine, which is used to implement the washing machine water level detection method described in Embodiment 1 and Embodiment 2, and the washing machine includes:

[0118] The water level obtaining unit 401 is used to obtain the water level of the clothes corresponding to the current clothes to be washed, and instruct the water injection unit to enter water through the washing machine controller;

[0119] The water injection unit 402 is used for filling the washing tub with water according to the instructions of the washing machine controller;

[0120] The current monitoring unit 403 is used to drive the washing machine motor to drive the washing tub to perform load work, and monitor the current current of the washing machine motor in real time;

[0121] The washing machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com