Abnormal prediction operation and maintenance system and method for operation equipment

A technology for operating equipment and operation and maintenance systems, applied in the field of operation and maintenance systems, can solve the problems of low inspection efficiency, low maintenance efficiency, and heavy workload of staff inspection and maintenance, and achieve convenient one-click viewing and operation efficiency Guarantee and improve the effect of production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

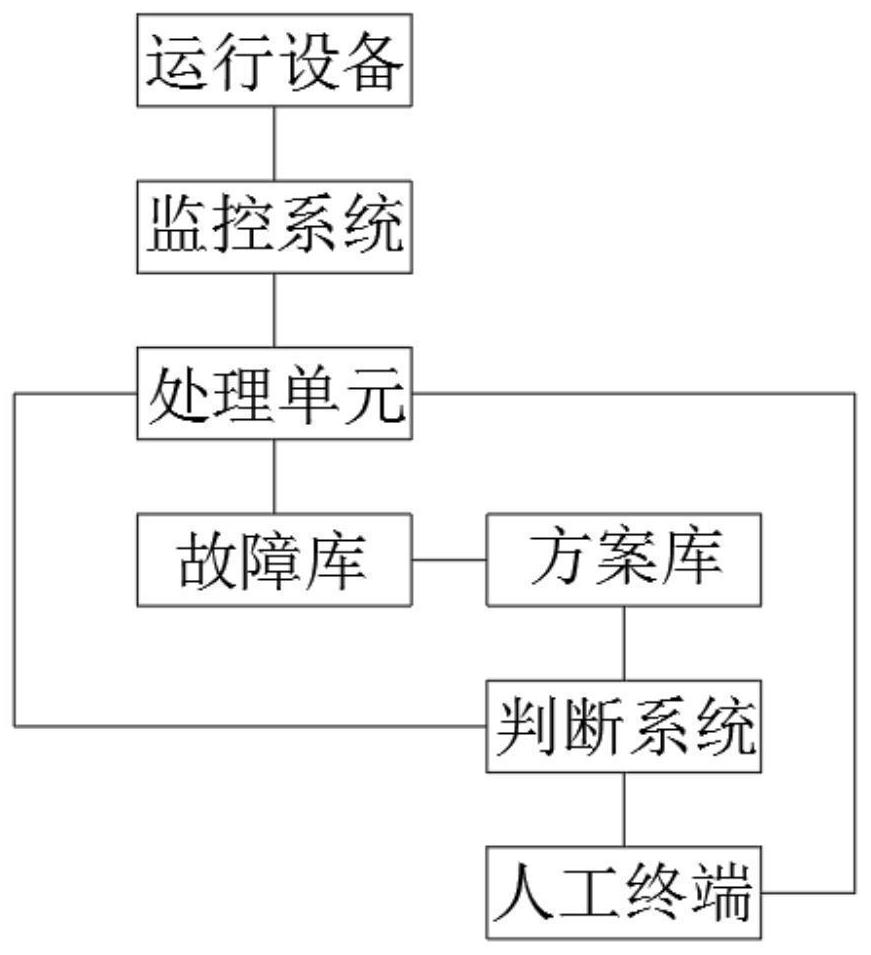

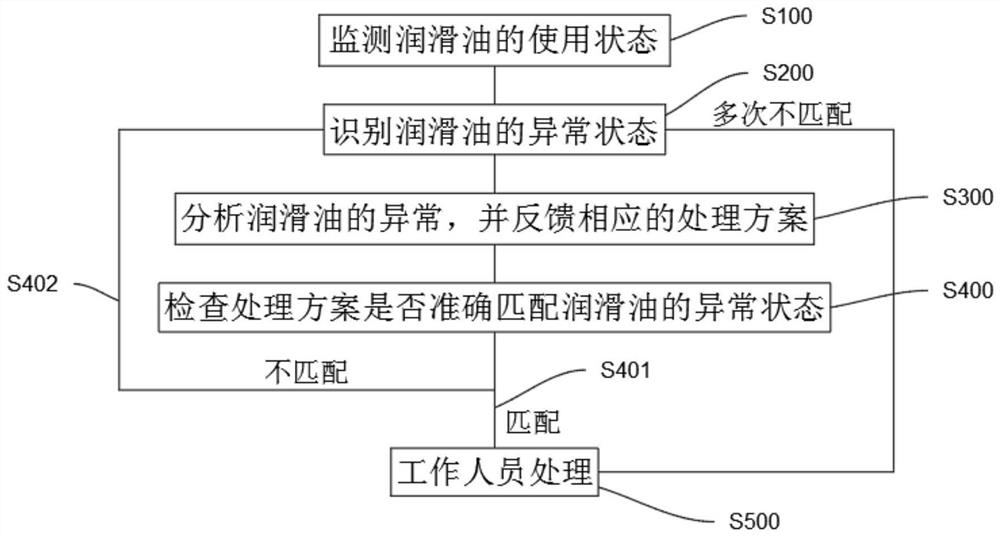

[0033] Such as figure 1 As shown, an abnormality prediction operation and maintenance system for operating equipment includes at least one operating equipment, as well as a monitoring system, an identification system, an analysis system, and a judgment system; the monitoring system is set on the operating equipment to monitor the lubrication The use status of the oil; the identification system is electrically connected to the monitoring system, and judges whether there is any abnormality in the operating equipment through the use status of the lubricating oil; the analysis system is electrically connected to the identification system to provide reference for the abnormal operating equipment Solution; the judging system is electrically connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com