Clam culture equipment with sand spitting device

A technology of clams and equipment, applied in the field of clams breeding equipment, can solve the problem of inability to spit out sand by clams, and achieve the effects of avoiding being blocked, facilitating water change, and promoting sand spit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

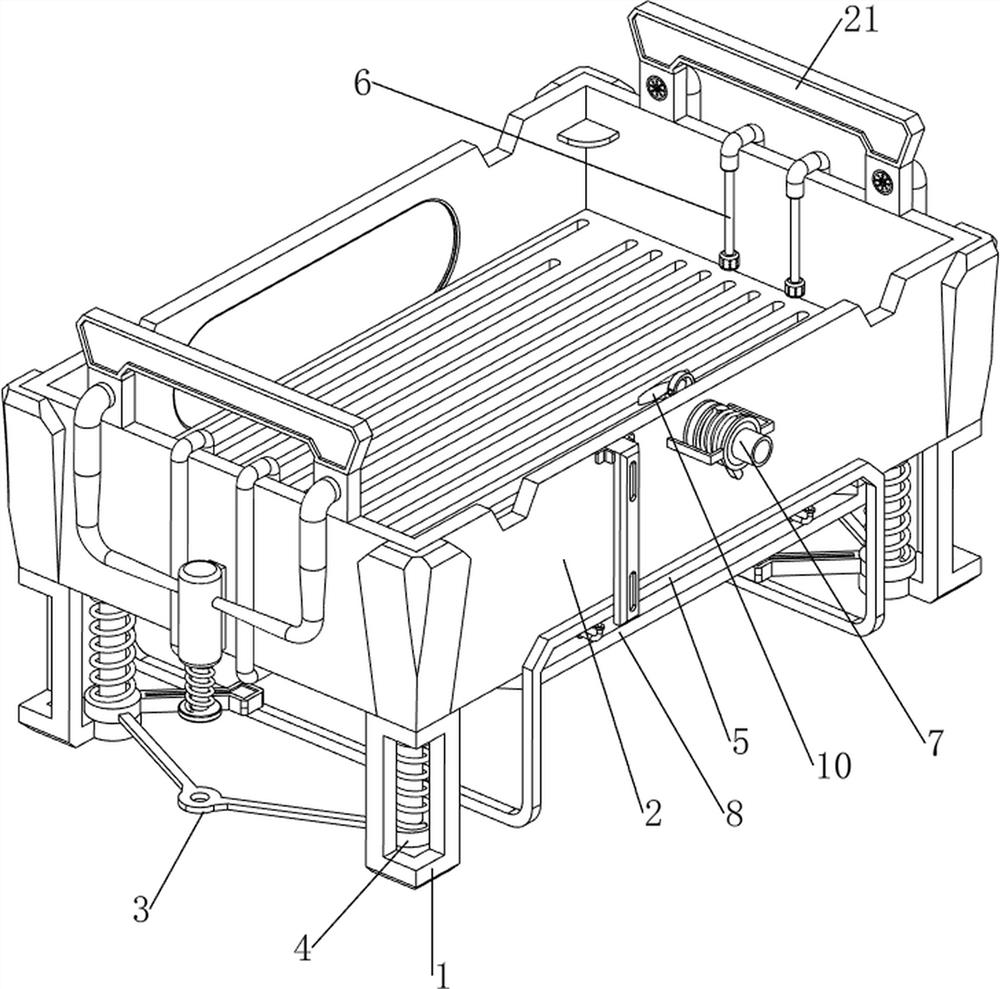

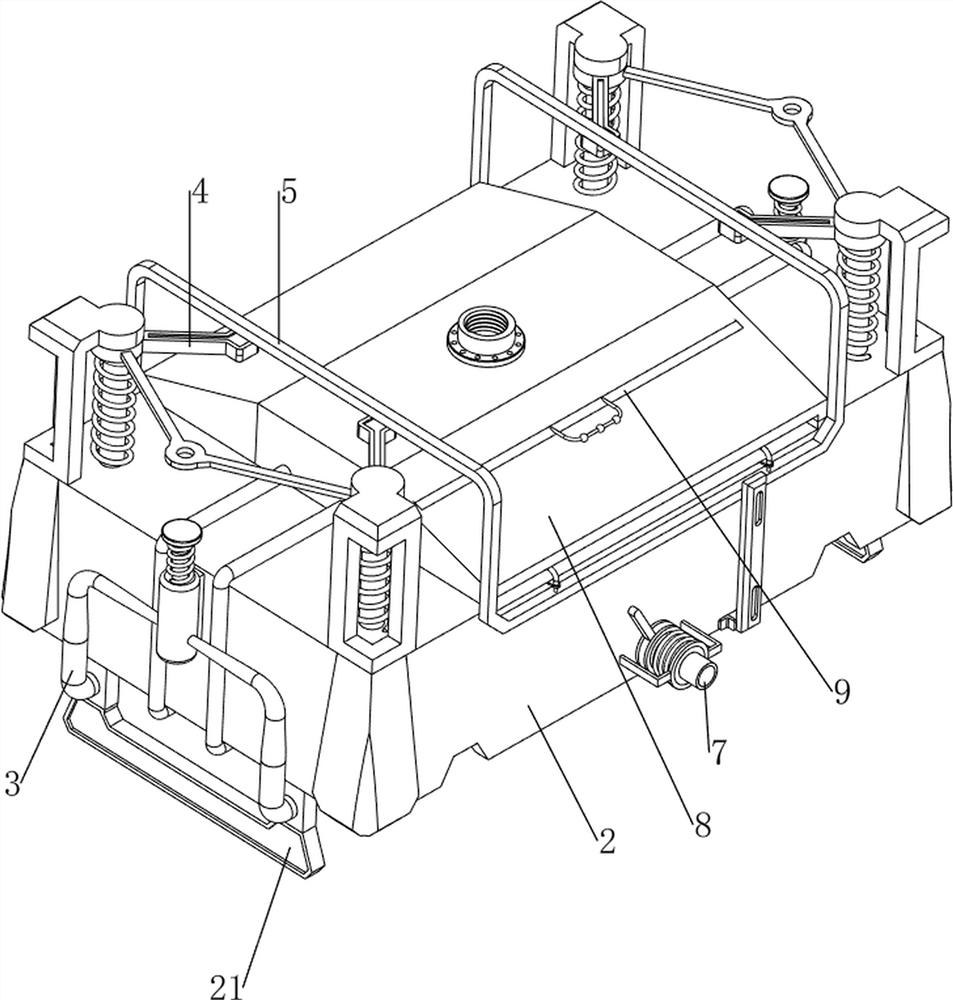

[0038] A kind of clam breeding equipment with sand-spitting device, such as figure 1 , image 3 , Figure 6 and Figure 9 Shown, include supporting leg 1, culture box 2, handle 21, lifting mechanism 4, spit sand mechanism 3 and opening and closing mechanism 5, all left and right sides are symmetrically connected with supporting leg 1 at the bottom of breeding box 2, on breeding box 2 Side left and right symmetrical formulas are connected with handle 21, and breeding box 2 is provided with opening and closing mechanism 5, and supporting leg 1 is provided with lifting mechanism 4, and lifting mechanism 4 is provided with spit sand mechanism 3.

[0039] Such as Figure 9 As shown, the lifting mechanism 4 includes a contact plate 41, a connecting rod 42, a second return spring 43 and a sieve plate 44. The inside of the culture box 2 is slidably provided with a sieve plate 44 for placing clams. Connecting rod 42 is connected, and connecting rod 42 slides through breeding box 2, a...

Embodiment 2

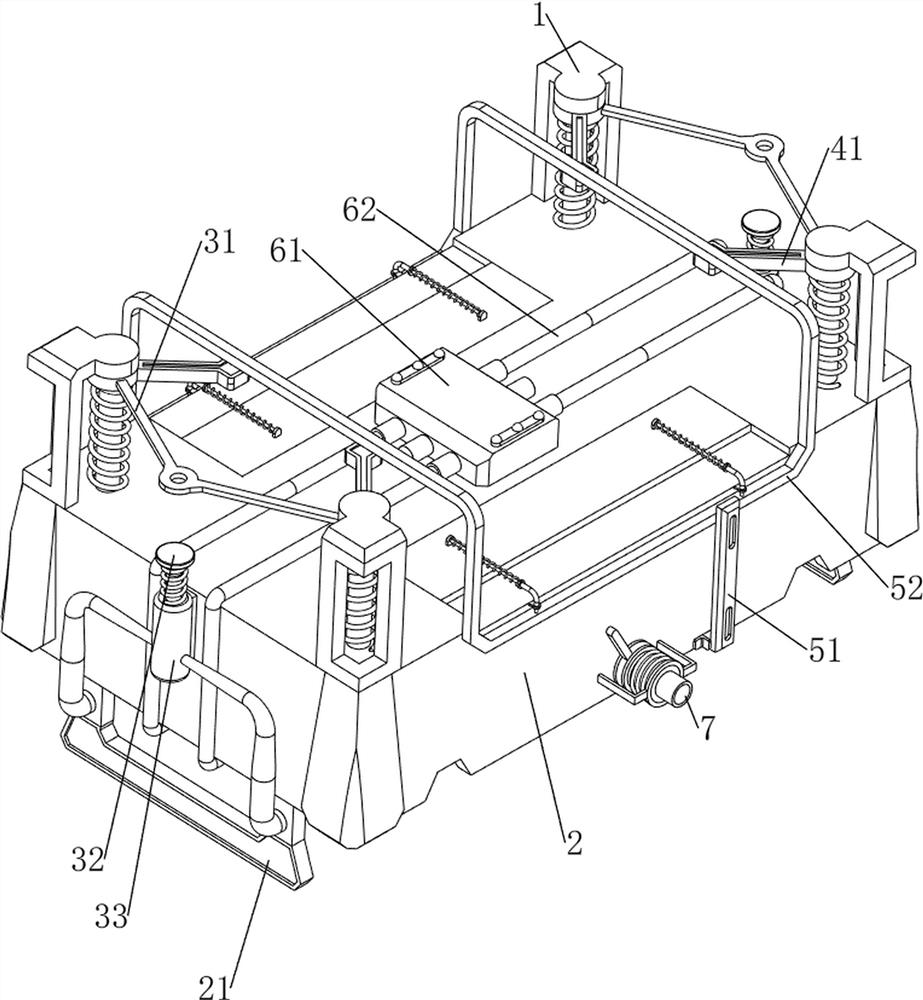

[0044] On the basis of Example 1, such as figure 1 , Figure 5 and Figure 7 Shown, also include aeration mechanism 6, and aeration mechanism 6 includes aeration pump 61, second air delivery pipe 62, flexible pipe 63 and aeration head 64, and the middle side of culture box 2 bottoms is installed by the mode of screw connection. Oxygenation pump 61, the left and right sides of oxygenation pump 61 are connected with second air pipe 62 symmetrically, the upper part of second air pipe 62 is connected with flexible pipe 63, and the lower side of flexible pipe 63 is connected with oxygen increasing head 64.

[0045] When cultivating Meretrix meretrix, the operator starts the oxygenation pump 61, and the oxygenation pump 61 delivers air to the oxygenation head 64 through the second air delivery pipe 62 and the hose 63, and the oxygenation head 64 delivers the air to the breeding box 2 In this way, the oxygenation operation can be performed on the clams. When the sieve plate 44 move...

Embodiment 3

[0047] On the basis of Example 2, such as figure 1 , Figure 11 , Figure 13 and Figure 14 Shown, also comprise supercharging mechanism 7, supercharging mechanism 7 comprises first connecting pipe 71, electromagnetic valve 72, torsion spring 73, supercharging block 74, installation pipe 75 and rotating ring 76, culture box 2 upper front sides The installation pipe 75 runs through, and the front side of the installation pipe 75 is evenly spaced to slide with three booster blocks 74, and the front side of the installation pipe 75 is rotated to be provided with a rotating ring 76 surrounding the booster block 74, and the inside of the rotating ring 76 is evenly spaced Three plectrums are welded on the ground, and the other end of the plectrum is inclined clockwise to the direction of the center of the rotating ring 76. The support frame 52 moves upwards and can contact the rotating ring 76. The front side of the rotating ring 76 is connected with a gasket. A first connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com