Heat treatment device for plastic odor removal

A heat treatment device and plastic technology, applied in the field of plastic processing, can solve the problems of long heating cycle, high energy consumption, incomplete deodorization, etc., and achieve the effect of efficient deodorization and reduction of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention and are not intended to limit the scope of the present invention.

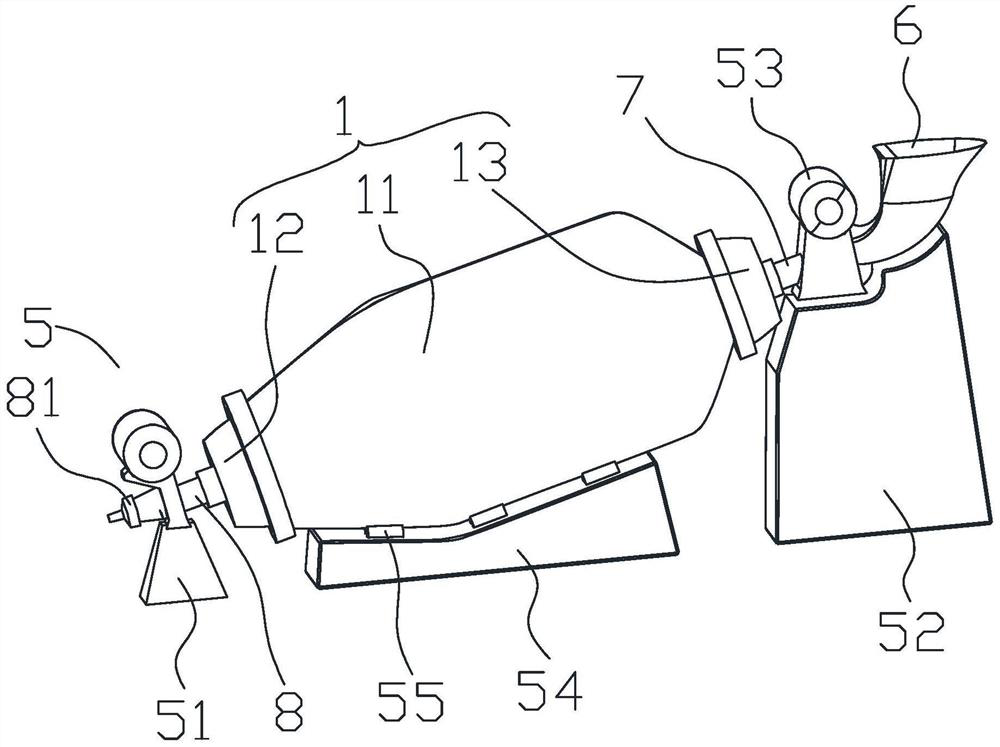

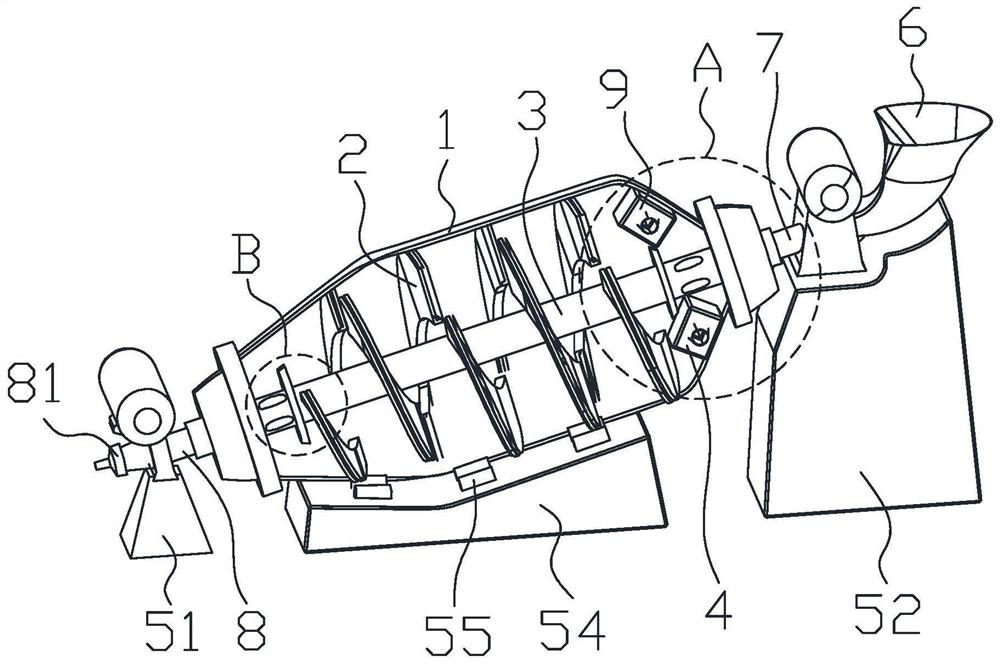

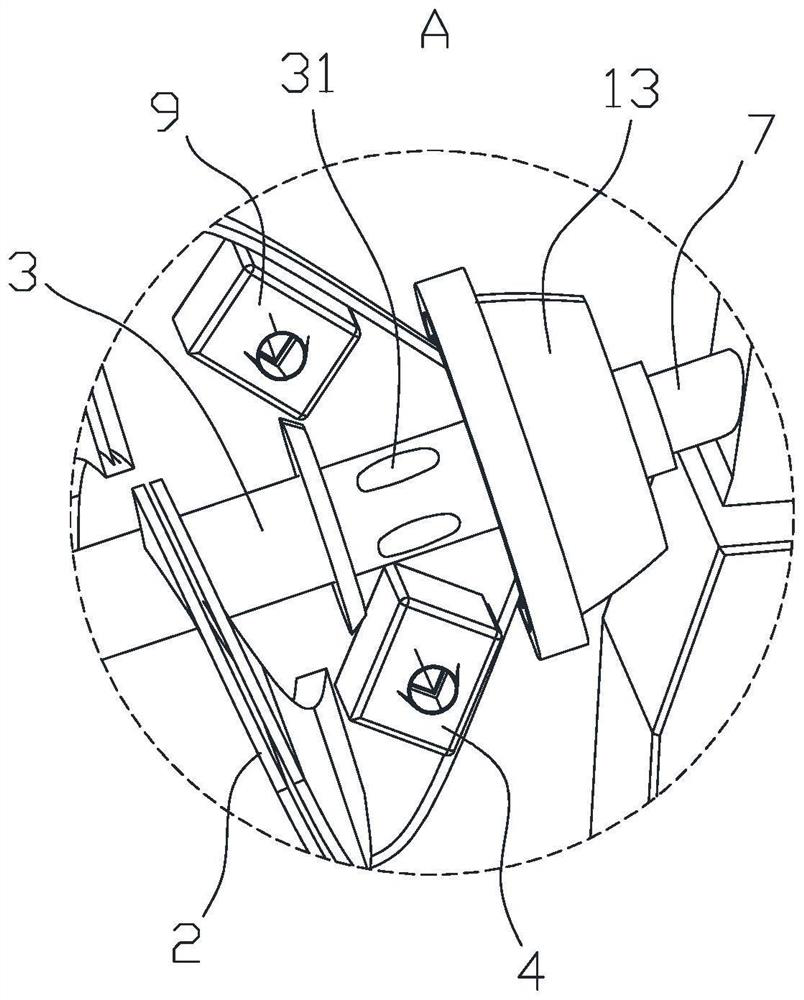

[0029] Please refer to figure 1 with figure 2 , the present invention provides a heat treatment device for deodorizing plastics, including a tank body 1, a spiral guide plate 2, a central tube 3, a heater 4, a vacuuming mechanism (not shown) and a driving mechanism 5.

[0030] The tank body 1 is arranged obliquely and has an airtight storage chamber for storing plastic particles. The spiral material guide plate 2 is fixed in the material storage chamber, and a spiral material lifting channel is formed between the spiral material guide plate 2 and the inner wall of the tank body 1 . The cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com