Upper thread clamping mechanism of double-needle embroidery machine

A clamping mechanism and embroidery technology, which is applied to the mechanism of embroidery machines, embroidery machines, textiles and paper making, etc., can solve the problems of unsatisfactory use effect and the inability of double-sided thread to pass efficiently and stably, so as to improve the effect of upper thread passing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

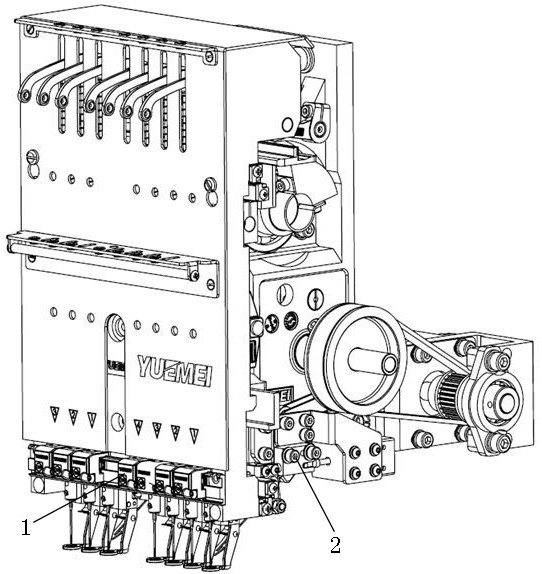

[0055] Example: such as image 3 As shown, a double-needle embroidery machine upper thread clamping mechanism includes a lower thread passing component 1 and a upper thread clamping and releasing component 2 .

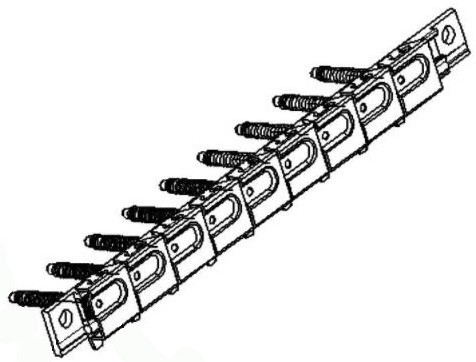

[0056] Such as Figure 4 with Figure 5 As shown, the lower thread passing assembly 1 includes a pressing bar aluminum seat 1-1, a pressing line spring seat 1-2, a pressing line spring 1-3, a pressing piece 1-4, a line passing ejector rod 1-5, and a soft rubber pressing bar 1 -6 and wire rods 1-7.

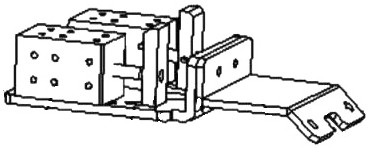

[0057] Such as Figure 8As shown, the layered aluminum seat 1-1 is used to connect with the needle bar frame, the layered aluminum seat 1-1 is in the shape of a long plate, and the layered aluminum seat 1-1 is provided with a plate seat connection hole for connecting with the needle bar frame 1-1-5, bead aluminum seat 1-1 just can realize the detachable connection with needle bar frame through plate seat connection hole 1-1-5 and bolt. The beaded aluminum base 1-1 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com