OTP test system and method and storage medium

A technology of testing system and testing method, which is applied in the direction of electronic circuit testing, measuring electricity, measuring devices, etc., which can solve the problems of high requirements for testers and testing tools, increasing uncertainties in the testing process, difficult control of setting temperature and wind speed, etc. problems, to achieve the effect of enhancing human-computer interaction, improving test accuracy, and eliminating uncertain factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Provide a kind of OTP test system, described test system comprises:

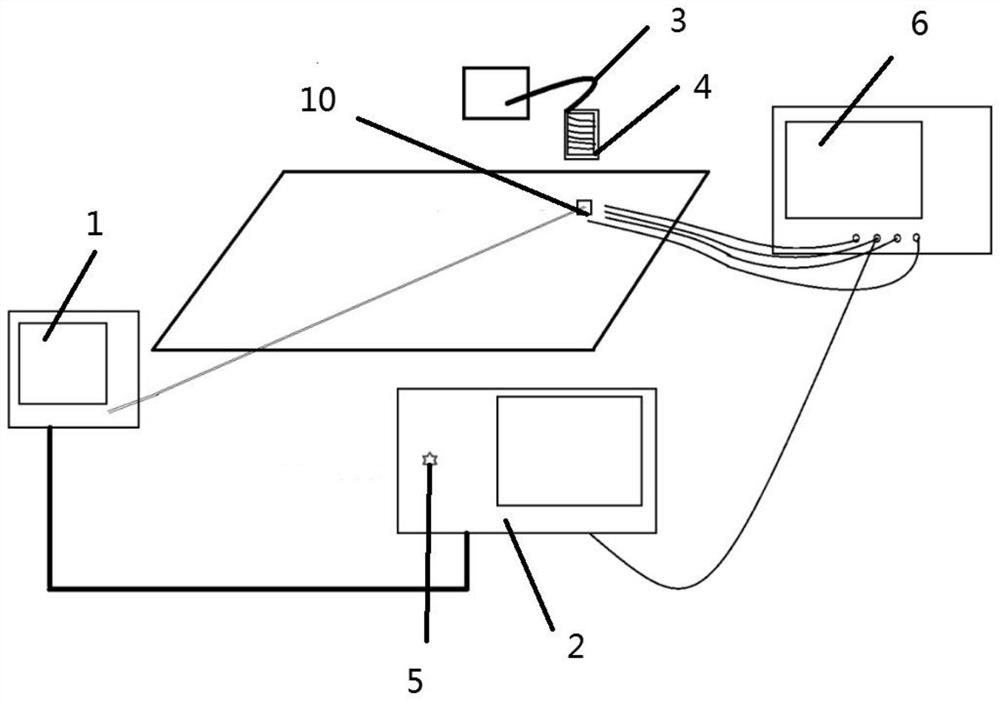

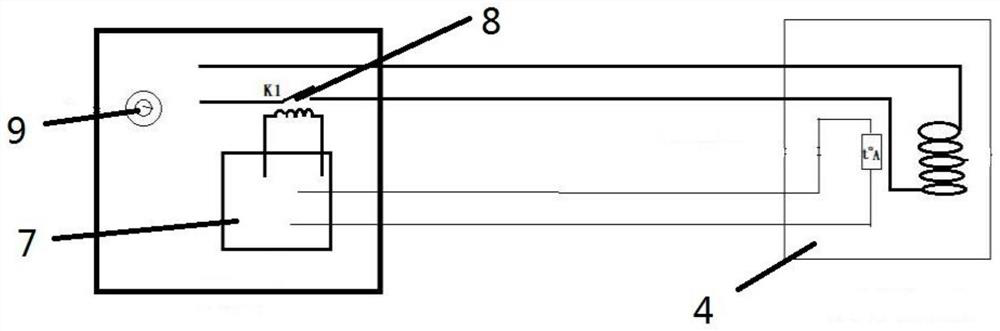

[0043]The chip to be tested 10, the chip to be tested 10 is embedded on the workbench, and the temperature measuring device 1 connected to the chip to be tested 10, specifically, the temperature sensing end of the temperature measuring device 1 is connected to the chip to be tested 10, and the temperature measuring device 1 One end is connected with a monitoring device 2, and the monitoring device 2 receives and monitors the first temperature data sent by the temperature measuring device 1. A heating device 3 is also included, and the heating device 3 is used for heating the chip 10 to be tested. Specifically, the heating device 3 includes a control unit and a heating cover 4 . The heating cover 4 is used to cover the chip 10 to be tested and heat the chip 10 to be tested, and obtain the second temperature data of the chip 10 to be tested by the temperature sensor in the heating cover 4, and then the ...

Embodiment 2

[0054] Corresponding to the above-mentioned embodiments, the present application provides an OTP test method, the test method comprising: detecting the first temperature data of the chip to be tested, and monitoring the first temperature data by a monitoring device;

[0055] Heating the chip to be tested to obtain second temperature data of the chip to be tested, and adjusting the heating rate of the chip to be tested according to the second temperature data received by the heating device;

[0056] When the monitoring device detects that the first temperature data exceeds the preset temperature threshold, an alarm signal is sent through the alarm.

[0057] Specifically, the specific implementation process: the temperature-sensing end of the temperature measuring device is pasted on the surface of the chip to be tested with an adhesive to detect the surface temperature of the chip to be tested, and the real-time temperature is transmitted to the monitoring device. The tester can...

Embodiment 3

[0059] A computer-readable storage medium is provided, which stores computer-executable instructions, and the computer-executable instructions are used to execute the above-mentioned OTP testing method.

[0060] In this embodiment, computer-readable storage media may include volatile and non-volatile, volatile, volatile, or Removable and non-removable media. For example, computer-readable storage media include, but are not limited to, volatile memories such as random access memory (RAM, DRAM, SRAM); and nonvolatile memories such as flash memory, various read-only memories (ROM, PROM, EPROM) , EEPROM), magnetic and ferromagnetic / ferroelectric memory (MRAM, FeRAM); and magnetic and optical storage devices (hard disks, magnetic tapes, CDs, DVDs); or other media now known or developed in the future capable of storing data for computer systems Computer readable information / data used.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap