Fabricated building embedded part and method

A pre-embedded and assembled technology, applied in building components, buildings, protected buildings/shelters, etc., can solve the problems of reducing construction progress, detachment, construction hidden dangers, etc., to prevent secondary damage and improve safety factor , reduce the effect of shedding and dumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

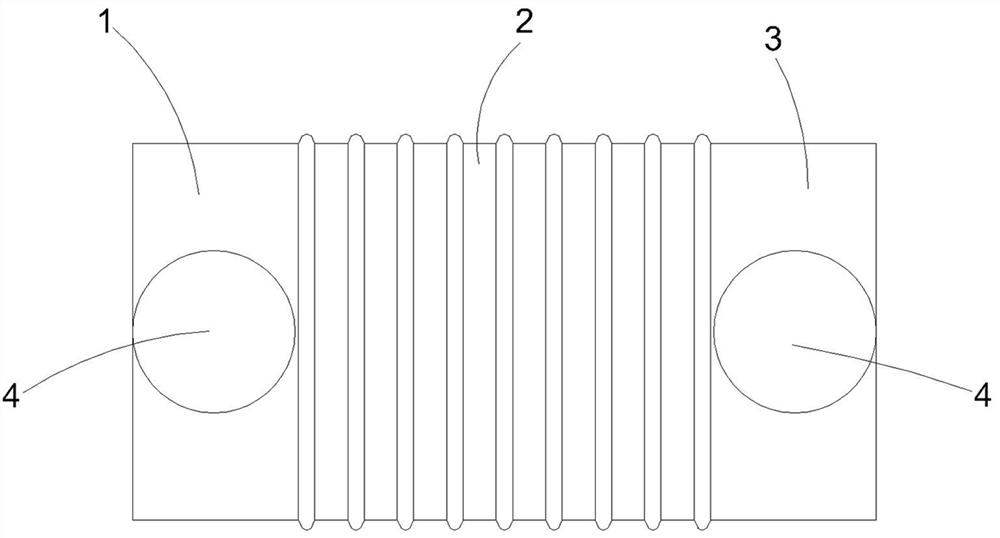

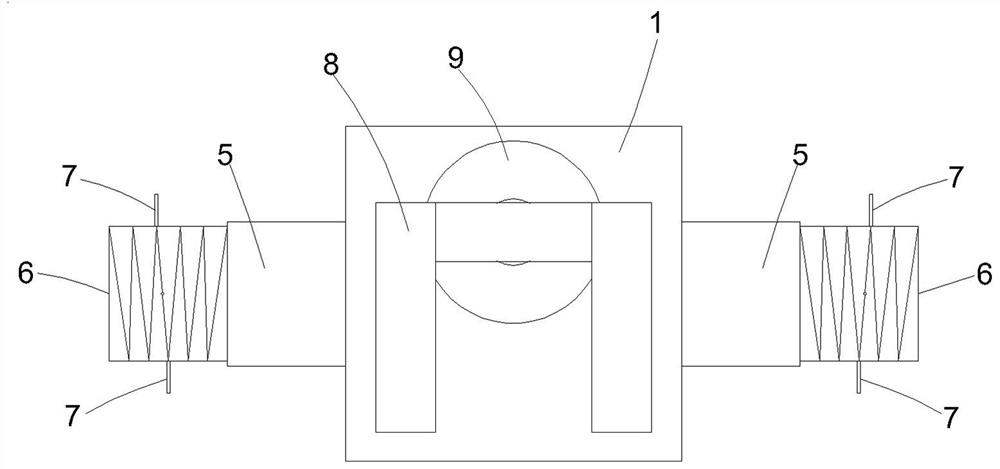

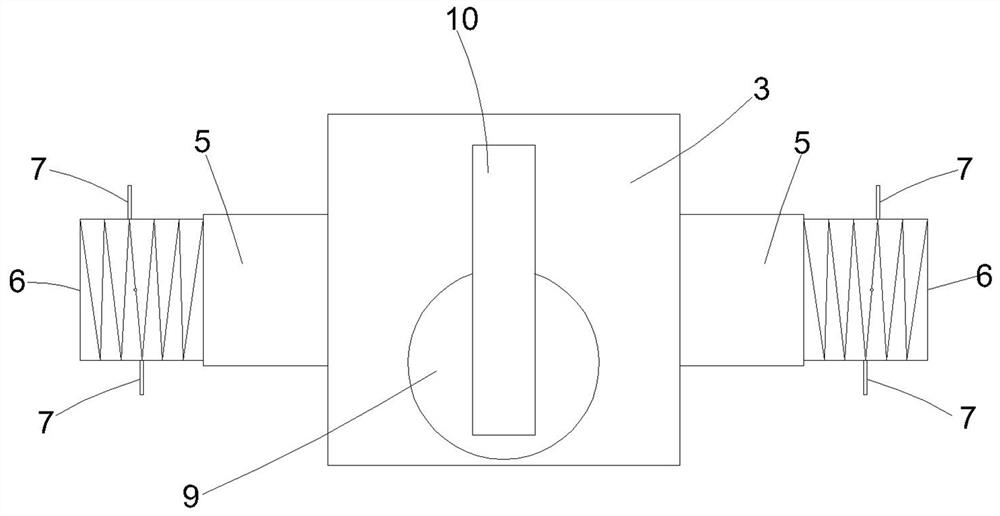

[0057] A prefabricated building embedded part, its structure is as follows Figure 1-Figure 14 As shown, among them, Figure 7 The main body limiting plate 808 and the auxiliary body limiting plate 1007 are not shown, Figure 8 The main body bracket 801 is not shown; including the embedded part body, the embedded part body includes the embedded part main body 1, the embedded part auxiliary body 3 matched with the embedded part main body 1; The anti-seismic mechanism of the embedded part matched with the auxiliary body 3 of the embedded part; the main body 1 of the embedded part and the auxiliary body 3 of the embedded part are equipped with a fixing mechanism for the embedded part. The main body 1 of the embedded part includes the main body embedded base, and the auxiliary body 3 of the embedded part includes the embedded base of the auxiliary body; The auxiliary body bracket 1001 on the side of the embedded base; the main body shock absorber 8 is provided at the end of the ...

Embodiment 2

[0077] A prefabricated building embedded part, which is different from Embodiment 1 in that: three fixing rods 7 with different lengths and clearance fits are arranged in the sleeve thread groove 601 .

Embodiment 3

[0079] A prefabricated building embedded part, which is different from Embodiment 1 in that: four fixing rods 7 with different lengths and clearance fits are arranged in the sleeve thread groove 601 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com