Bogie side frame of railway wagon with high dynamic performance and bogie

A railway freight car, high dynamic technology, applied in the field of bogies, can solve problems such as inability to meet cargo transportation and long-term operation of personnel, poor stability of side frames, low stability indicators, etc., to improve lateral dynamic performance, increase lateral flexibility, Reliable effect of structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The implementation of the present invention will be described in detail below in conjunction with the examples of implementation, but they do not constitute a limitation of the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

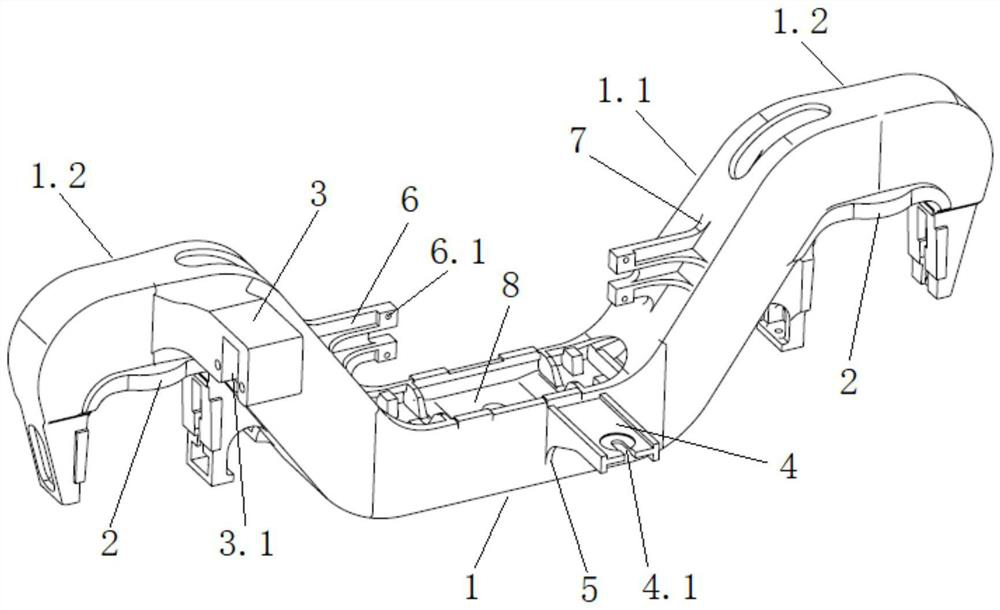

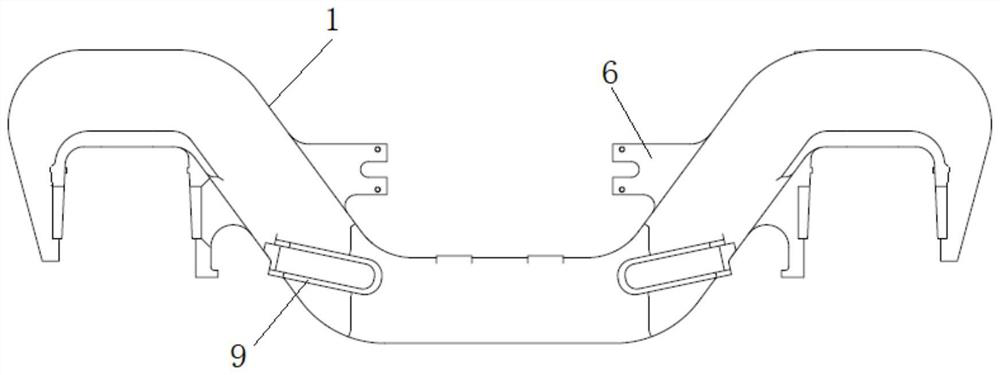

[0026] Such as figure 1 The shown bogie side frame of a high dynamic performance railway freight car includes a side frame body 1, the middle part of the side frame body 1 has a first opening structure 1.1 facing upward, and the two ends of the side frame body 1 respectively have a second opening structure facing downward. The opening structure 1.2; the first opening structure 1.1 and the second opening structure 1.2 at both ends are integrally cast; the bogie side frame of the present invention has no upper chord. Side frame pedestals 2 are symmetrically arranged at both ends of one side of the side frame body 1, and the side frame pedestals 2 are u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com