Embedded auxiliary fuel tank system

An auxiliary fuel tank and built-in technology, which is applied to the fuel tank of the power unit, weight reduction, etc., can solve the problems of blank integrated design, no technical data, and difficult maintenance and guarantee, so as to reduce the range of oil core variation and ensure reliable oil delivery , the effect of improving the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A built-in sub-tank system, such as Figure 12 As shown, it includes a storage cabin and a delivery cabin separated by a sealed partition 10. The upper part of the storage cabin is provided with a gravity refueling port 2 and an air pipe 4. One side of the storage cabin corresponds to the air pipe 4. There is an air circuit interface; the upper part of the delivery cabin is provided with an oil filling device 6, and one end of the oil filling device 6 passes through one side of the delivery cabin and is provided with an oil circuit interface; it also includes a Y-shaped pipe 3, The connecting pipe 9, the lower part of the storage cabin and the conveying cabin is communicated through the communicating pipe 9, and one end of the communicating pipe 9 located at the conveying cabin is provided with an upturning one-way valve, and the Y-shaped pipe 3 includes a connected A nozzle , B nozzle, C nozzle; the gravity filling port 2 is connected with the A nozzle of the Y-shaped ...

Embodiment 2

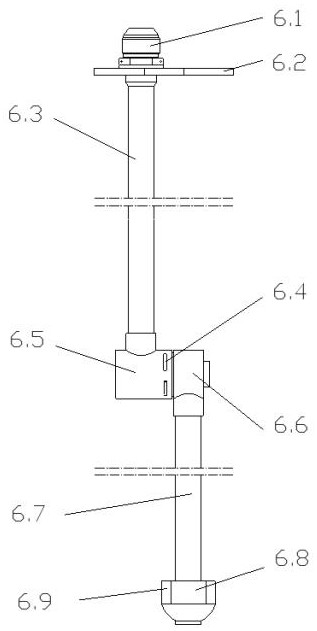

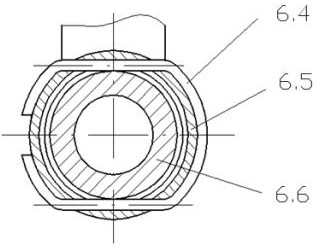

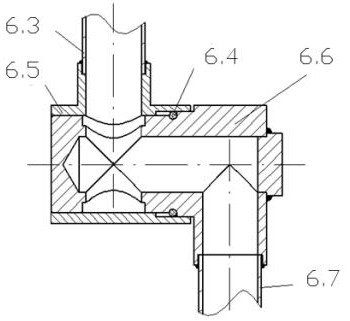

[0041] This embodiment is optimized on the basis of embodiment 1, such as Figure 1-Figure 3As shown, the oil filling device 6 includes a nozzle 6.1, an oil delivery pipe 6.3, a nipple sleeve 6.5, a pipe joint 6.6, an oil suction pipe 6.7, an eccentric block 6.8, and a counterweight 6.9; one end of the oil delivery pipe 6.3 passes through the nipple sleeve 6.5 It communicates with the pipe joint 6.6 and the oil suction pipe 6.7, the inner sleeve of the vertical elbow of the pipe joint 6.6 rotates in the pipe joint sleeve 6.5, and the other end passes through the delivery cabin and connects the nozzle 6.1; the free of the oil suction pipe 6.7 The end is provided with an eccentric block 6.8 and a counterweight 6.9.

[0042] Further, the oil filling device 6 also includes a U-shaped safety pin 6.4, the vertical elbow of the pipe joint 6.6 is provided with an annular groove along the circumference, and the upper and lower sides of the pipe joint sleeve 6.5 are respectively provide...

Embodiment 3

[0046] This embodiment is optimized on the basis of embodiment 1 or 2, as Figure 7 As shown, the gravity filling port 2 includes a main body, the top of the main body is provided with a blocking cover 2.4, and the side wall is provided with a vent nozzle 2.1, and the bottom sides of the main body are respectively provided with a scale 2.3, and adjacent scales 2.3 The slide between is provided with a float 2.2.

[0047] When the gravity filling port 2 was opened, the vent pipe nozzle 2.1 was connected to the atmosphere, and when the gravity fuel port 2 was closed, the vent pipe nozzle 2.1 was blocked. The ventilation nozzle 2.1 is connected with the A nozzle of the Y-shaped pipe 3 to ensure that the gas in the delivery cabin is discharged smoothly during gravity refueling. The gravity filling port 2 is provided with a float 2.2 in addition to the air nozzle 2.1, which has the function of indicating the liquid level, and is convenient for observing the full oil level during gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com