Riveting positioning jig for hot melt machine

A technology for positioning fixtures and hot melt machines, which is applied in the manufacturing of multilayer circuits, electrical components, printed circuits, etc., can solve problems such as increased cost and energy consumption, waste of manpower, and potential safety hazards, and achieves simple structure, The effect of improving riveting capacity and improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

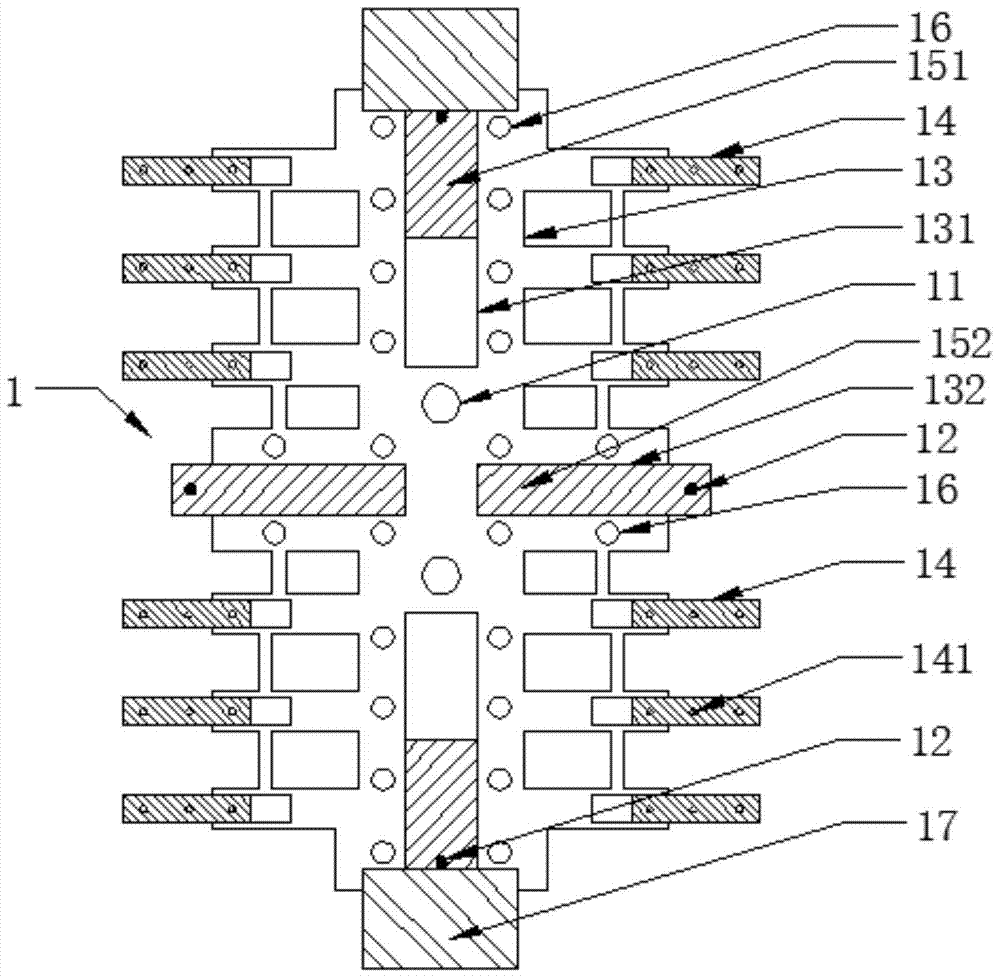

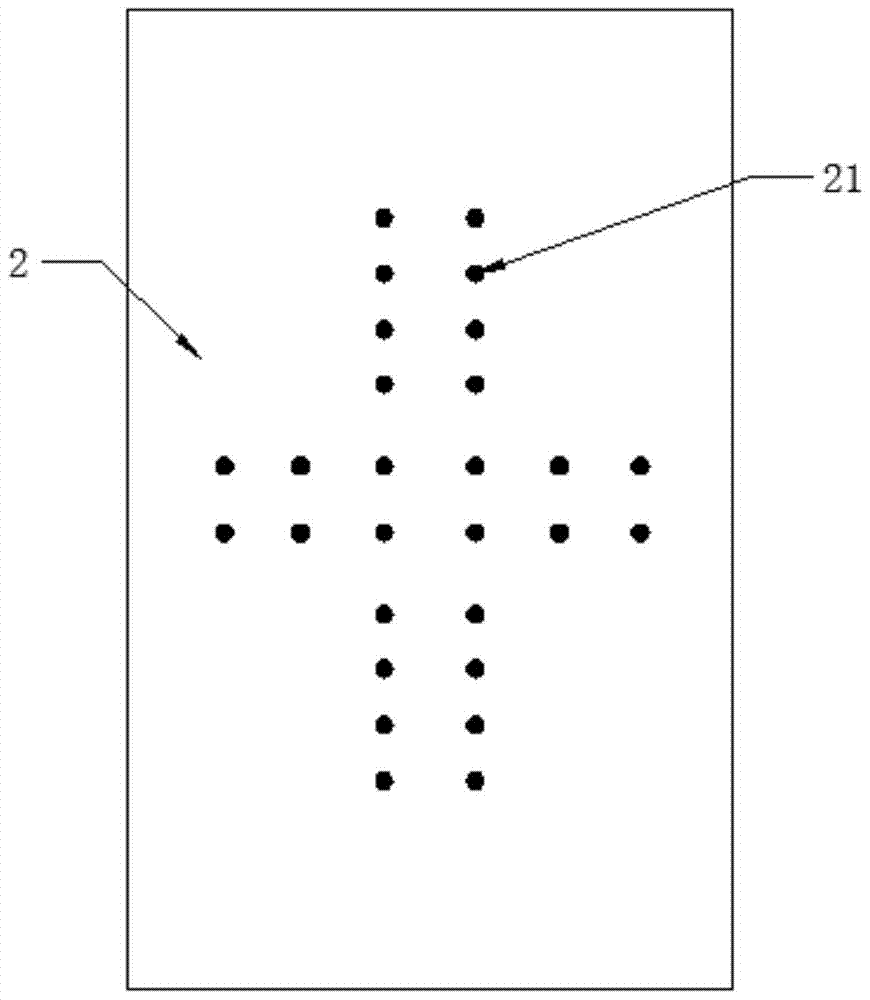

[0021] Embodiment: A riveting positioning jig for a hot-melt machine, which is composed of a combined carrier plate 1 and an ejector plate 2. There are two combined carrier plates, and the machine table of the hot-melt machine is provided with a There are two positioning pins for the combined tray, and the combined tray is provided with a positioning hole 11 corresponding to the positioning pin, and the combined tray is sleeved on the positioning pin of the machine through its positioning hole Realize the positioning connection with the machine platform. The combined tray is provided with positioning pins 12 corresponding to the alignment holes of the plate, and the plate passes through the alignment holes on the positioning pins of the combined tray to achieve positioning with the combined tray. connection, the combination tray is provided with a number of ejection holes 16, the upper surface of the ejection plate and the position corresponding to the ejection hole of the comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com