Quick self-clamping heart-shaped fixture

A heart-shaped fixture and self-clamping technology, which is applied in the direction of clamping, manufacturing tools, supports, etc., can solve the problems of slipping and instability, easy to produce impact, and grinding into concave arcs, etc., to achieve reliable clamping force and prevent chipping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing.

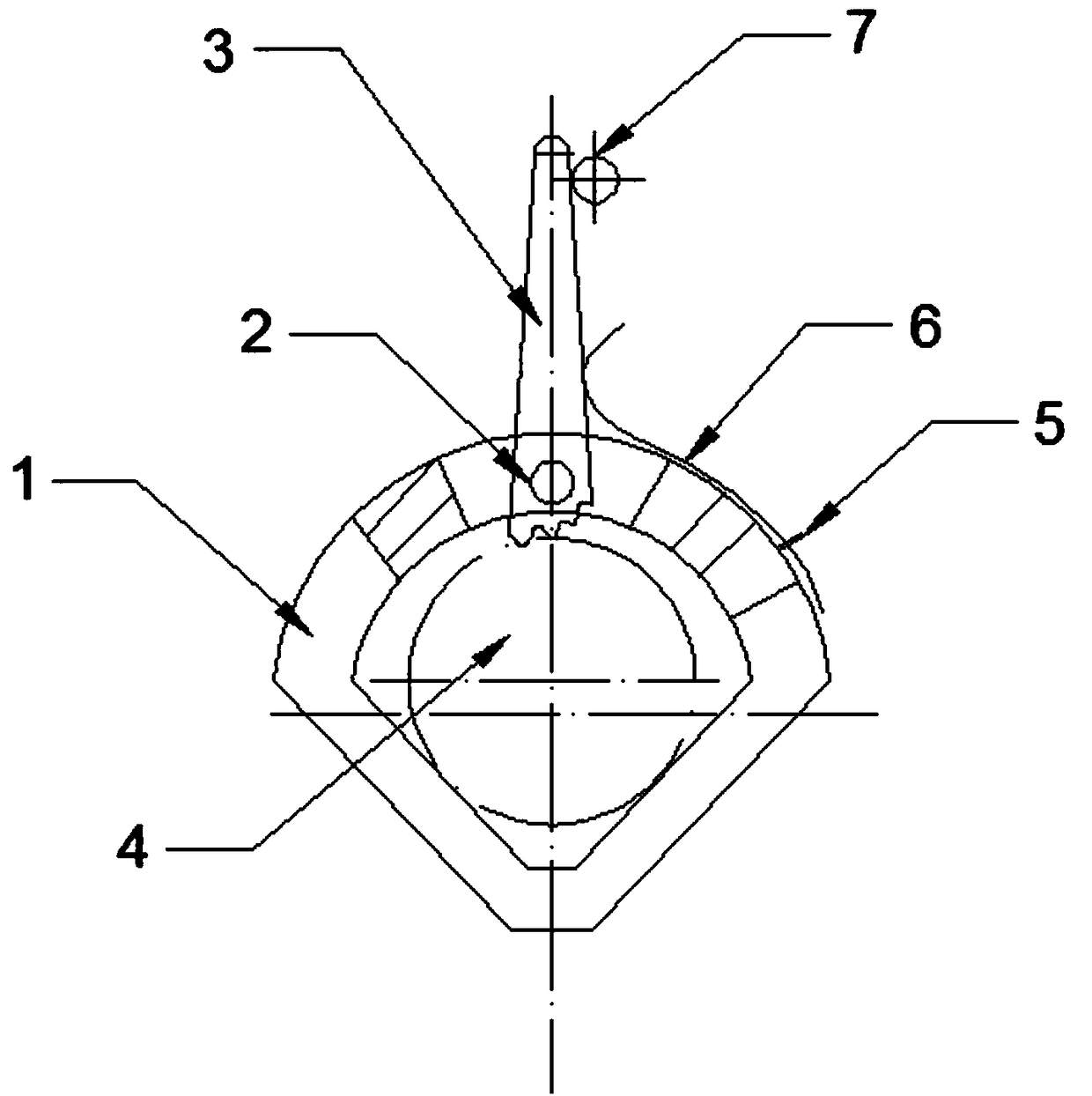

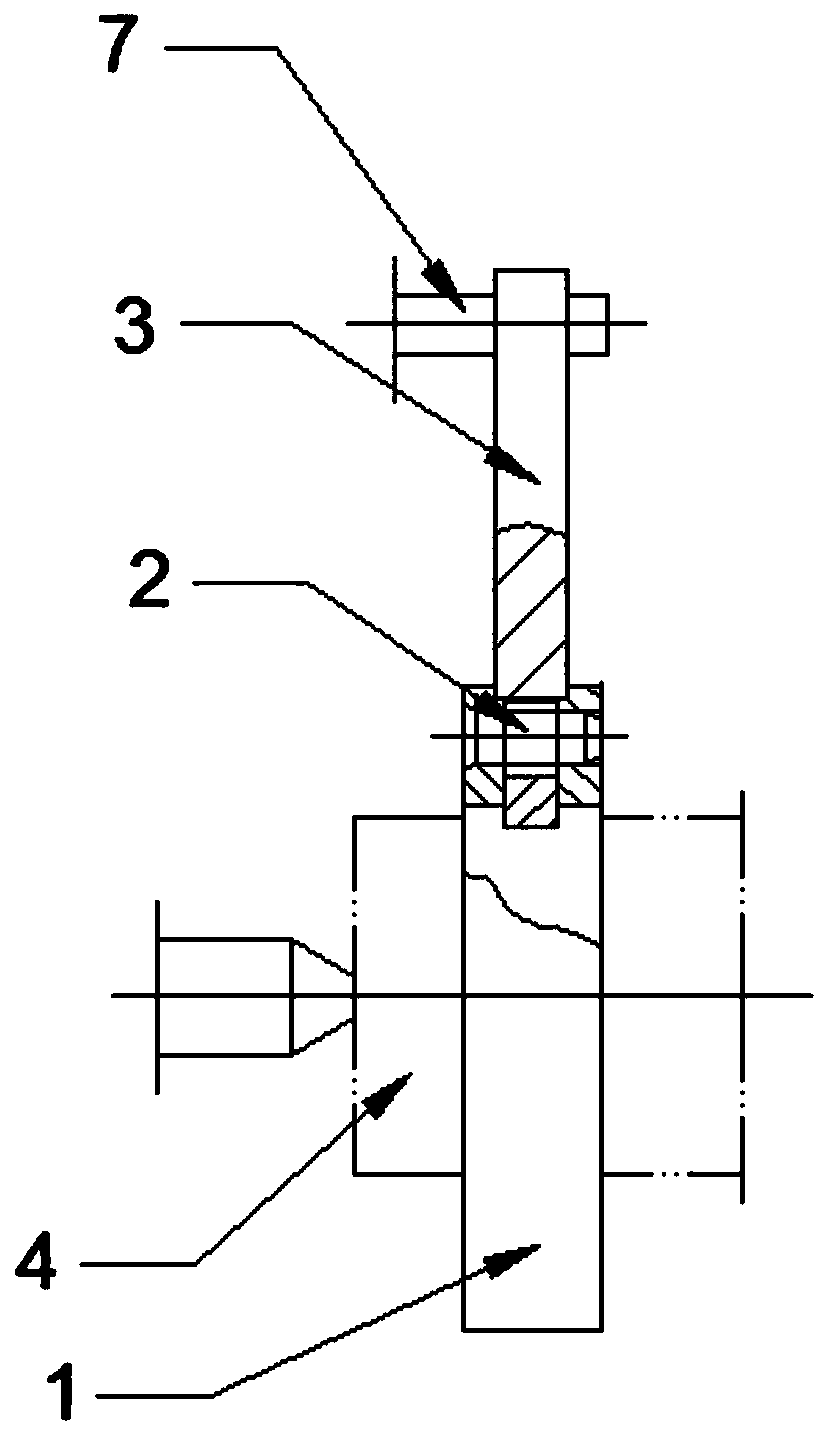

[0012] Such as figure 1 and figure 2 As shown, a fast self-clamping chicken heart fixture includes a chicken heart fixture 1, the upper end of the chicken heart fixture 1 is hinged to a lever 3 through a pin shaft 2, the workpiece 4 is clamped in the middle of the chicken heart fixture 1, and the lower end of the lever 3 is Serrated and obliquely cut with the outer surface of the workpiece 4, the outer surface of the heart-shaped jig 1 is fixed with a spring piece 6 by a screw 5, and the other end of the spring piece 6 is against the lever 3.

[0013] Further, the top end of the lever 3 is in contact with a driving rod 7, and the driving rod 7 is installed on a lathe.

[0014] The lever 3 is driven to rotate by the lever 7, and the oblique saw teeth at the bottom of the lever 3 are in contact with the workpiece 4 to clamp the workpiece. The spring piece 6 between the lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com