Floor packaging line and packaging method thereof

A packaging line and floor technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of low packaging efficiency, heavy workload, cumbersome and other problems, and achieve the effect of improving packaging efficiency, stable work and reasonable structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

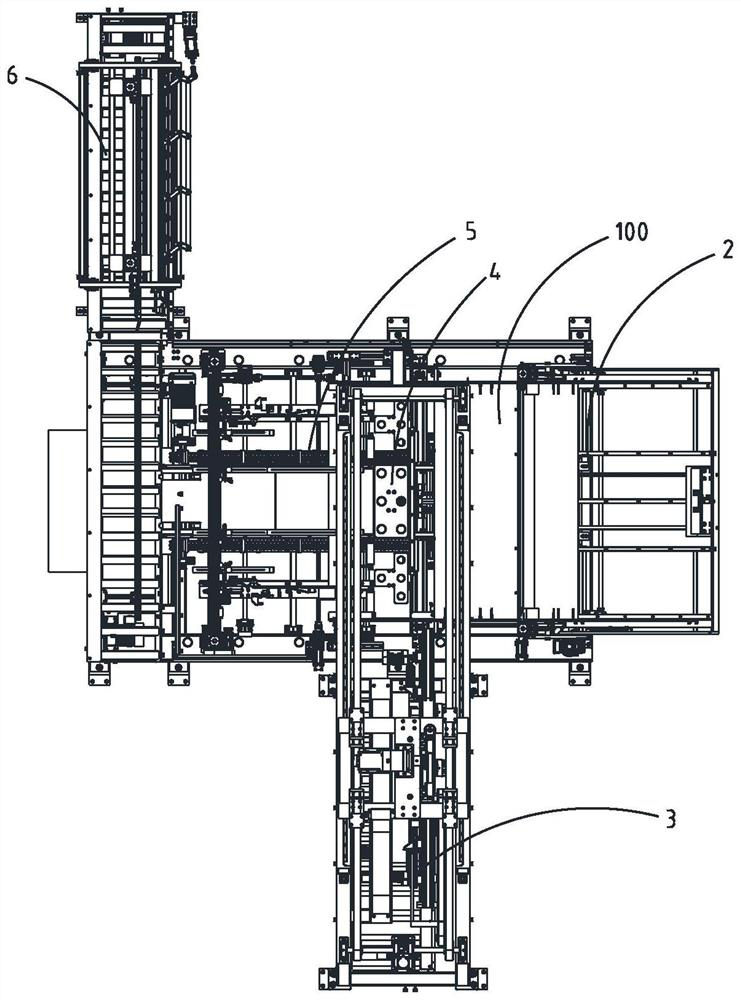

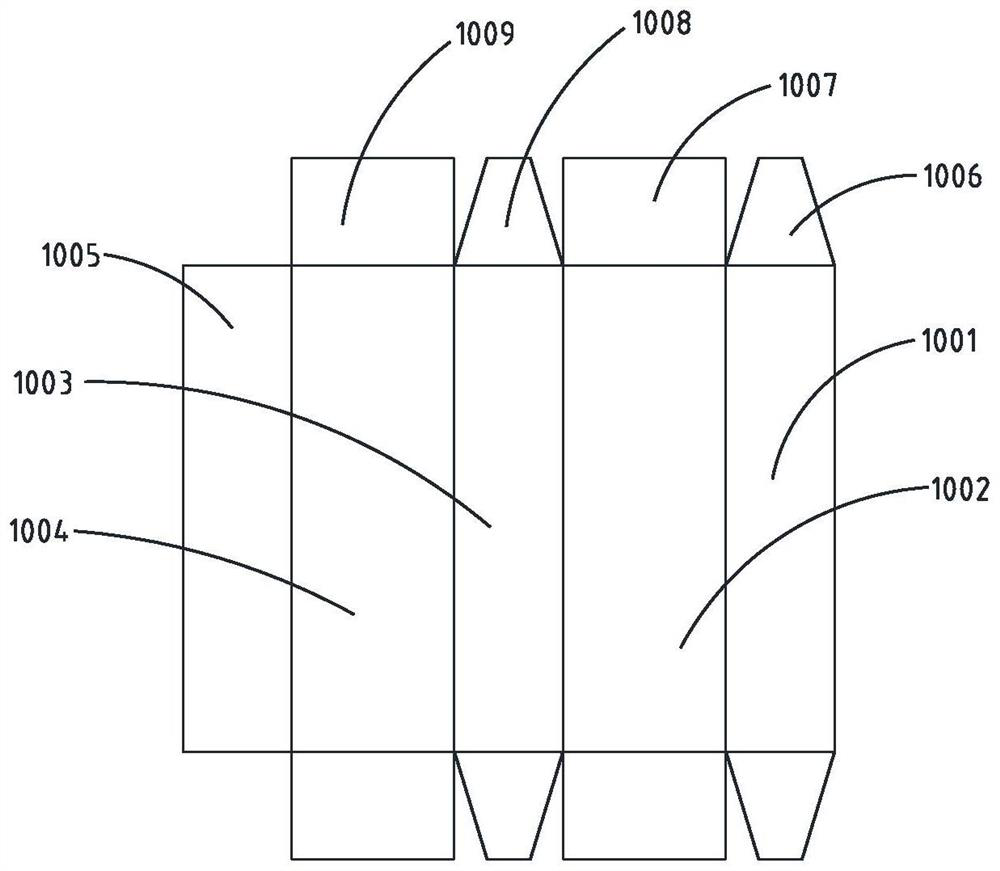

[0074] like figure 1 , 2 , 3, 4, 5, 6, and 7, a floor packaging line is used to pack the floor stack in a packing box formed by folding a carton board 100, and the carton board 100 has The set right side 1001, bottom surface 1002, left side 1003, top surface 1004 and right bonding surface 1005, two right side wings 1006 located on the front and rear sides of the right side 1001, two right wings 1006 located on the front and rear sides of the bottom surface 1002 The front and rear sides 1007, the two left wings 1008 located on the front and rear sides of the left side 1003, and the two front and rear bonding surfaces 1009 located on the front and rear sides of the top surface 1004 are characterized in that,

[0075] it includes:

[0076] A carton board loading device 2 suitable for loading the carton board 100 to the packing position;

[0077] An upper floor device 3 suitable for stacking the floor on the bottom surface 1002 of the carton board 100 at the packing position; ...

Embodiment 2

[0138] A packaging method of the floor packaging line as described in Embodiment 1, the method steps include:

[0139] The upper carton board device 2 puts the carton board 100 toward the packing position;

[0140] The upper floor device 3 stacks the floor on the bottom surface 1002 of the carton board 100 at the packing position;

[0141] The box pushing device pushes the carton boards 100 placed on the floor stack on the packing position to the box receiving position;

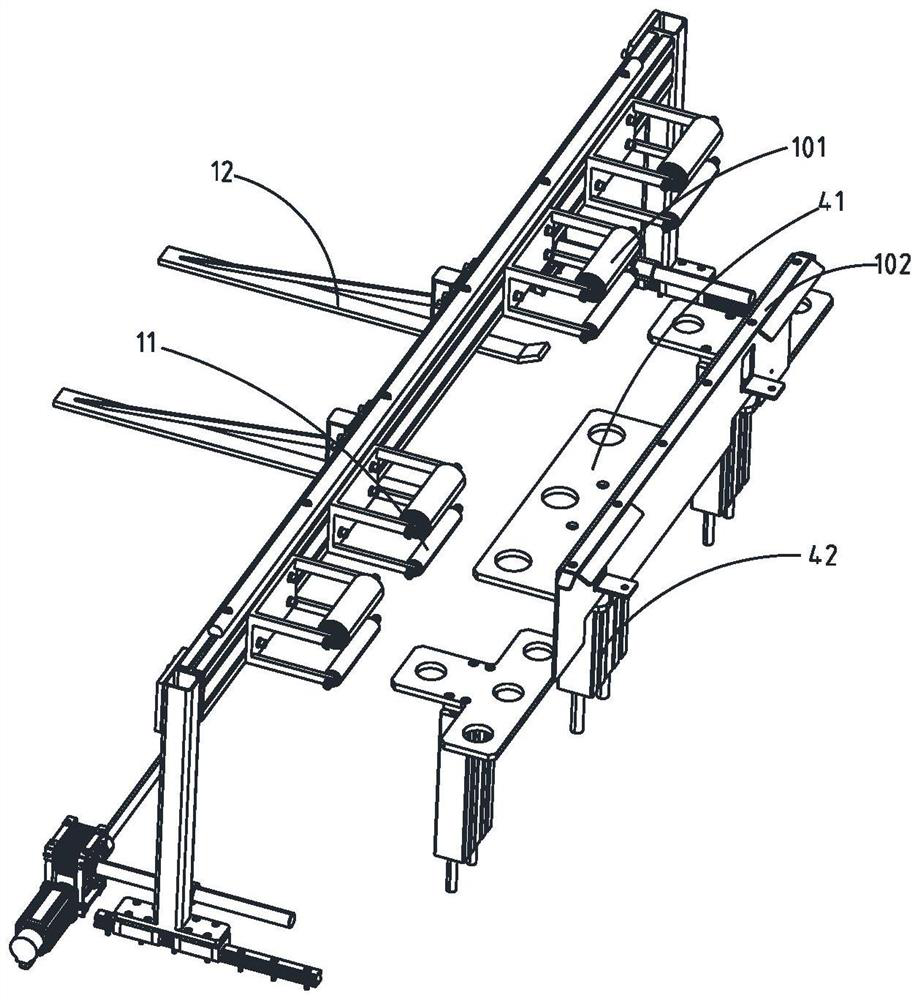

[0142] The box receiving device 4 receives the carton board 100 from the box position and drives the carton board 100 to descend so that the carton board 100 falls onto the transverse conveying device 5, and the left and right side folding devices fold the left side 1003 and the left side 1003 and The right side 1001 is turned up;

[0143] The horizontal conveying device 5 transports the carton board 100 from right to left to the top surface folding position, the right wing folding position, the left wing f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com