Simultaneous measurement system and method for ammonia gas, nitric oxide and nitrogen dioxide in engine tail gas

A nitric oxide and nitrogen dioxide technology, applied in the measurement device and its measurement field, can solve the problems of increasing the occupied area, increasing the complexity of the detection system, and increasing the weight of the overall detection system, so as to achieve high detection accuracy and low mass The effect of widening the volume and detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in more detail below in conjunction with accompanying drawing example:

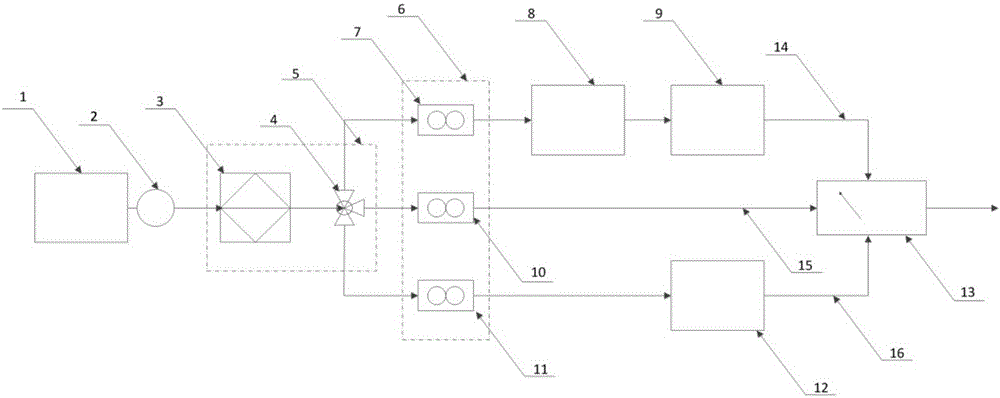

[0029] combine figure 1 , the present invention uses the tail gas collection system to collect the tail gas samples to be detected, controls the flow direction of the tail gas through the electronic control unit and divides the flow, and controls the tail gas flow of the three routes through the flow controller. The first line does not add any catalytic device, and uses CLD to directly detect NO in the exhaust gas. The reading is the NO concentration (ppm), which is recorded as CLD1. The total gas flow rate of the second line is the same as that of line 1. The tail gas passes through the ammonia catalytic conversion device and the NOx catalytic conversion device, converts NH3 into NO and converts NOx (NO+NO2) into NO, and is detected by CLD. The value should be the total concentration (ppm) of NOx and NH3, recorded as CLD2. The total gas flow rate in the third l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com