Slurry canning device and canning method

A slurry tank and slurry technology, used in liquid filling, barrel/barrel filling, etc., can solve problems such as inability to discharge air in the packaging barrel, accurate weight requirements, and potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific technical solutions of the present invention are further described below, so that those skilled in the art can further understand the present invention, without limiting their rights.

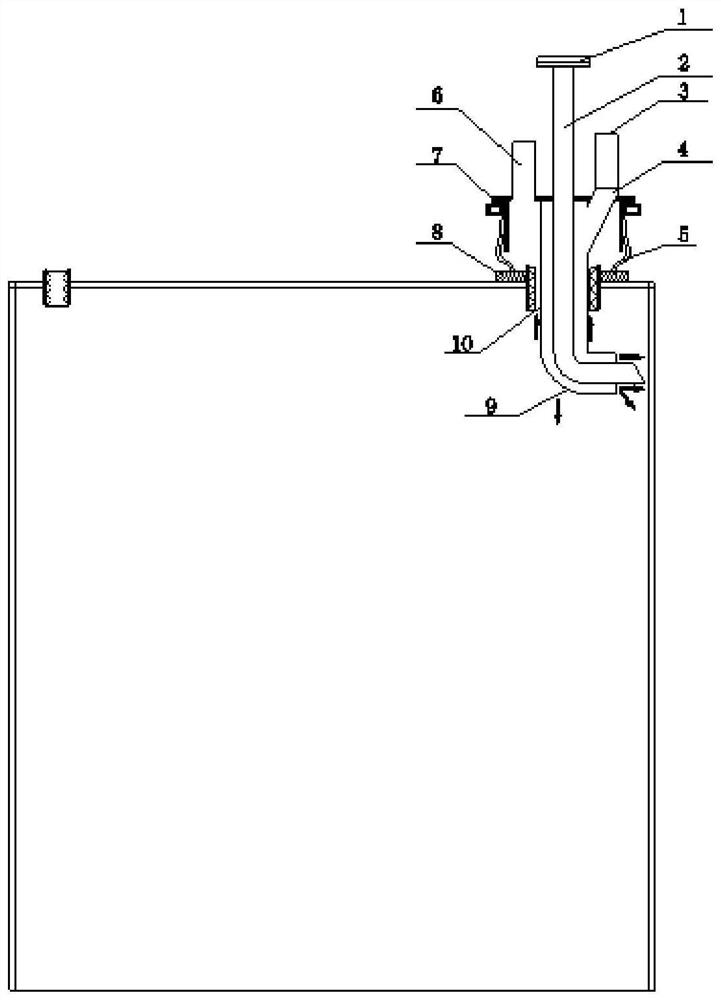

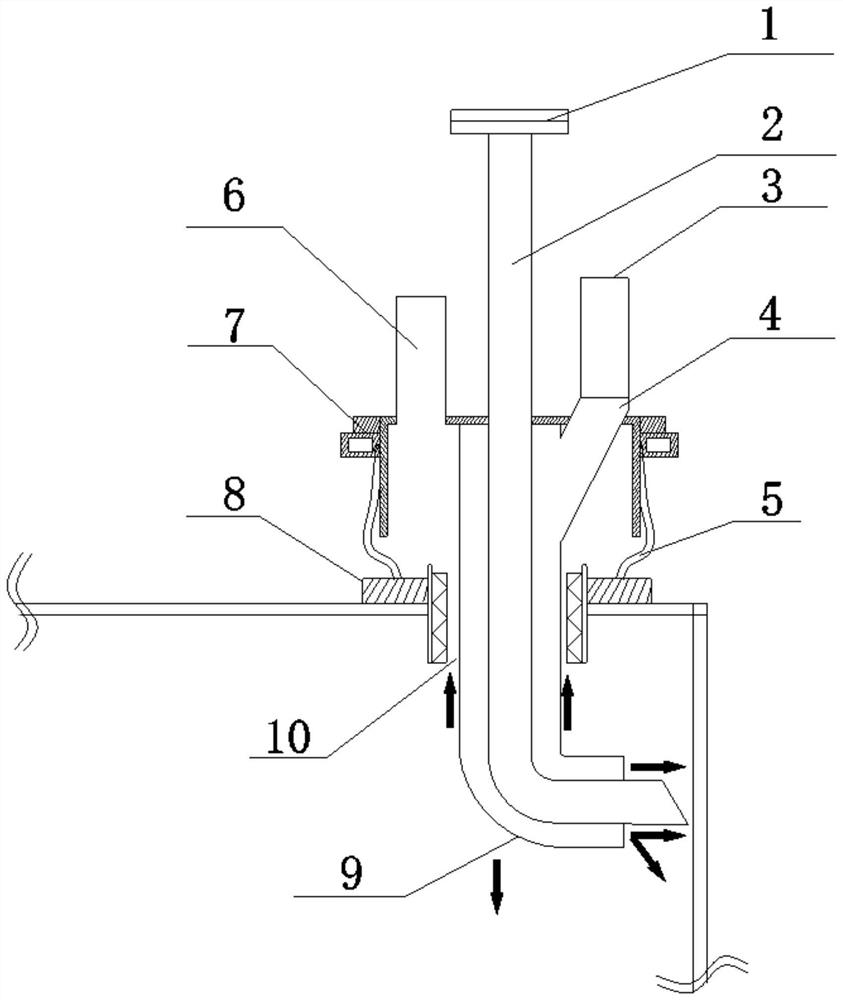

[0024] refer to Figure 1-Figure 2 , a slurry canning device, comprising a slurry packaging barrel, the slurry packaging barrel is provided with an opening, and a sealed exhaust tube is installed above the opening; the sealed exhaust tube includes an exhaust cavity and a sealing device, and the sealing The top of the device is provided with an exhaust hole 6 communicating with the exhaust cavity, and the exhaust cavity is equipped with an air intake pipe 4 that passes through the exhaust cavity and enters the slurry packaging barrel through an opening. to the feed pipe 2 in the slurry packaging barrel; the top of the sealing device is also provided with an air inlet 3 communicated with the air intake pipe, and a connection with the outer wall of the slurry packaging barrel o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com