Outdoor three-position switch operating mechanism

A three-position switch and operating mechanism technology, applied in electrical switches, contact operating parts, contact driving mechanisms, etc., can solve the problems of difficulty in selecting the contact position, adding position confirmation contacts, etc., and achieves a large contact surface, Easy to install, easy to set up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

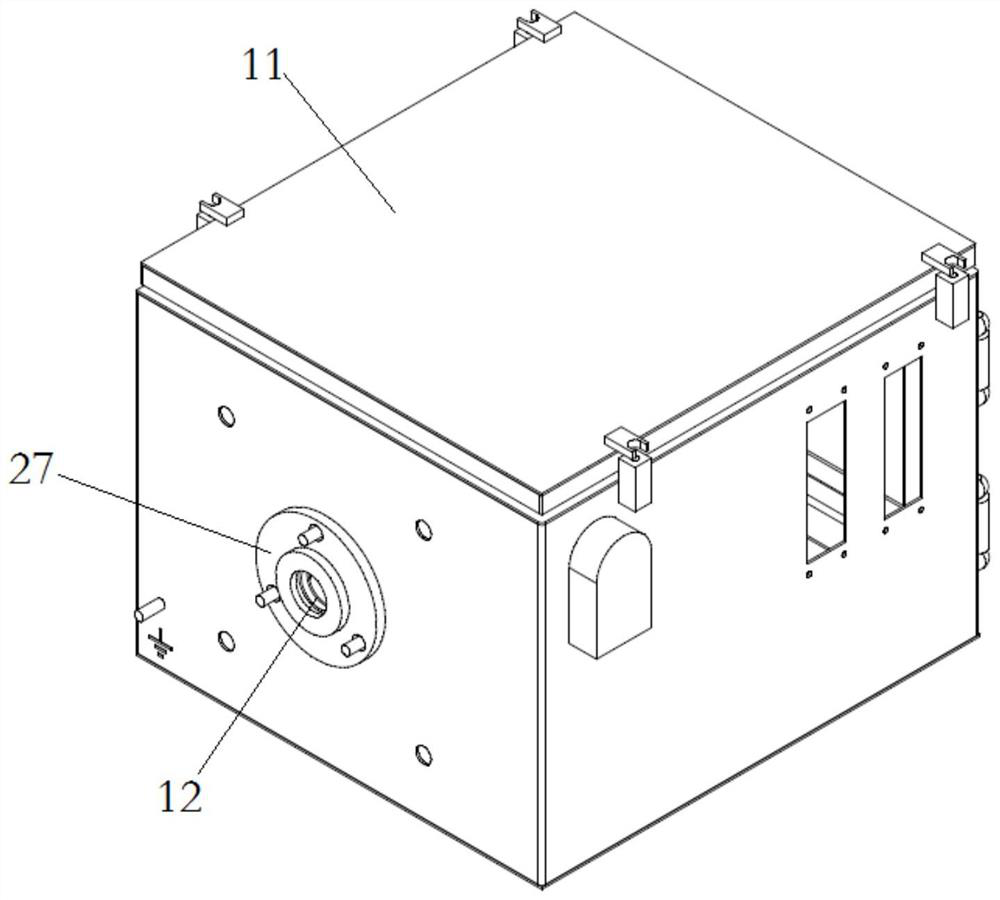

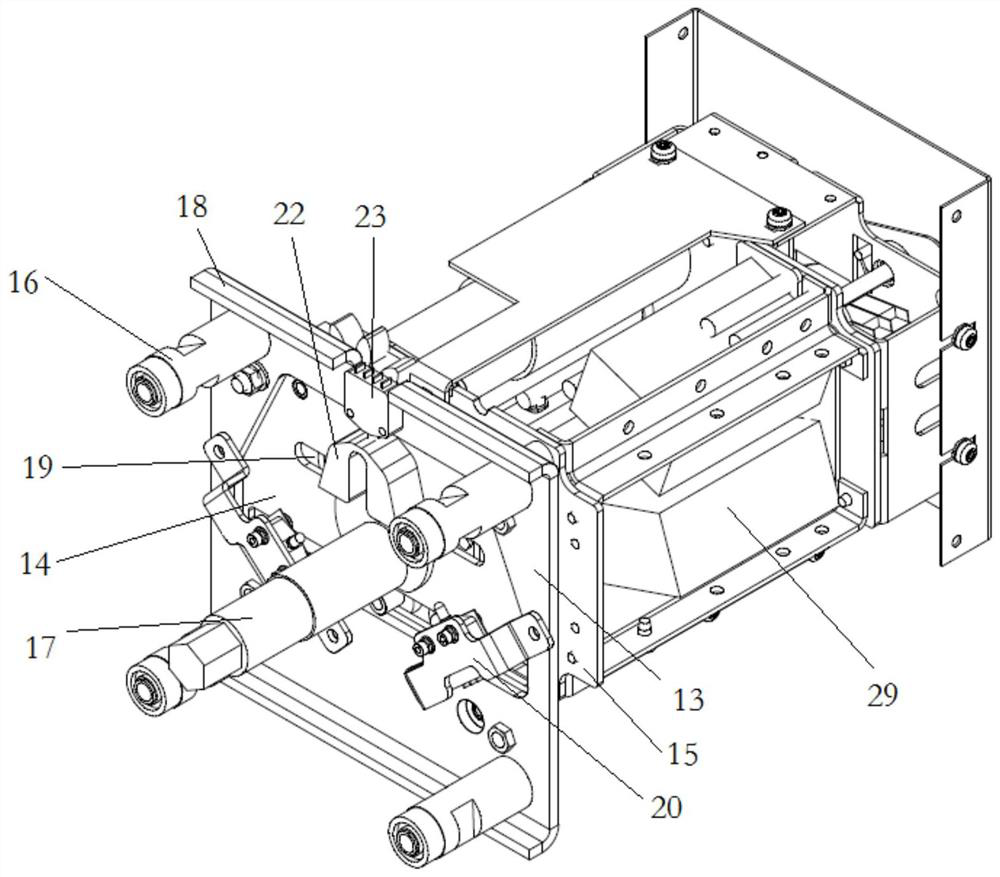

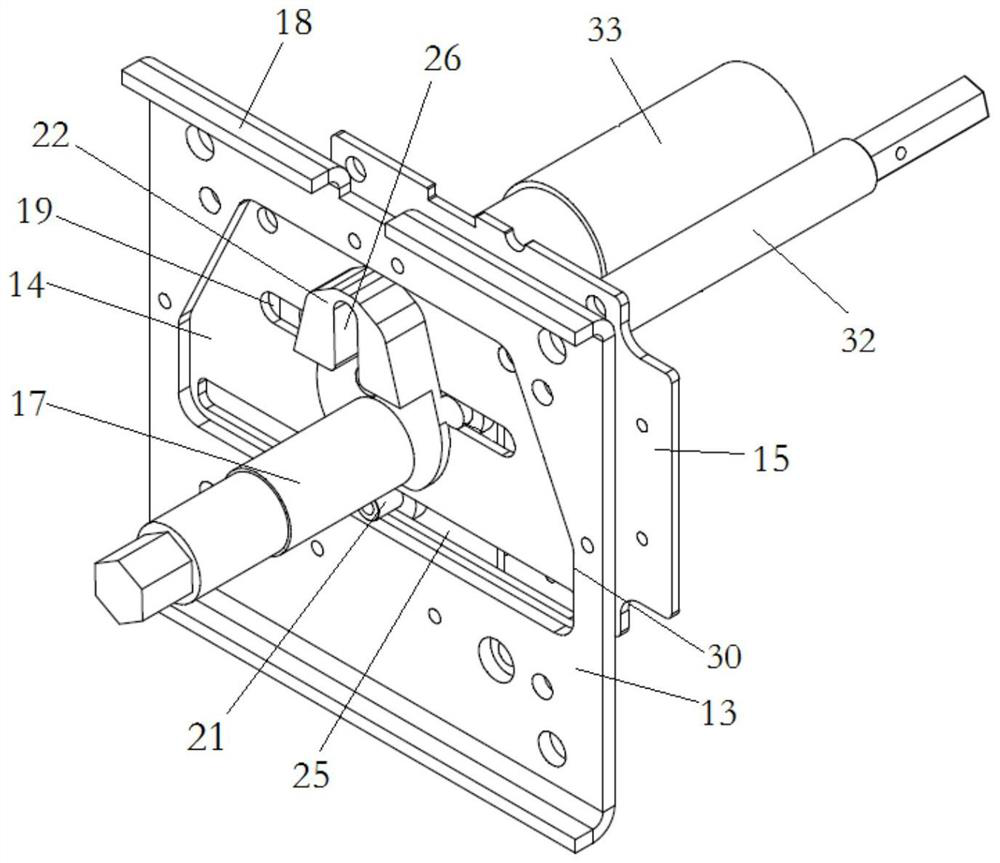

[0043] In this example, if Figure 1 to Figure 3 As shown, the outdoor three-position switch operating mechanism includes a protective box 11 and a mechanism body. The protective box 11 is a closed box for the mechanism body to fit into the outdoor environment. The protective box 11 is provided with a mechanism fixing plate 13 for the mechanism. The body is fixedly connected. Such as Figure 6 As shown, the mechanism body includes a transmission disc 31, which is engaged with the motor 33 gears for transmission. The transmission disc 31 is provided with a power transmission rod 32. On the mechanism connected to the transmission to provide a set of position confirmation contacts. The drive disc 31 is also provided with center-symmetrical guide pins opposite to each other. The guide pins are inserted into the switch chute with a specific profile on the switch slide 15 to drive the switch slide 15 to reciprocate. The switch sliding plate 15 behind the base plate 14 and the str...

Embodiment 2

[0051] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the thickened part is arranged at the overhanging end of the driving crank arm 22, and the microswitch 23 corresponding to the middle position corresponds to the extreme end of the driving crank arm 22, corresponding to the end of the driving crank arm 22. The microswitches 23 corresponding to the grounding position and the isolation position correspond to the two sides of the thickened part respectively. In this embodiment, the positions of the microswitches of the grounding position and the isolation position are changed so that the extreme end of the rotating driving crank arm respectively presses the micro switches corresponding to the middle position, the grounding position and the isolation position.

Embodiment 3

[0053] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the edge of the mechanism fixing plate 13 is provided with a forward folded edge 18, and the forward folded edge 18 is provided with an avoidance opening 28 for avoiding the position corresponding to the middle position. Micro switch 23. In this embodiment, an escape hole is provided directly above the mechanism fixing plate, and the escape hole is used for installing the installation support of the micro switch corresponding to the middle position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com