Clamp for plane milling of upper template of stamping die

A stamping die and plane milling technology, which is applied in the field of mold processing fixtures, can solve the problems of scattered debris falling on the ground, inconvenient use, inconvenient cleaning, etc., and achieve the effect of easy operation, convenient use, and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

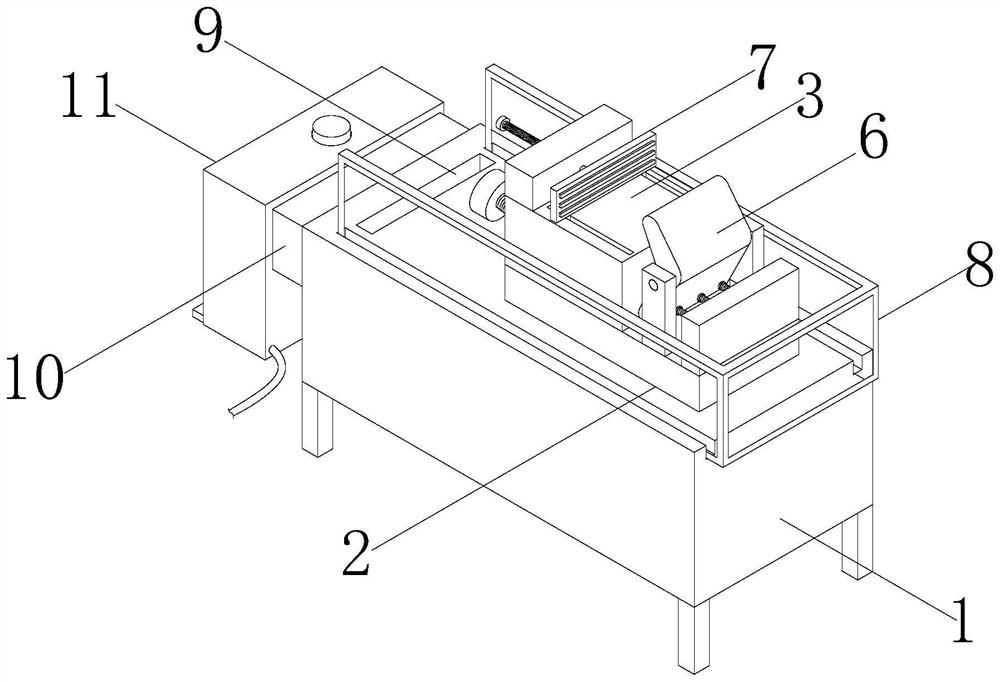

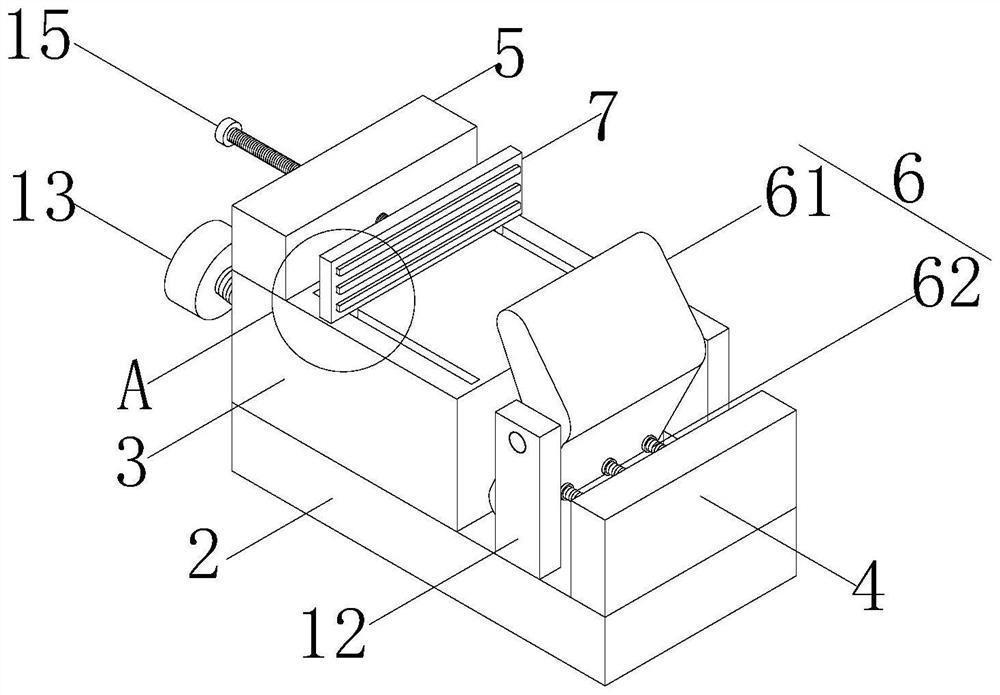

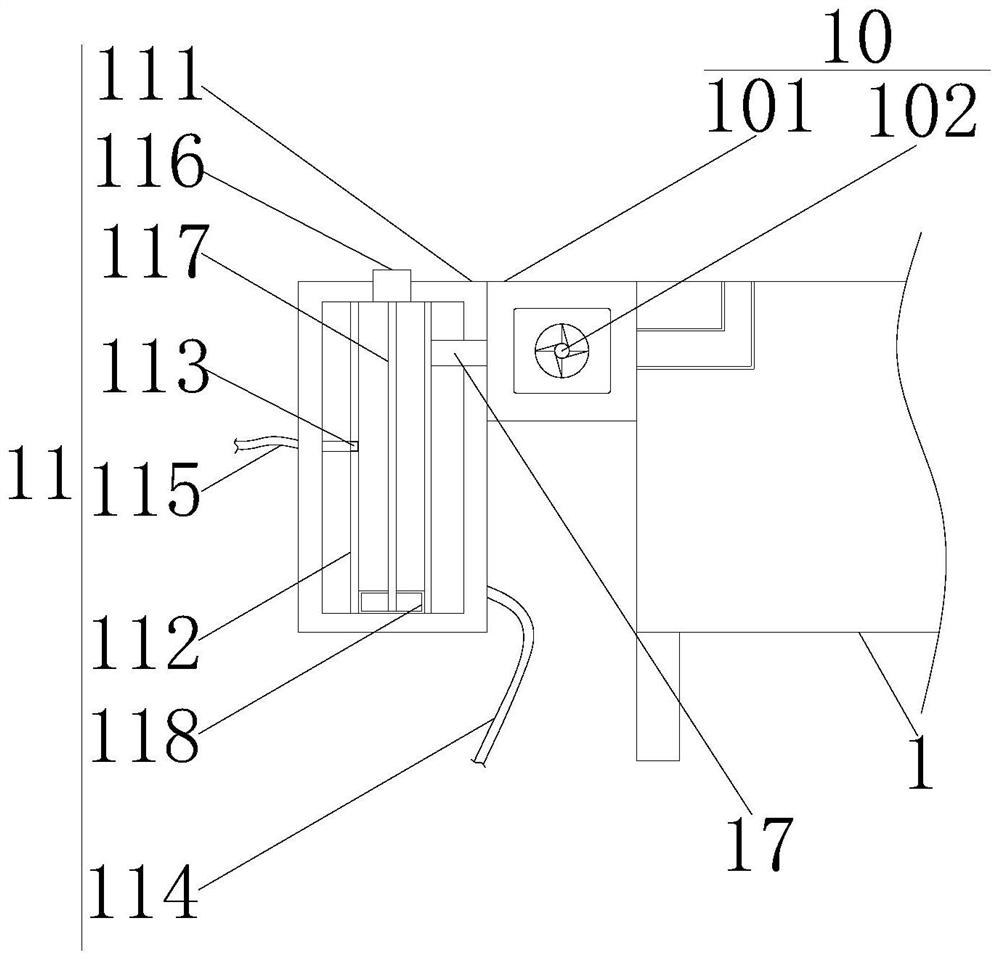

[0022] refer to Figure 1-Figure 5 , the present invention proposes a fixture for template milling on a stamping die, including a clamping seat 1, a fixing seat 2 is installed on the clamping seat 1, a card seat 3 and a first fixing block 4 are installed on the fixing seat 2, and on the card seat 3 A second fixed block 5 is installed, and a locking piece 6 for workpiece clamping is installed on the fixed seat 2, and the locking piece 6 is located between the deck 3 and the first fixed block 4, and a limit block is installed on the second fixed block 5 7 and a driving member for driving the limit block 7 to approach or move away from the locking member 6. A chute is provided on the deck 3, a slide block 14 slidably connected with the chute is installed on the limit block 7, and the driver includes a second threaded rod 15 threaded on the second fixed block 5, and the second thread One end of the rod 15 is rotatably connected to the limiting block 7 , and the end of the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com