White spirit saccharification and fermentation equipment

A saccharification fermentation and equipment technology, applied in the field of liquor saccharification and fermentation equipment, can solve the problems of difficult control of fermentation koji, low production efficiency, and affecting the quality and efficiency of brewing, so as to achieve a clean drying process, improve quality and efficiency, and prevent The effect of reverse rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

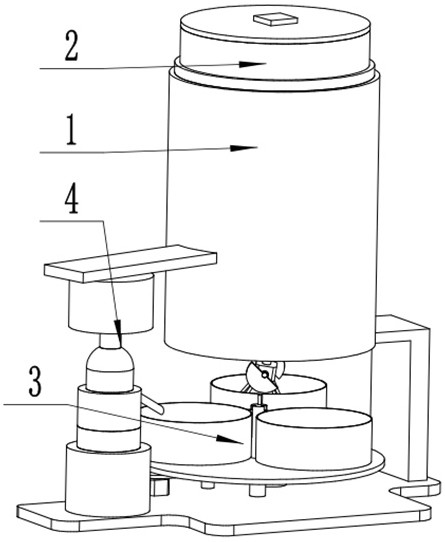

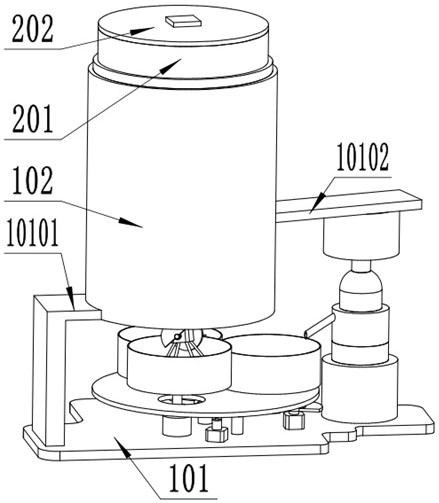

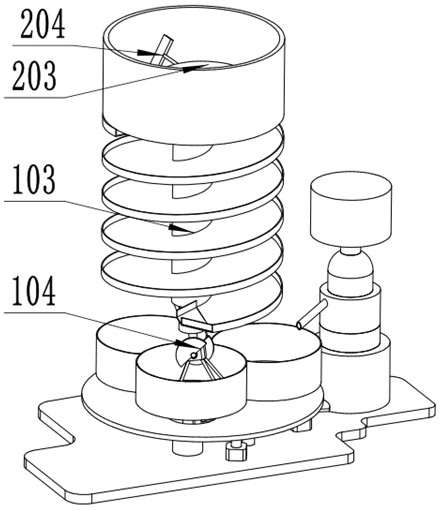

[0031] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 The liquor saccharification and fermentation equipment shown includes a conveying mechanism 1 , a toggle mechanism 2 , an intermittent mechanism 3 , and a distiller's yeast conveying mechanism 4 .

[0032] Such as Figure 8 , Figure 9 As shown in the koji delivery mechanism 4, the koji delivery mechanism 4 is arranged on the base 101, the koji tube 404 is fixedly installed on the horizontal plate 10102, the top of the ball tube 403 is fixedly installed on the bottom of the koji tube 404, and the bottom of the ball tube 403 is fixedly installed on the fixed tube 401 top, the fixed tube 401 is fixedly installed on the base 101, the fixed tube 401 is provided with a delivery tube 40101, the ball 402 is slidably installed inside the ball tube 403, and under the action of gravity, the ball 402 prevents the koji inside the koji tube 404 from fallin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com