Near-infrared light-emitting material, preparation method thereof and LED light-emitting device

A luminescent material and near-infrared technology, used in luminescent materials, chemical instruments and methods, semiconductor devices, etc., can solve the problems of small spectral coverage, narrow half-peak width, low luminous intensity, etc., and achieve large spectral coverage and half-peak. Wide, high luminous intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The second aspect of the embodiment of the present application provides a method for preparing a near-infrared luminescent material, comprising the following steps:

[0050] S10. According to the chemical formula M x L y o 2 :R z The metering ratio obtains the compound raw materials of each element, and mixes them to obtain a raw material mixture; wherein, M is selected from at least one of Li, Na, and K; L is selected from Ga, In, Sc, Al, Y, Lu, and B At least one of R; R is selected from at least one of Cr, Yb, Mn, Er; 0

[0051] S20. Sintering the raw material mixture, and post-processing to obtain a near-infrared luminescent material.

[0052] The preparation method of the near-infrared luminescent material provided in the second aspect of the embodiment of the present application, according to the chemical formula M x L y o 2 :R z The metering ratio is used to obtain the compound raw materials of each element, and the mixing t...

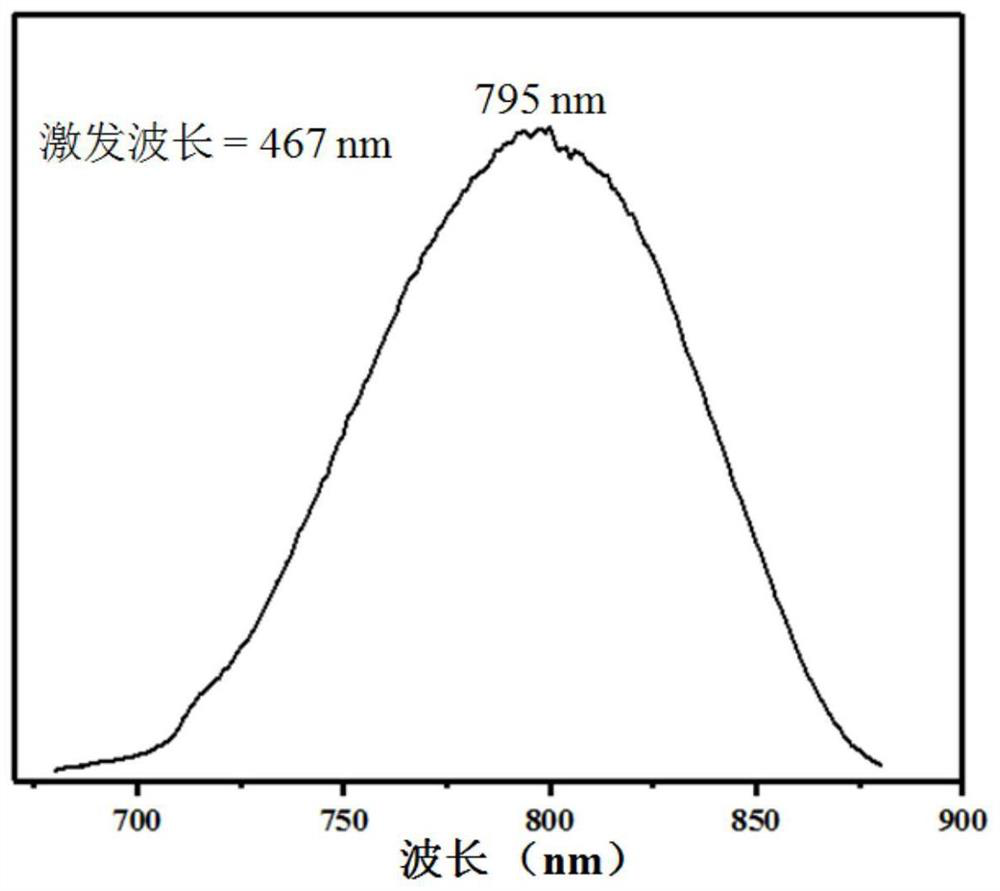

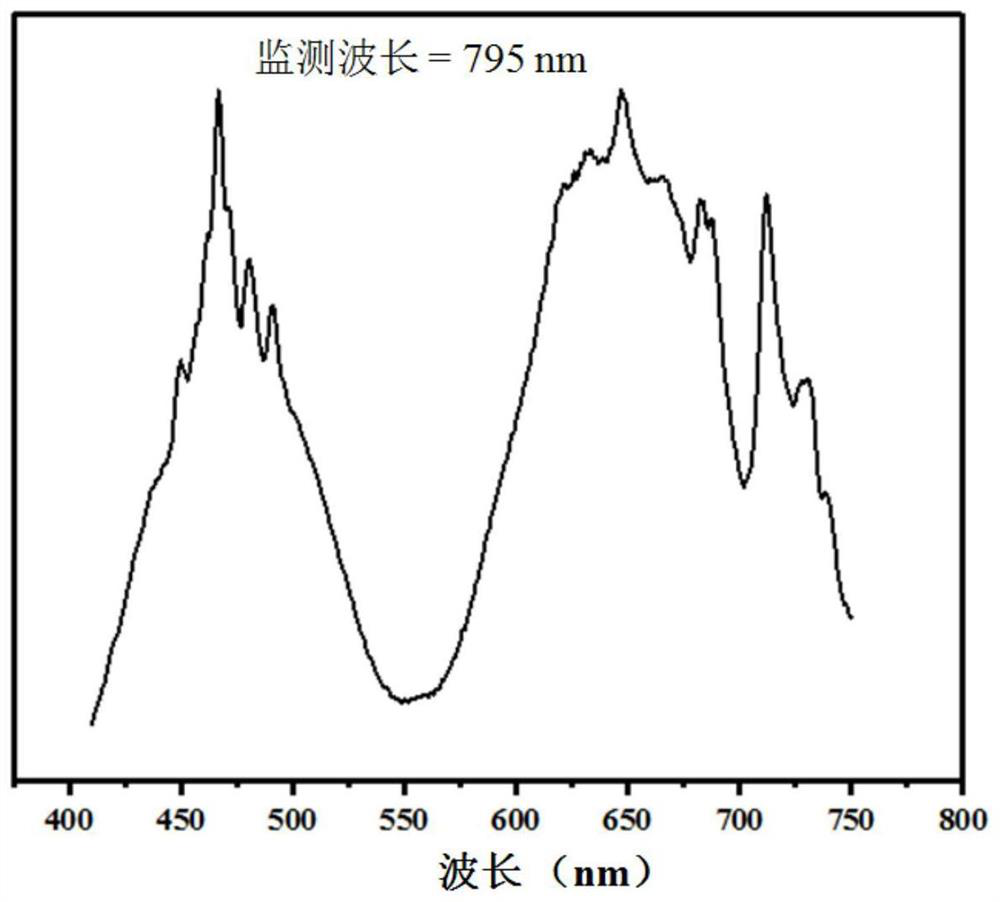

Embodiment 1

[0063] A near-infrared luminescent material with the chemical formula LiSc 0.97 o 2 :0.03Cr 3+ , its preparation includes the steps of:

[0064] According to the chemical formula LiSc 0.97 o 2 :0.03Cr 3+ The stoichiometric ratio, accurate weighing of Li 2 CO 3 、Sc 2 o 3 、Cr 2 o 3 The raw materials are placed in the agate grinder, and after grinding for 30 minutes, they are all transferred into an alumina crucible, sintered at 980°C for 7 hours in the air atmosphere of a high-temperature furnace, and cooled to room temperature with the furnace. , to obtain near-infrared luminescent materials.

[0065] A kind of LED light-emitting device, its preparation comprises the steps: After mixing the near-infrared light-emitting material prepared in Example 1 with the special A / B adhesive for LED packaging in proportion, packaging it on a 455nm blue light chip and drying it (due to the current commercially available The chip does not have 467nm, but has 455nm, and the near-in...

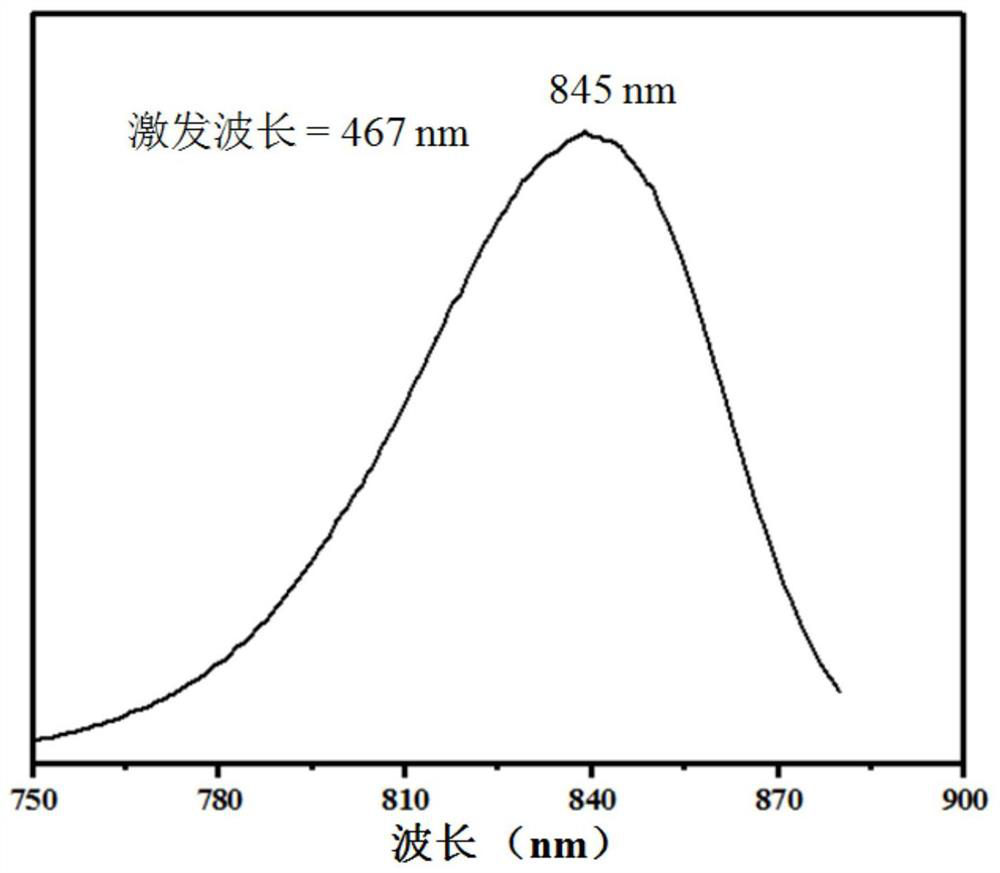

Embodiment 2

[0067] A near-infrared luminescent material with a chemical formula of LiIn 0.99 o 2 :0.01Cr 3+ , its preparation includes the steps of:

[0068] According to the chemical formula LiIn 0.99 o 2 :0.01Cr 3+ The stoichiometric ratio, accurate weighing of Li 2 CO 3 、In 2 o 3 、Cr 2 o 3 The raw materials are placed in the agate grinder, and after grinding for 30 minutes, they are all transferred into an alumina crucible, sintered at 1130°C for 7 hours in the air atmosphere of a high-temperature furnace, and cooled to room temperature with the furnace. , to obtain near-infrared luminescent materials.

[0069] An LED light-emitting device, the preparation of which comprises the steps of: mixing the near-infrared light-emitting material prepared in Example 2 with the special A / B glue for LED packaging in proportion, packaging it on a 455nm blue light chip and drying it to obtain an LED light-emitting device.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap