Automatic waste bagging device for sludge squeezer

A sludge press and bagging device technology, applied in packaging, transportation packaging, solid materials, etc., can solve problems such as unsatisfactory efficiency improvement effect, and achieve the effects of automatic overload protection, good sanitation conditions, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

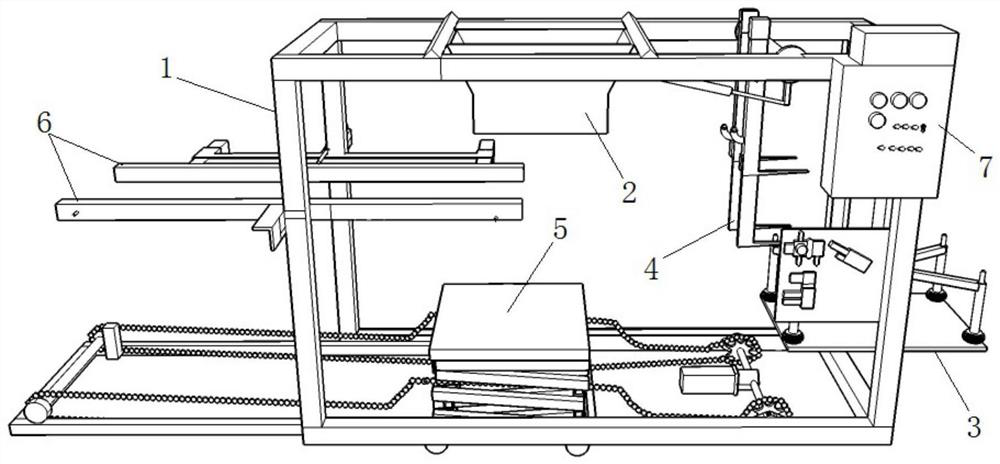

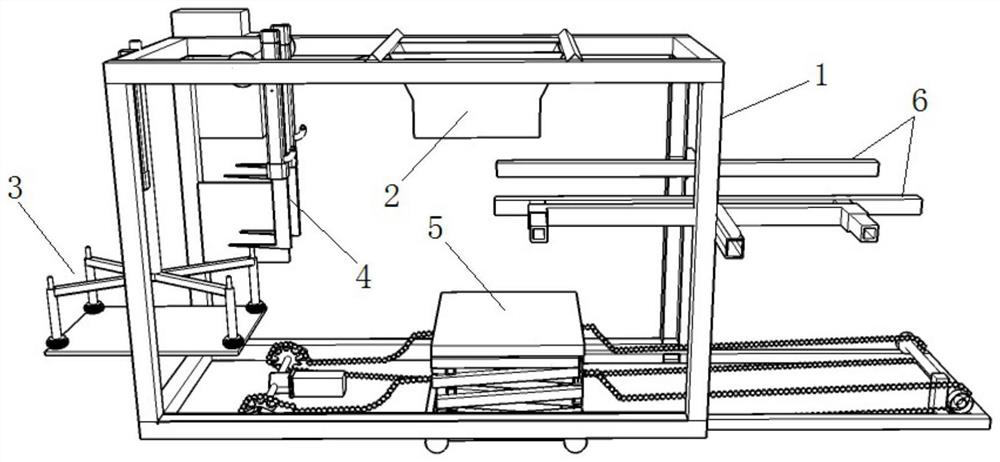

[0039] This technical solution is an automatic bagging device for sludge press waste. When working, start the switch, the electric control module 7 works, and each mechanism is in the following positions: figure 1 , figure 2 The initial position shown; at the same time, the sealing mechanism 6 enters the preheating state.

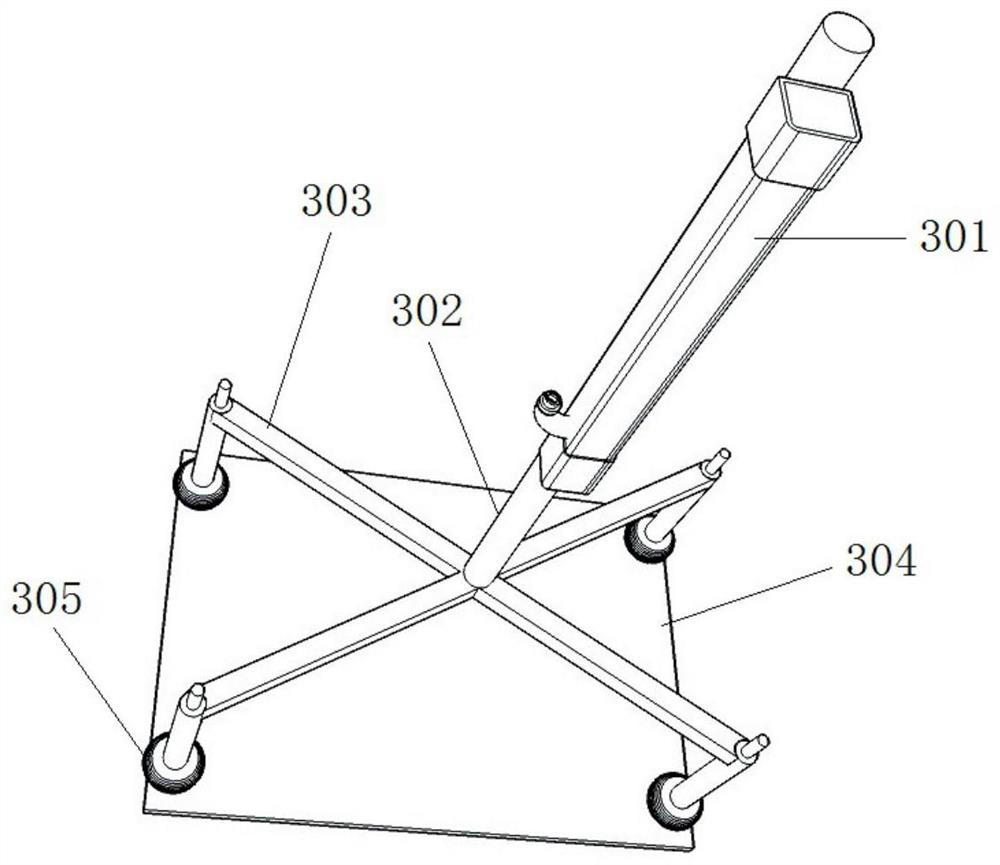

[0040] First, control the movable rod 302 to lift up, and the lifting claw 303 is lifted accordingly, the bag suction device 305 is separated from the bottom plate 304, and a number of new garbage bags in a neatly stacked state are placed on the bottom plate 304, and the opening direction of the garbage bags faces the inside of the frame 1 .

[0041] Start to work, the bottom of the cylinder A301 is air-intake, and the piston rod is pushed outwards to stretch out, and the piston rod drives the movable rod 302 to move downward, so that the suction bag device 305 contacts and compresses with the uppermost garbage bag. When picking up the bag, the front end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com