Method, system, and storage medium for production planning using optimized solver machines

A production planning and solver technology, applied in manufacturing computing systems, instruments, calculations, etc., to solve problems such as unexpected surges in orders, order cancellations, and production line failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present disclosure will be described with reference to the drawings.

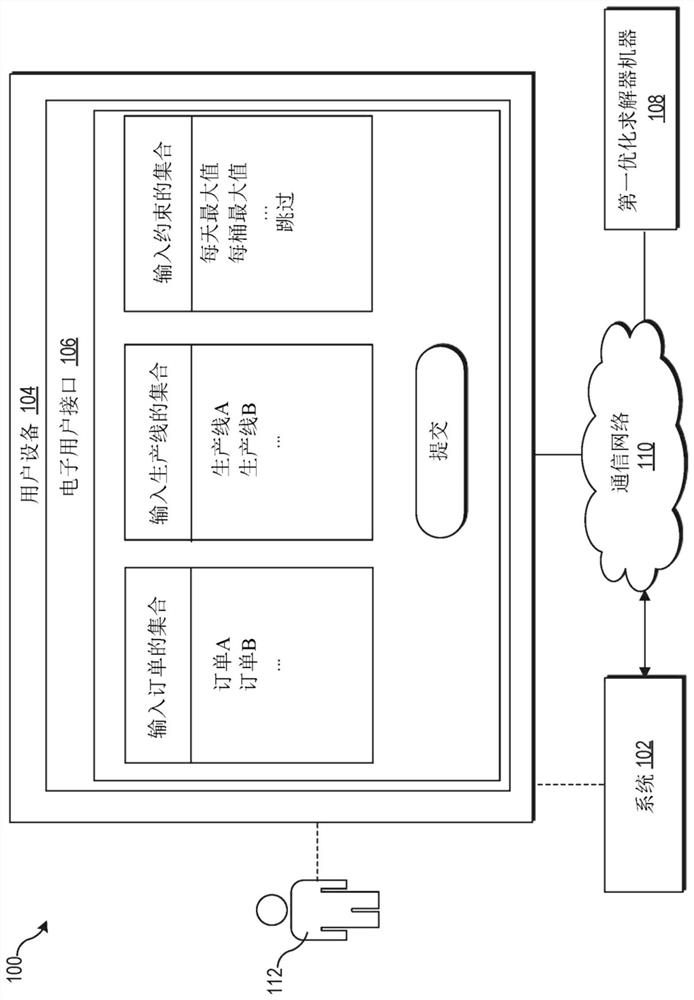

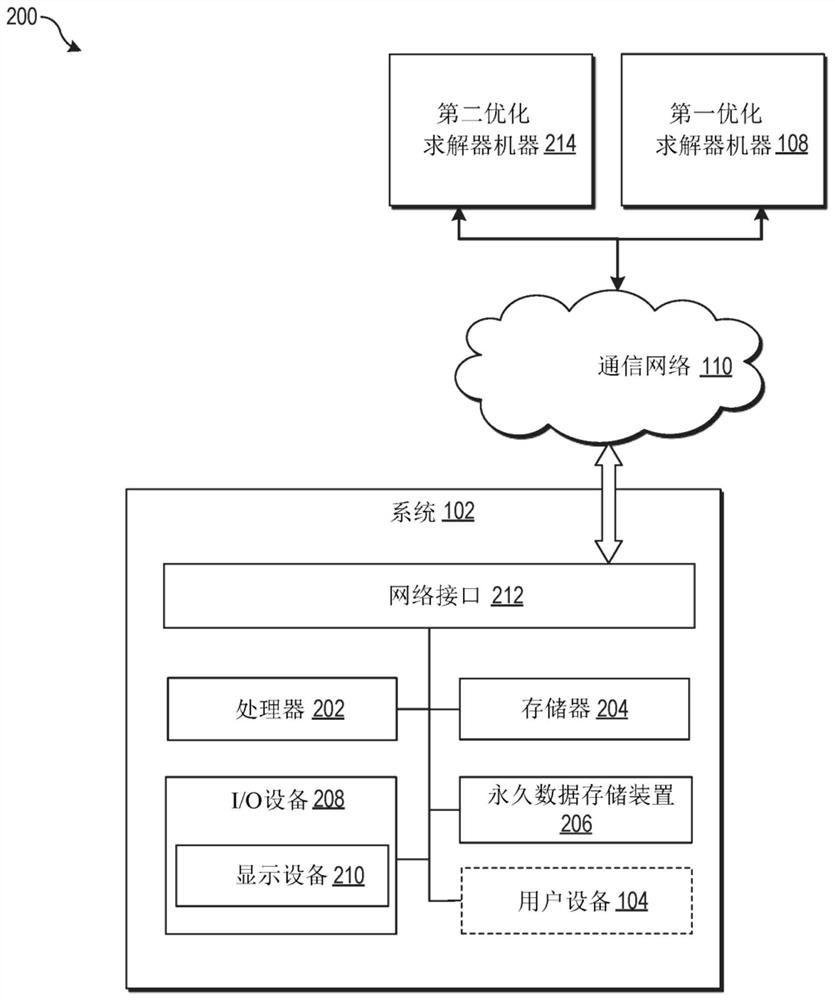

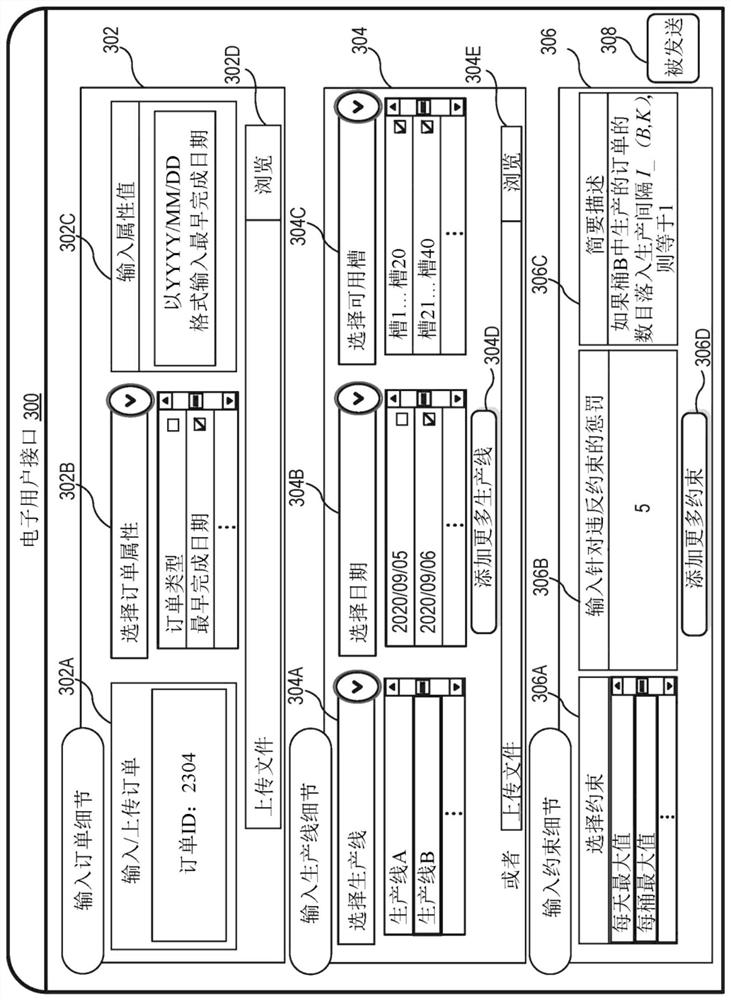

[0015] Some embodiments described in this disclosure relate to methods and systems for production planning of machines using an optimization solver. Production planning may be defined as determining a plan or schedule for producing a collection of orders at a production facility in an efficient manner. The plan or schedule must ensure that the order is ready for shipment on or before the delivery or fulfillment date. In addition, the plan or schedule must conform to most of the production-related constraints with the fewest violations of these constraints.

[0016] Typically, a production plan is used as a guide for producing orders within a production facility. Modern production or manufacturing facilities often require advanced production planning and scheduling to deliver orders on time and efficiently manage production resources. The problem of production planning is a compu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com