High-voltage cable joint processing equipment based on crimping technology

A high-voltage cable and processing equipment technology, applied in the direction of connecting/terminating cable equipment, etc., can solve problems such as low efficiency, affecting cable quality, and uneven quality of cable joints, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

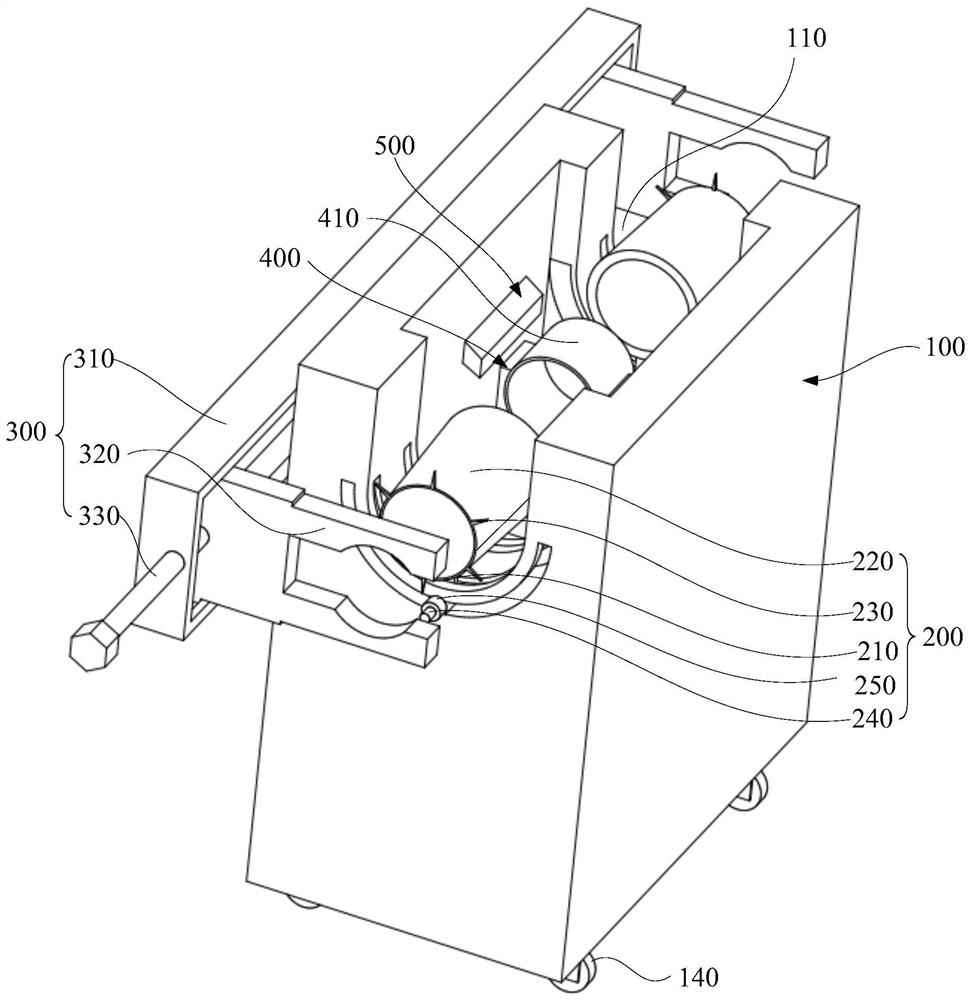

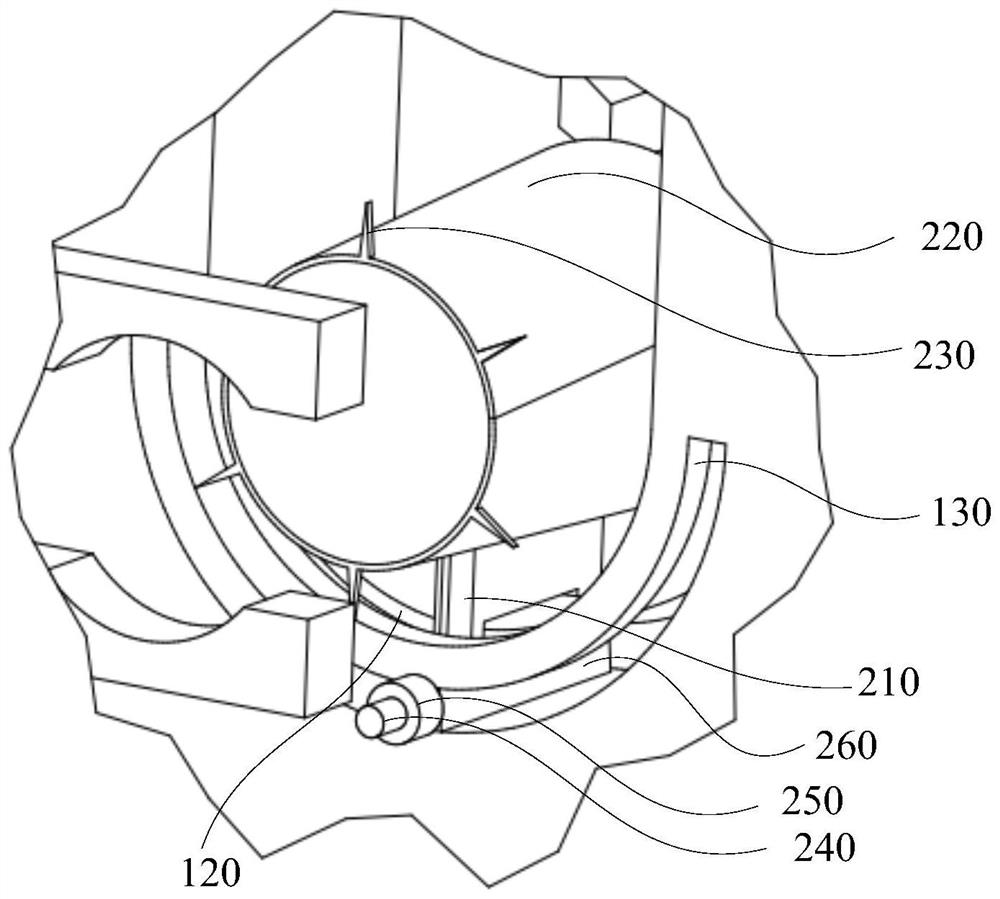

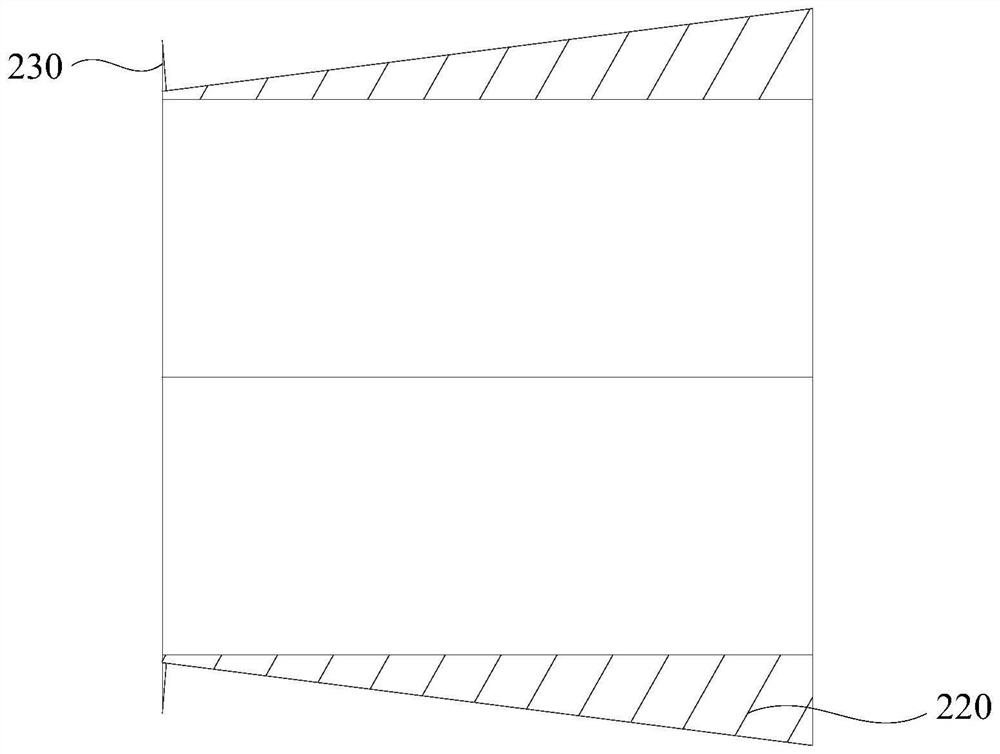

[0033] See Figure 1 to Figure 3 , The present invention provides a high-voltage cable joint processing equipment based on crimping technology, including a housing 100, a wire stripper 200, a feeding mechanism 300, a fixed sleeve bracket 400 and a hot air blower 500, for processing cable joints.

[0034] Specifically, the left and right sides of the casing 100 are provided with feeding troughs 110 communicating with the inner cavity thereof, and the feeding troughs 110 extend vertically upward to the top of the casing 100 . In order to facilitate the transportation of the entire device, universal wheels 140 are pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com