Mechanical hysteresis type vacuum maintaining energy-saving control device

A technology of vacuum maintenance and energy-saving control, applied in conveyor control devices, transportation and packaging, conveyor objects, etc., can solve the problems of low efficiency, waste of high-pressure air source, and high energy consumption, saving control operations and shortening working time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

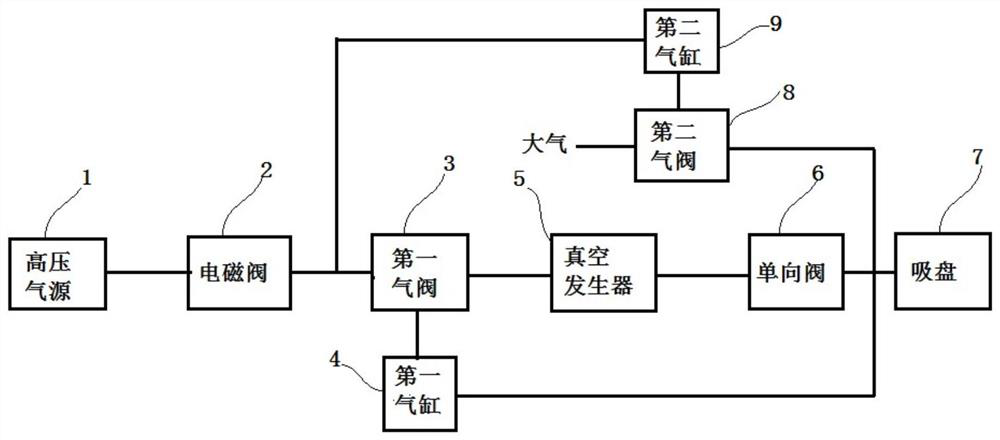

[0014] For the above-mentioned technical scheme, give preferred embodiments and describe in detail in conjunction with the drawings, see Figure 1 to Figure 3 .

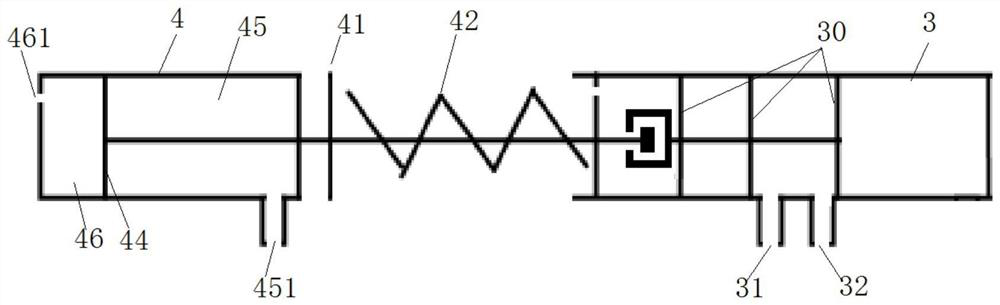

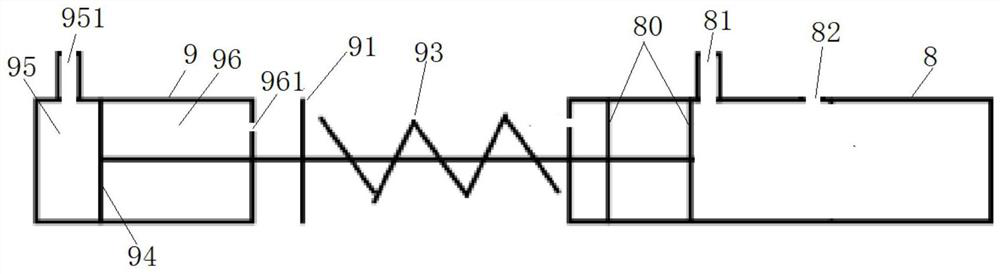

[0015] Mechanical hysteresis vacuum maintenance energy-saving control device, including high-pressure air source 1, solenoid valve 2, first air valve 3, first cylinder 4, vacuum generator 5, one-way valve 6, suction cup 7, second air valve 8, Second cylinder 9. The high-pressure air source 1 is generally an air compressor. The high-pressure air source 1 communicates with the solenoid valve 2 through the air pipe, the solenoid valve 2 is connected to the input end 31 of the first air valve 3 through the air pipe, and the output end 32 of the first air valve 3 is connected to the high-pressure air source input end of the vacuum generator 5 through the air pipe connected, the sealing ring 30 of the first air valve is driven to connect or disconnect the input end 31 and the output end 32 through the valve stem.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com