Novel power assembly of electric four-wheeler

An electric four-wheeled vehicle and powertrain technology, which is applied in the direction of electric power unit, power unit, vehicle parts, etc., can solve the problem of low power of in-wheel motor and in-wheel motor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

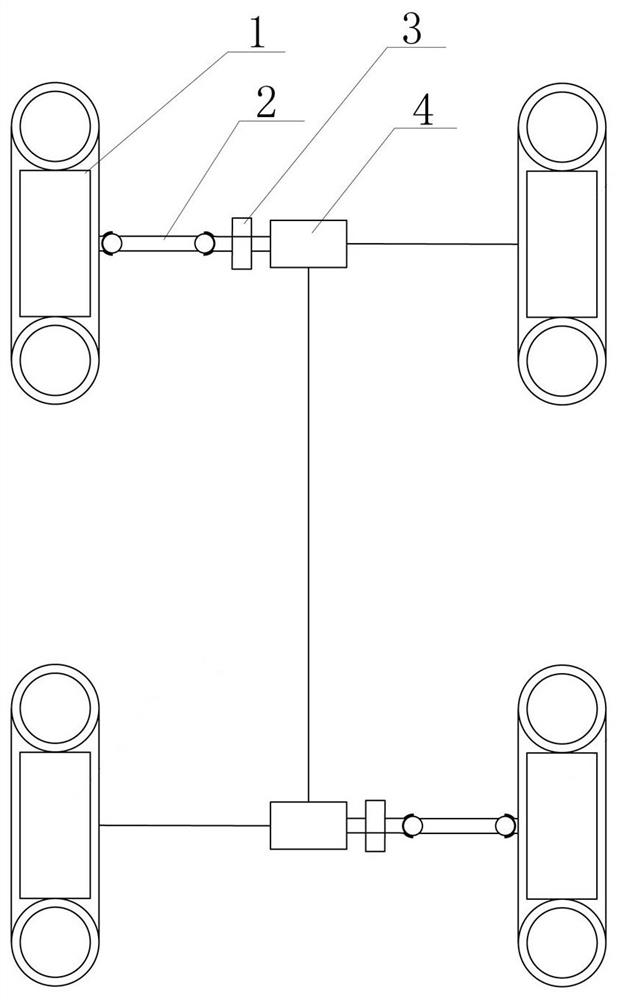

[0011] The structure of the left front wheel power assembly of the power assembly of a new type of electric four-wheel vehicle is: a cylindrical motor 4 for electric vehicles is used to connect a speed reducer 3, and the speed reducer is connected to the secondary differential speed of the chassis of ordinary front-drive fuel vehicles. The constant velocity drive shaft assembly 2 between the engine and the left front wheel 1. The cylindrical motor 4 for the electric vehicle, the speed reducer 3, and the constant velocity drive shaft assembly 2 between the differential and the left front wheel are integrated into a left front wheel power assembly. The powertrain of the right front wheel and the powertrain of the left front wheel have the same structure. The transmission system of a general rear-drive car includes: a gearbox, a differential, and the differential transmits power to the left and right through the left and right constant velocity drive shaft assemblies to the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com