Fabricated leveling assembly and leveling keel capable of being rapidly installed

A prefabricated and leveling technology, applied in covering/lining, construction, building construction, etc., can solve problems such as keel shaking, thread misalignment, etc., and achieve the effect of convenient clamping, ensuring stability, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

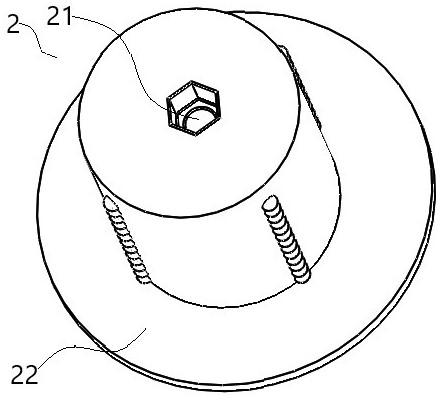

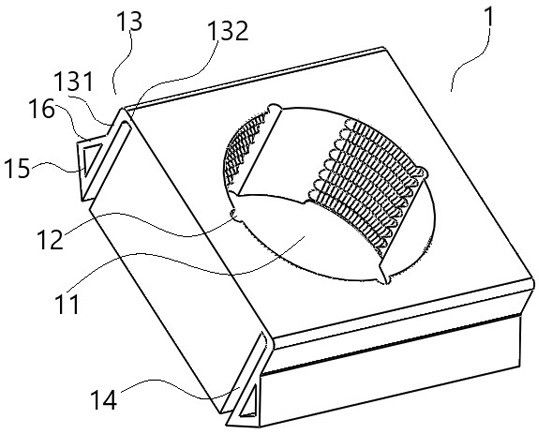

[0036] Such as figure 1 , figure 2 As shown, this embodiment is an assembled leveling assembly, including a base 1 and a screw 2 , one end of the screw 2 is connected to the building wall, and the other end is connected to the base 1 . The outer wall of the screw rod 2 is provided with several columns of external threads along the length direction of the screw rod 2 . The base 1 is provided with a through first channel 11, the inner wall of the first channel 11 is provided with several rows of internal threads and several first grooves 12 along the length direction of the first channel 11, and the external threads, internal threads and first grooves 12 are one One to one correspondence. Each first groove 12 is located on one side of its corresponding internal thread. The single-row internal thread of the base 1 in this embodiment is wave-shaped. The external thread can be inserted into the first groove 12 to make the screw 2 move along the length direction of the first gr...

Embodiment 2

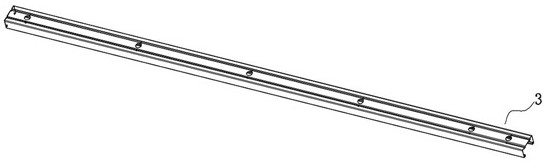

[0044] Such as Figure 1-5 As shown, this embodiment provides a quick-installable leveling keel, including the assembled leveling assembly described in Embodiment 1, and a keel 3 . The base 1 of the assembled leveling assembly is connected with the keel 3 . The keel 3 is provided with an accommodating groove for the base 1 to be plugged into. The accommodating groove of the keel 3 is engaged with the two protrusions of the first ear plate 131 .

[0045] The keel 3 of this embodiment includes a first keel plate 31 and two second keel plates 32 respectively located on both sides of the first keel plate 31 , the first keel plate 31 and the two second keel plates 32 surround and form a receiving groove. In order to facilitate the fixing of the screw rod 2 to the wallboard, the center of the first keel plate 31 is provided with a first through hole 311 . One end of the screw rod 2 away from the chassis 22 can be located in the first through hole 311, and the hexagon screw used f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com