Environment-friendly cast-in-place pile construction device for constructional engineering

A technology for construction engineering and construction equipment, which is applied in construction, foundation structure engineering, sheet pile walls, etc., and can solve problems affecting the bearing capacity of cast-in-place piles, uneven dispersion of crushed stones, and cumbersome construction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

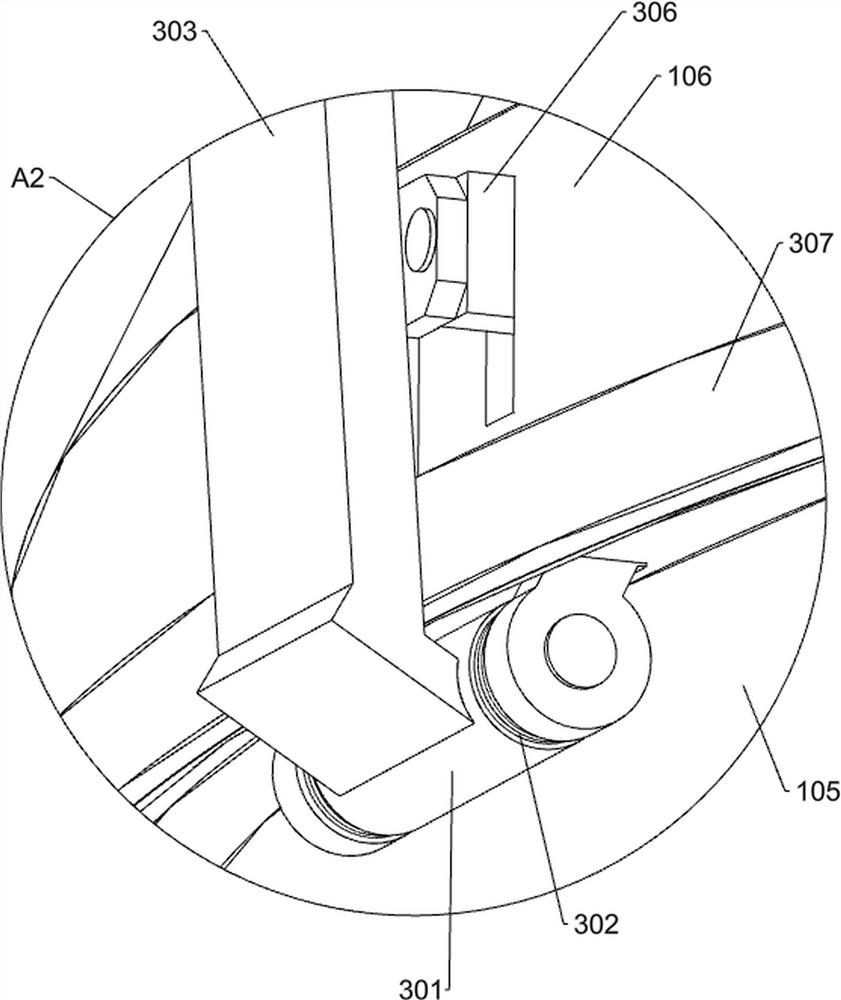

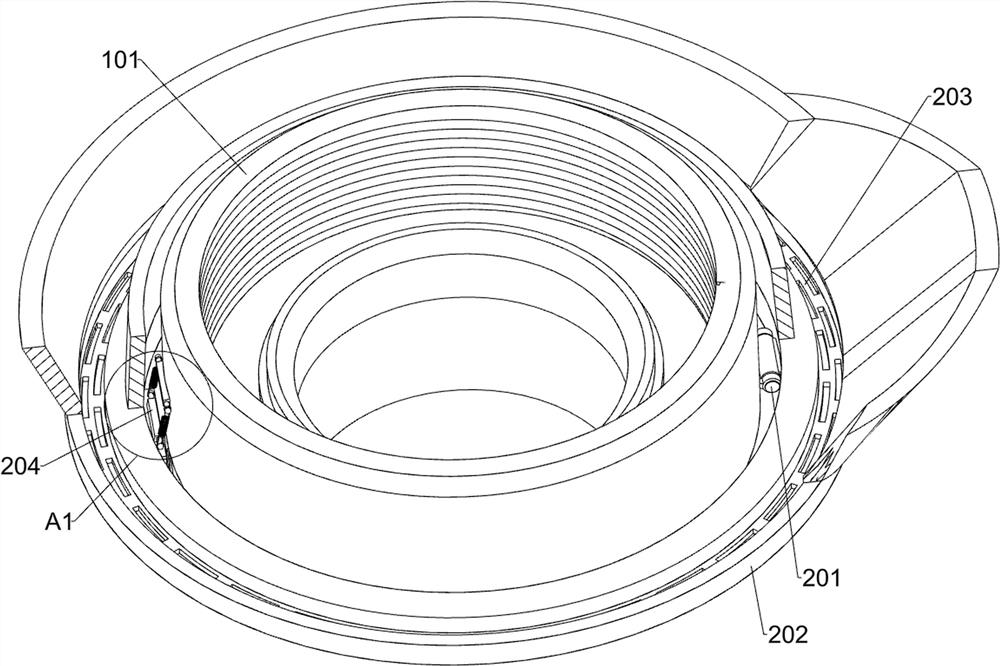

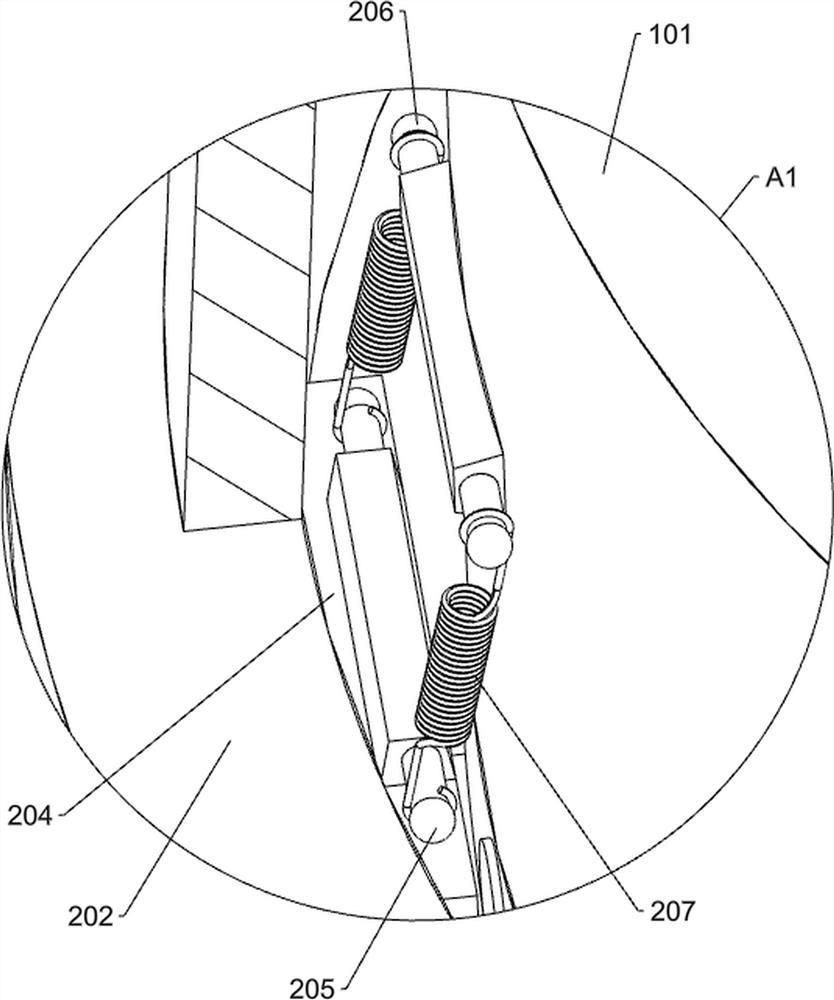

[0032] The utility model relates to an environmental protection cast-in-place pile construction device for construction engineering, such as Figure 1 , and Figure 5 - Figure 12 As shown in, it includes a filling unit, a vibration distribution unit, a bulk material unit, a slurry guide pipe 4 and a material guide pipe 5; The right side of the lower end of the slurry guide pipe 4 is fixedly connected with the material guide pipe 5; The lower end of the slurry guide pipe 4 is connected with a filling unit; The upper side of the filling unit is connected with a vibration distribution unit; The middle part of the filling unit is connected with a bulk material unit; The filling unit comprises a pipe sleeve 101, a slurry conveying pipe 102, an annular isolation plate 103, an annular support frame 104, an annular slider 105 and an annular bulk tray 106; The outer surface of the slurry guide pipe 4 is provided with a stiffener structure; The lower end of the slurry guide pipe 4 is connecte...

Embodiment 2

[0043] as Figure 1 , and Figure 5-14 As shown, this embodiment is further optimized on the basis of embodiment 1, and also includes a debris cleaning unit. The annular bulk tray 106 is provided with a debris cleaning unit. The debris cleaning unit includes a second shaft sleeve 401, a second torsion spring 402, a side fixing rod 403, a spike 404 and an anti-skid roller 405; Four second shaft sleeves 401 are respectively connected around the upper side of the annular bulk disc 106 through a rotating shaft; A second torsion spring 402 is fixedly connected between the two axial ends of the four second shaft sleeves 401 and the annular bulk disc 106, and the second torsion spring 402 is sleeved on the outer surface of the rotating shaft of the adjacent second shaft sleeve 401 shaft; A side fixing rod 403 is welded on the outside of the three second shaft sleeves 401; The upper sides of the three side fixing rods 403 are fixedly connected with a plurality of spikes 404; The outer ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com