Standard mine warhead

A technology for warheads and sea mines, applied in mines, offensive equipment, weapon types, etc., can solve the problems of low generalization level of warheads, inability to directly borrow sea mine weapons and equipment, and affect the rapid formation of equipment, etc., to improve the generalization level, Effect of improving fall safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment provides a standard mine warhead to improve the generalization level of the mine warhead.

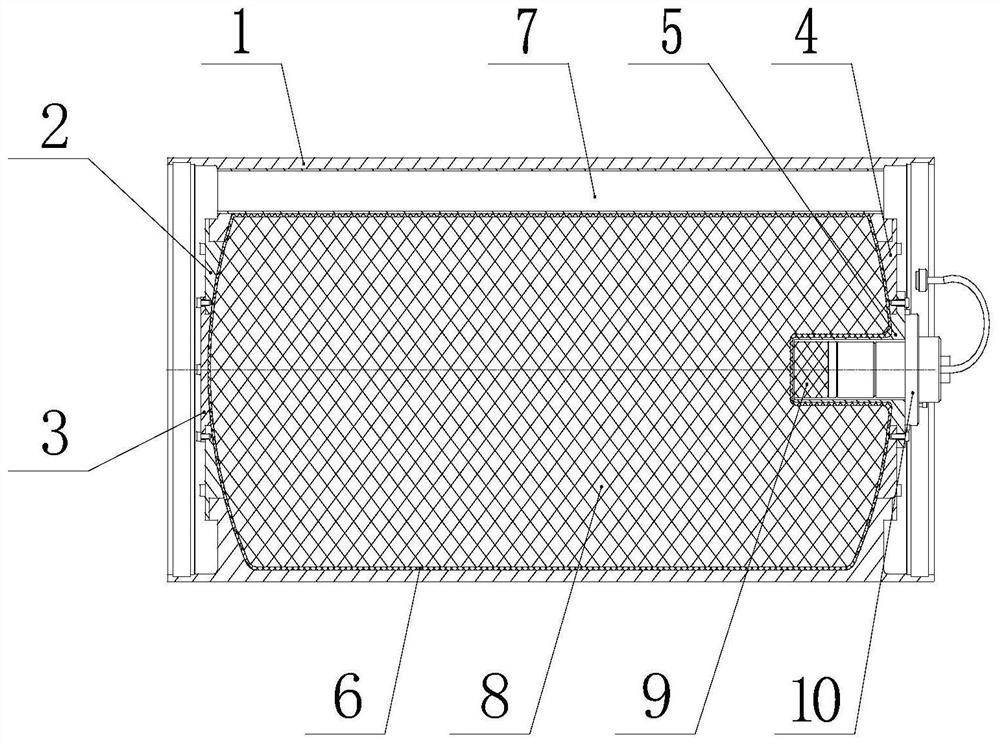

[0024] See attached figure 1 , the standard mine warhead includes: warhead shell 1, front drug retaining plate 2, charging hole cover 3, rear retaining drug plate 4, explosive cartridge 5, elastic lining 6, line pipe 7, low Sensitive high-energy main charge 8, expanding explosive column 9 and in-line detonating device 10.

[0025] The warhead casing 1 is a hollow cylindrical structure, and a front mounting flange and a rear mounting flange are respectively provided at both axial ends thereof.

[0026] The front drug retaining plate 2 is sealed and connected with the front mounting flange in the warhead shell 1;

[0027] The rear baffle plate 4 is sealingly connected with the rear installation flange in the warhead casing 1 .

[0028] Explosion expansion cartridge 5 is installed in the middle of rear baffle plate 4, expansion explosive column 9 and inline detona...

Embodiment 2

[0036] On the basis of Embodiment 1, the assembly steps of the standard mine warhead are described:

[0037] A. Assemble the warhead casing 1 and the wire-passing pipe 7 through external bevel welding or pressure riveting, and the wire-passing pipe 7 is arranged close to the inner wall of the warhead casing 1 .

[0038] B. After visually checking that the inner cavity is free of impurities, metal shavings and other impurities, install the rear baffle plate 4 and the explosive expansion cartridge 5 on the warhead shell 1 through screws in sequence.

[0039] C. The inner surface of the warhead shell 1 is bonded and laid with an elastic lining 6 (the position of the line pipe 7 is bonded and laid with an elastic liner 6 on the surface of the line pipe 7), and the overlapping parts are allowed to be partially trimmed after bonding to ensure The thickness of the bonding overlapping parts is uniform; after bonding the elastic liner 6 on the concave surface of the front drug blocking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com